- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

1910*720*1370mm, 1180*700*1100mm

-

Weight:

-

244 KG, 244KG

-

Machinery Function:

-

Cutter

-

Output product name:

-

LG-240 Two dimensional cutter

-

PACKAGE:

-

Standard Wooden Packaging

-

Advantage:

-

Multi-funcational

-

Type:

-

Two-dimensional dicer

-

Material:

-

304 Stainless Steel

-

Apply to:

-

all kinds of vegetable

-

Capacity:

-

500-2000kg/h

-

Application:

-

Restaurant,hotel,school,home,etc

Quick Details

-

Raw material:

-

Fruit, Vegetables

-

Marketing Type:

-

New Product 2021

-

Brand Name:

-

LiGONG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

1910*720*1370mm, 1180*700*1100mm

-

Weight:

-

244 KG, 244KG

-

Machinery Function:

-

Cutter

-

Output product name:

-

LG-240 Two dimensional cutter

-

PACKAGE:

-

Standard Wooden Packaging

-

Advantage:

-

Multi-funcational

-

Type:

-

Two-dimensional dicer

-

Material:

-

304 Stainless Steel

-

Apply to:

-

all kinds of vegetable

-

Capacity:

-

500-2000kg/h

-

Application:

-

Restaurant,hotel,school,home,etc

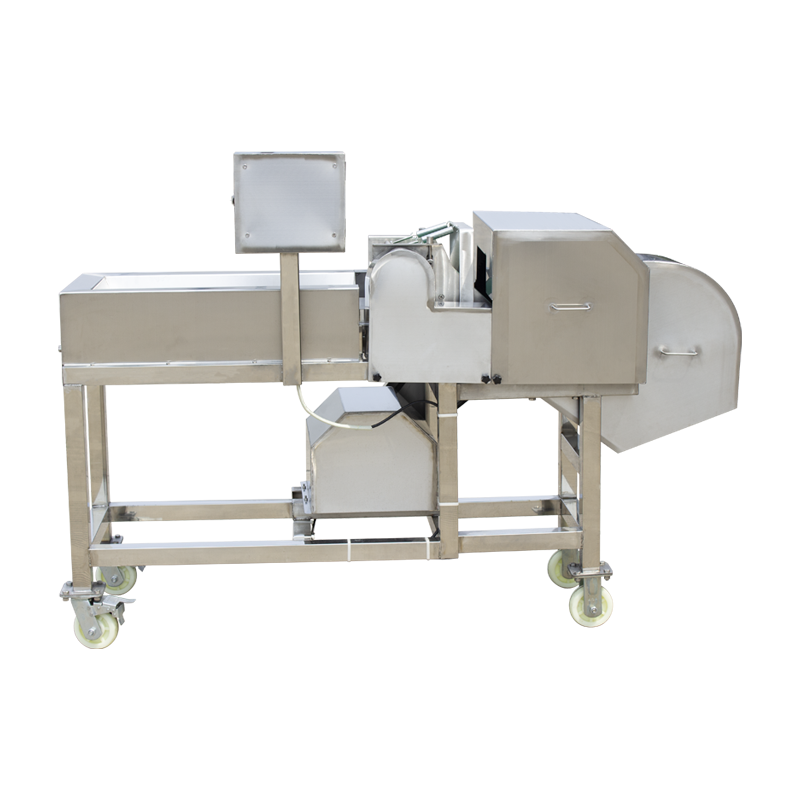

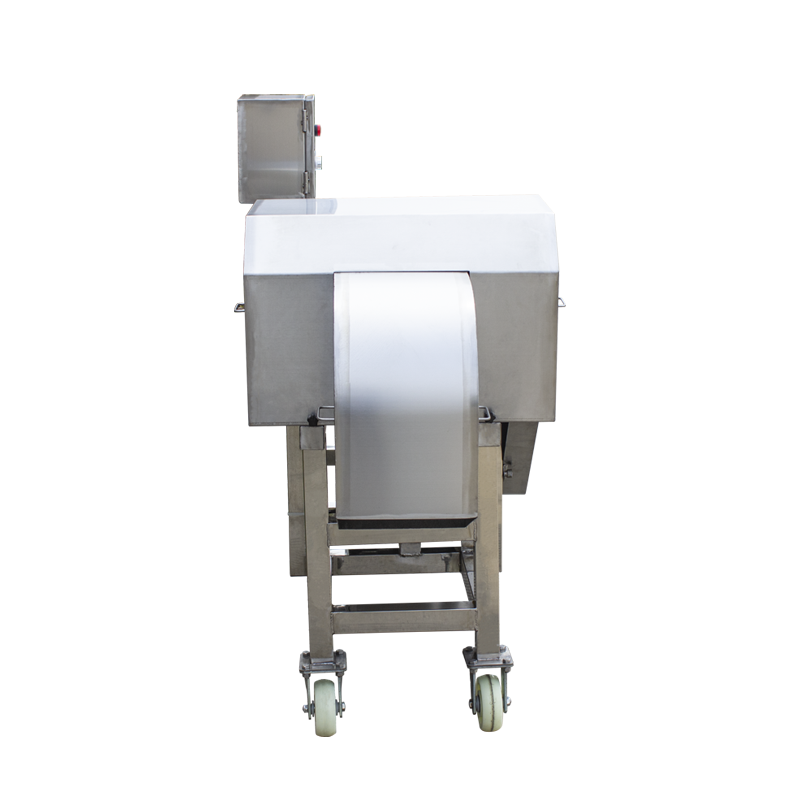

Product information

This machine is aimed at cutting large leafy vegetables such as spherical cabbage (cabbage) and Chinese cabbage into The requirements of squares or rectangles are optimized through trial and error. The machine Compared with similar products, the main advantage is that the material will not stay in the disc knife, horizontal The gap of the cutter meets the requirements of food hygiene.

Technical parameters

|

Dimension (mm) |

Exit size (mm) |

F eeding port size ( mm ) |

P ower (kw) |

|

1910*720*1370 |

350*255*490 |

300*950 |

2.2 |

|

Cutting Size |

Capacity ( k g/h ) |

Weight(kg) |

Capacity(kg/h) |

|

10-40 |

3000-8000 |

244 |

500-2000 |

working principle

The material walks forward on the conveyor belt of the feeding trough and is clamped by the upper pressure belt After compaction, the upper and lower auxiliary feed rollers are sent to the disc knife to cut into length during the relative rotation of the upper and lower auxiliary feed rollers. Strips, then move to the rotating cross cutter, which is cut into squares or long squares

Under the action of centrifugal force, throw along the discharge port.