- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

User Requirements

-

Weight:

-

200 KG

-

Name:

-

Commercial stainless steel distillery equipment for sale

-

Material:

-

Stainless Steel 304 / 316 / copper

-

Insolation:

-

80mm PU or rock wool

-

Heating method:

-

Electric And Steam or direct fire

-

Sizes and Parts:

-

Sizes and Parts details can be customized by customers

-

Thickness:

-

1.5mm ~ 3mm

-

Technology Advantage:

-

PU insulation, dimple jacket, cooling system ect

-

Surface:

-

Interior Surface is 3A Finish, Exterior is 2B Finish

-

Equipment Usage:

-

Beer Brewing, Beer Fermentation, Beer Production ect

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONSEN

-

Voltage:

-

Adjustable

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

User Requirements

-

Weight:

-

200 KG

-

Name:

-

Commercial stainless steel distillery equipment for sale

-

Material:

-

Stainless Steel 304 / 316 / copper

-

Insolation:

-

80mm PU or rock wool

-

Heating method:

-

Electric And Steam or direct fire

-

Sizes and Parts:

-

Sizes and Parts details can be customized by customers

-

Thickness:

-

1.5mm ~ 3mm

-

Technology Advantage:

-

PU insulation, dimple jacket, cooling system ect

-

Surface:

-

Interior Surface is 3A Finish, Exterior is 2B Finish

-

Equipment Usage:

-

Beer Brewing, Beer Fermentation, Beer Production ect

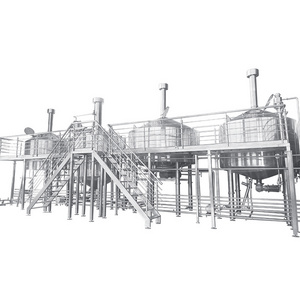

Commercial stainless steel wine tanks / brew machine / distillery equipment for sale !

Sanitary Stainless steel 304/316

conical vertical tank,

25% top space to avoid beer foam out;

dome top head, cone bottom;

Surface brushed, welding line polish sanding light belt;

dimple plate cooling jackets( on wall and cone);

With rotary CIP spray balls and arm;

Pt100 temperature sensor; dry hopping port on top head;

Sample valve in the cylinder;

separate outlets for yeast and clear beer, beer racking arm located in the conical part of the tank

Relief valve, Pressure regulating valve; Pressure gauge;

Glycol solenoid valves,

Stainless steel legs with bigger and thicker base plate, with screw assembly to adjust leg height

if you require, we can design with an extra arm on the opposite side of the tank than the CIP arm.

300L conical dimple cooling fermentation tank

Brewhouse is various in combination of vessels, of course to achieve the same four steps mashing,lautering, boiling, whirlpool, by special brewing intentions of brewer including wort output, wort gravity,sparging water, brews in certain time, brewing method etc. TonsenBrew Company accepts special design for these variations.

Our brewhouse system separated to 2 vessels, 3 vessels, 4vessels and 5 vessels, capacity from 100L to 20000L, use electric or steam heat. Semi-automatic control and easy to operate.

Two design variants – stainless steel with copper hats and jackets, full stainless steel brewhouse :

Two Vessels Brewhouse

Mash/Boil Kettle + Lauter Tun/Whirlpool Tun

Mash/Lauter Tun+ Boil Kettle/Whirlpool Tun

Three Vessels Brewhouse

Mash/Lauter Tun + Boil Kettle + Whirlpool Tun

Mash(kettle) Tun + Lauter Tun + Boil Kettle/Whirlpool Tun

PRODUCT FEATURES:

1.Desiging tanks and heating system according to craft, mash tank warming≥10℃/min

2.Energy saving stir structure : large cross-section impeller, 15r/min speed

3.Sieve plate of filter tank includes welding sieve plate and milling sieve plate.

4.Plow knife of filter tank separated to one foot, feet and bow plow knife

5.Wort boiling heat way includes steam jacket, interior heating and exterior heating.

6.Material includes stainless steel 304, 316 and red copper.

7.Stainless steel brewing platform & integrated stairs or ladder with adjustable foot pads for platform leveling

8.Standard Thermometers and Thermawell Adapters

CIP CLEANING

For hotel beer brewing equipment, you can adopt easy type CIP cleaning device including alkali tank, sterilization water tank and sanitary grade CIP pump. This kind of Vehicle fixes alkali, sterilization water tank CIP ump, pipes and valves on a small trolley operates flexible and simple, which can use for various types of small brewery equipment cleaning and disinfection that can disinfect thoroughly and have no dead angle. The equipment can be designed as manual ,semi-automatic operation according to the customers’ different requirement.

Cooling system

Cooling system includes ice water tank ,refrigerator,cooling pipeline, valves ect.

Cooling system is used in reducing the temperature of mass wort and fermenting, it’s a wasted energy system of beer equipment. Optimizing configuration of cooling system directly decide the low wasted energy in equipment running .

Cooling system adopts imported compressor, process safety, low malfunction rate, solve the customer’s worry, system pips is welded with pu pipe to keep warm, effective reduce the heat loss.

ONE-STOP SERVICE

Tonsen not only offer brewery equipment, but also provide beer brewery related products. Like Filling system(bottling / canning / kegging 0, filtering, washing ect. Welcome to check with us for what you want!

Jinan Tonsen Equipment Co.,LTD.

♦♦ Can supply CE certificate;

♦♦♦ Supply 100L/Batch---30,000L/Batch turnkey beer brewing system;

♦♦♦♦ Tell us how much beer do you need everyday. We offer you detailed specification, price, drawing and layout .

♦♦♦♦♦ We send engineer to install system and brew beer for you.

♦♦♦♦♦♦ Trade assurance is available.

Pre-sales Service:

1)Help the clients to confirm the configuration list

2)Supplying different beer craft specification

3)Designing the drawing according to the client’s floor plan and your requirement

4)Showing the detailed diagram of the tanks

After-sales Service:

1)We provide turnkey system, onsite installation service for brewery projects.

2)It’s available for us to send engineers to guide install

3)Life time guarantee

4)Online technology consult

1.Q: It’s the first year(1st year) for you to produce brewing equipments?

A: No. We worked in this business for many years but it’s the 1st year to generalize by alibaba

2.Q:How any years does your warranty ?

A:The main equipment for 3 years, auxiliary ones for 1 year.

3.Q;What’s your advantage ?

A:We are pioneer and know this business. Our 3 top-level technicists worked in this business over 10 years, 2 senior engineers worked over 8 years, workers average production experience is 3 years.

4.Q: Can you do OEM or ODM?

A: Yes, we can do.

5.Q: How to control temperature ?

A:PLC or digital display meter can control the temperature via connecting with the PT100 sensor.

6.Q: Is possible to supply installation in our country ?

A: Yes, we could supply engineer to supply installation guidance and training.

7.Q: Can your factory produce equipment according to our drawing or samples?

A: Yes, we can do.

We are factory supplied with good quality,more competitive price and installation service. Lifetime guarantee are assured.

Starting a business in hotel

* Less capital investment, quick return

* Flexible configuration, easy follow brewing

* Health, safety life style, and potential market

Investing a brewery in local region

* Cope with the hand-brew market demand

* Customize design,meet the diverse need

* Warranty for 3 years and lifetime repair guarantee

Increasing brewery production

* Rapid production increasing

* Volume flexible,easy installation

* Small investment help business thrive

For more project information please contact us Now!