Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Supplier Type:

-

manufacturer

-

Product name:

-

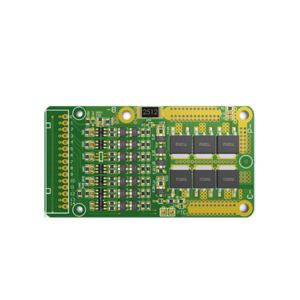

PCBA

-

Base Material:

-

FR-4,CEM-1,CEM-3,Polyimild,PTFE/Rogers

-

Number of layers:

-

1-48layer

-

Mini line Space:

-

3mi

-

Solder mask color:

-

Green/led driver circuit board

-

Board Thickness:

-

0.1-4mm

-

Testing Service:

-

AOI X-Ray Function Test

-

PCB Outline:

-

Square,circle,irregular(with jigs)

-

Surface Finishing:

-

HASL,OSP,Ag,ENIG,ENEPIG,Immersion silver/Tin

-

Certificate:

-

ISO9001

Quick Details

-

Model Number:

-

Customized PCBA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

STHL PCBA

-

Supplier Type:

-

manufacturer

-

Product name:

-

PCBA

-

Base Material:

-

FR-4,CEM-1,CEM-3,Polyimild,PTFE/Rogers

-

Number of layers:

-

1-48layer

-

Mini line Space:

-

3mi

-

Solder mask color:

-

Green/led driver circuit board

-

Board Thickness:

-

0.1-4mm

-

Testing Service:

-

AOI X-Ray Function Test

-

PCB Outline:

-

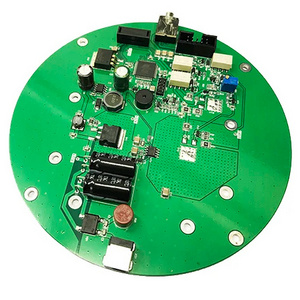

Square,circle,irregular(with jigs)

-

Surface Finishing:

-

HASL,OSP,Ag,ENIG,ENEPIG,Immersion silver/Tin

-

Certificate:

-

ISO9001

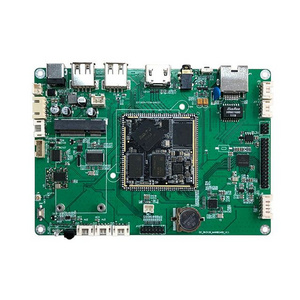

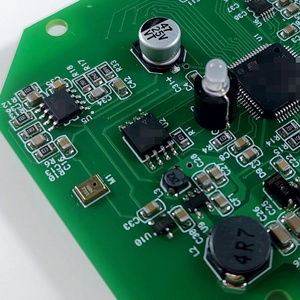

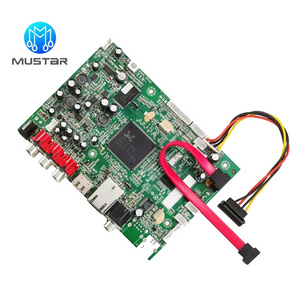

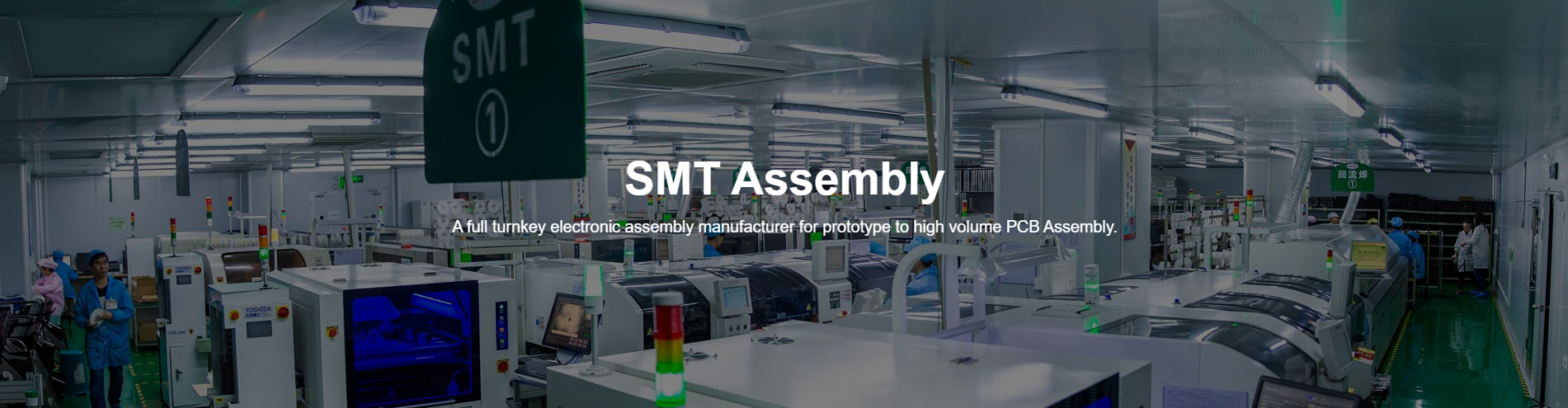

SMT Assembly

Surface Mount PCB Assembly

In surface mount PCB assembly, components are mounted directly on the PCB surface by automatic SMT machines.

This assembly technique is applied in many applications such as Communications, Security, Computer, Medical, Industrial, Automotive electronics and Smart home fields. With 6 automated PCB assembly production lines, we are capable of assembling low-volume PCBA prototype and high-volume PCBA orders.

We ensure consistent high-quality and accurate placement of components with the use of the latest SMT technology.

Our surface mount SMT PCB assemblies are known for their high mechanical strength, making them a reliable choice for high-speed circuit and decoupling applications.

SMT PCB Assembly Capabilities at STHL

We are equipped with advanced assembly and inspection equipment to support reliable PCB Assemblies.

Our highly trained and experienced staff make sure your projects completed faster with high quality.

Our capabilities in high-quality SMT PCB assembly services include, but not limited to:

– Ball Grid Array (BGA)

– Ultra-Fine Ball Grid Array (uBGA)

– Quad Flat Pack No-Lead (QFN)

– Quad Flat Package (QFP)

– Small Outline Integrated Circuit (SOIC)

– Plastic Leaded Chip Carrier (PLCC)

– Package-On-Package (PoP)

– Small Chip Packages (pitch of 0.2 mm)

– AOI inspection

– X-Ray Inspection

– Ultra-Fine Ball Grid Array (uBGA)

– Quad Flat Pack No-Lead (QFN)

– Quad Flat Package (QFP)

– Small Outline Integrated Circuit (SOIC)

– Plastic Leaded Chip Carrier (PLCC)

– Package-On-Package (PoP)

– Small Chip Packages (pitch of 0.2 mm)

– AOI inspection

– X-Ray Inspection

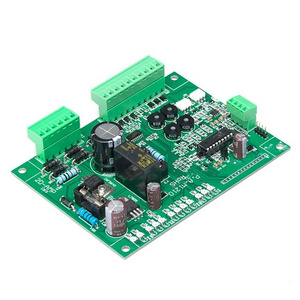

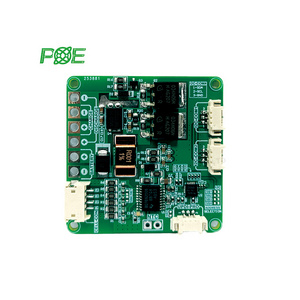

THT Assembly

Through Hole PCB Assembly

Through hole assembly with simple components is largely used on products such as power supplies, computer mother boards, security alarms, cleaning equipment and LED lighting products.

At STHL

Electronics

, skilled workers perform fast and quality THT assembly process for our customers. Our Lead Free wave soldering offers customers ROHS standard projects.

With 2 THT assembly lines and 2 post soldering lines, STHL Technology can offer both low-volume and high volume through hole assembly service.

Through-hole Assembly Capabilities at STHL

At STHL Assembly, we offer the following through-hole assembly services:

– Manual Insertion of Components

– Hand Soldering

– Automatic re-shape components

– THT assembly fixture for perfect quality and efficiency

– ESD tht assembly process

– RoHS Soldering using tin-lead solder

– Inspection and functional testing

– Conformal Coating

– Assembly for various shapes heats sinks, DC fan, Screw, wire, display…

– Device Programming

– Automatic & semi-automatic PCBA separator

– Wave soldering temp: Max. 300℃

– Manual Insertion of Components

– Hand Soldering

– Automatic re-shape components

– THT assembly fixture for perfect quality and efficiency

– ESD tht assembly process

– RoHS Soldering using tin-lead solder

– Inspection and functional testing

– Conformal Coating

– Assembly for various shapes heats sinks, DC fan, Screw, wire, display…

– Device Programming

– Automatic & semi-automatic PCBA separator

– Wave soldering temp: Max. 300℃

Advantages of Through-hole PCB Assemblies

|

1

|

Easier prototyping: through-hole has become an industry-standard because of its reliability. More to being reliable, through-hole components can easily be exchanged.

|

|

|

|

|

|

|

|

|||||||

|

2

|

Strong connections: through-hole components can withstand mechanical or environmental stress as they run through the board rather than being secured to the circuit board surface.

|

|

|

|

|

|

|

|

|||||||

|

3

|

Superior power handling capability: through-hole soldering forms a superior bond between the circuit board and components. This makes the board perfect for larger components that will undergo high voltage and high current.

|

|

|

|

|

|

|

|

|||||||

|

4

|

Greater heat tolerance: owing to the high heat tolerance capability, through-hole PCB assembly is preferred for many products in power supply and military sectors.

|

|

|

|

|

|

|

|

|||||||

Cable and Wire Harness Assembly

Cable assembly is applied in a huge variety of industrial applications, which is as critical to your product as any other

electronic component. As a reliable electronics contract assembly factory, STHL Electronics offers a set of industry-leading solutions for wire and cable assemblies.

With the precision manufacturing of cable assembly components including handles, retention systems, connectors, and shielding in a wide range of materials and finishes, we have performed many successful cable assembly for many customers from various industrial applications.

electronic component. As a reliable electronics contract assembly factory, STHL Electronics offers a set of industry-leading solutions for wire and cable assemblies.

We source high-quality cables as per the exacting requirements of customers and provide them with highly efficient cable assemblies that help to leverage the overall operation of electrical and electronic products.

With the precision manufacturing of cable assembly components including handles, retention systems, connectors, and shielding in a wide range of materials and finishes, we have performed many successful cable assembly for many customers from various industrial applications.

STHL Cable and Wire Harness Assembly Services

Whether it is a simple wiring harness assembly, or customized wire harnesses and cable assemblies, STHL PCBA can provide precise solutions at competitive prices and fast lead time.

Each solution is customized to meet industry and regulatory stands. All our prospective customers can take advantage of the following cable and wire harness assembly services provided by us:

– Prototype development

– Connector tooling

– Wire leads and sets

– Assembly packaging

– Printing on heat shrink

– Automated wire processing

– Sonic welding

– Installation

– Testing

– Braiding

– Prototype development

– Connector tooling

– Wire leads and sets

– Assembly packaging

– Printing on heat shrink

– Automated wire processing

– Sonic welding

– Installation

– Testing

– Braiding

Type of Wires We Can Offer:

Copper wire:

solid or stranded

Fiber Optic wire: single-mode (9/125), multimode (62.5/125, 50/125), Duplex or Simplex, Aqua Fiber cables

Coaxial wire: RG6, RG58, RG59, RG136, RG179, etc

Multiconductor wire: UL2464, UL2725, UL20276, etc.

Single hook-up wire: UL1007, UL1015, UL1332, etc.

Flat Cable: Gray ribbon cable, rainbow IDE cable, twisted pair SCSI U320 cable, etc.

Wire Jacket: PVC, PE, PU, TPE/TPO, Teflon, Plenum

Wire Shape: Straight wire, twisted-pair wire

Conductor Material: Copper, copper alloy, aluminum alloy

Wire Plating: Tin over copper, Silver over copper

Cable & Wire Size: 30 AWG to 12 AWG of conductor

Wire Standard: UL/CSA approval or Non-UL

Brand wire: We support any brand wire for assembly, please provide us wire details such as manufacturer name and part number.

Fiber Optic wire: single-mode (9/125), multimode (62.5/125, 50/125), Duplex or Simplex, Aqua Fiber cables

Coaxial wire: RG6, RG58, RG59, RG136, RG179, etc

Multiconductor wire: UL2464, UL2725, UL20276, etc.

Single hook-up wire: UL1007, UL1015, UL1332, etc.

Flat Cable: Gray ribbon cable, rainbow IDE cable, twisted pair SCSI U320 cable, etc.

Wire Jacket: PVC, PE, PU, TPE/TPO, Teflon, Plenum

Wire Shape: Straight wire, twisted-pair wire

Conductor Material: Copper, copper alloy, aluminum alloy

Wire Plating: Tin over copper, Silver over copper

Cable & Wire Size: 30 AWG to 12 AWG of conductor

Wire Standard: UL/CSA approval or Non-UL

Brand wire: We support any brand wire for assembly, please provide us wire details such as manufacturer name and part number.

Cable & Wire Assembly Applications

|

Audio/Video

|

|

Fixture Wire

|

|

Sound/Security/Fire Alarm

|

|

|||

|

Battery Cable

|

|

GPS / Data Acquisition

|

|

Motor & Drive Cable

|

|

|||

|

Coaxial Cable

|

|

High Temperature & High Voltage

|

|

Multi-Conductor Cable

|

|

|||

|

Control Cable

|

|

Hook-up & Lead Harnesses

|

|

Power Cables & Portable Cords

|

|

|||

|

Data & Communications Cable

|

|

Industrial Automation Cable

|

|

Ribbon Cable

|

|

|||

|

DC Power Jacks & Plugs Cables

|

|

Lighting

|

|

RJ45 Telephone Cable

|

|

|||

|

Fiber Optic Cable

|

|

Medical

|

|

Sensor Cables

|

|

|||

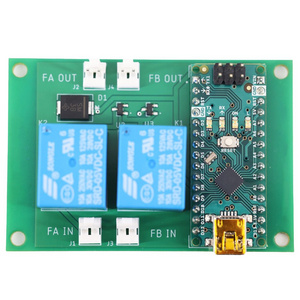

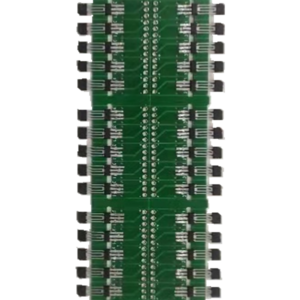

Electronic Box Build Assembly

Electronic box build assembly is a complex work comparing PCB assembly.

Few PCB Assembly factories have professional production line and experience to offer standard box build assembly service.

For low and medium volume box build assembly requests, we noticed some buyers divided works into different factories. PCB Assembly in factory A and box build assembly in factory B, which increases a lot of communication time and cost. The transportation also cause possible damage and delay.

The worse, frustrating thing may happen unexpected when you cut the work into two parties. When the final product with any issue, sometimes it’s hard to recognize the cause and responsible party, or it costs time and energy to analysis.

As a result, making your projects at STHL from SMT assembly to box build assembly is very cost-effective and fast to market.

The above products assembled by STHL, customers agree to show online.

STHL will not reveal any product information without approval.

STHL Box Build Assembly Services

We provide the following types of box build assembly services:

– Product Assembly

– Sub-level Product Assembly

– Competitive price both plastic and metal cases

– Complete product testing including functional testing and aging testing.

– Software programming

– Complete system integration

– Packaging (gift box packing)

– Sealing packing and vacuum packing

– Labeling including barcoding, SN number, mac address…

– Warehousing & drop shipment

– Product Assembly

– Sub-level Product Assembly

– Competitive price both plastic and metal cases

– Complete product testing including functional testing and aging testing.

– Software programming

– Complete system integration

– Packaging (gift box packing)

– Sealing packing and vacuum packing

– Labeling including barcoding, SN number, mac address…

– Warehousing & drop shipment

Start Your Box Build Assembly At STHL

If you have electronic box build assembly requirements, reaching out to STHL Technology is a great idea. As a part of our

services, we will offer you a free quote and some useful information as per our assembly experience.

services, we will offer you a free quote and some useful information as per our assembly experience.

We also assure you that we will never reveal your designs elsewhere with NDA agreement. Start your box build assembly projects at STHL by offering the below information:

|

1

|

Bill of Materials (BOM)

|

|

|

|

|

|

|

||||||

|

2

|

3D CAD model

|

|

|

|

|

|

|

||||||

|

3

|

The process of assembling

|

|

|

|

|

|

|

||||||

|

4

|

Sample Unit (If you have, it will speed up the whole process.)

|

|

|

|

|

|

|

||||||

|

5

|

Testing Method

|

|

|

|

|

|

|

||||||

|

6

|

Packaging & Shipping information

|

|

|

|

|

|

|

||||||

Contact us

GET QUOTATION NOW, PLS CONTACT:

Ms Alice

alice@firstpcba(dot)com

Mobile/WhatsAPP/Wechat: +86 13510188049

Hot Searches