- Product Details

- {{item.text}}

Quick Details

-

Pre-cooling time:

-

30~40min

-

power:

-

1.1+4kw

-

External dimensions:

-

6000*1900*2500mm

-

Material:

-

Stainless Steel

-

Capacity:

-

2000chicken/per Hour

-

Processing:

-

Screw Chiller Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Product name:

-

Chicken Plucker Poultry Feather Plucking Machine Slaughter Equipment

-

Model:

-

GGJ-6000

-

Pre-cooling time:

-

30~40min

-

power:

-

1.1+4kw

-

External dimensions:

-

6000*1900*2500mm

-

Material:

-

Stainless Steel

-

Capacity:

-

2000chicken/per Hour

-

Processing:

-

Screw Chiller Machine

Small Commerical Quail Feather Removing Chicken Plucker Machinery Poultry Feather Plucking Machine Slaughter Equipment

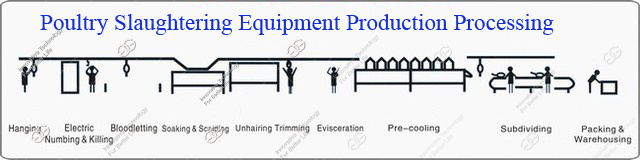

Chicken Slaughter Processing Process:

Chicken hanging → water bath-type hemp electricity → assassination → lek blood →hothair → hairremoval → feather water into the collection of chicken feathers → cut claw → turn hang → open → dig viscera → cutting head → carcass cleaning → pre-cooling → carcass drain → internal organs processing → carcass hanging → parting → sorting → packing weighing packaging →loading plate → quickfreezing → packing → refrigeration → sales.

Processing Technology Of Chicken Slaughter:

1.Chicken Conveying:

(1)Unloading the vehicle should be obtained from the origin of animal epidemic Prevention Supervision Authority issued by the Certificate of Conformity, and the car observation, not unusual, the goods in line with the license to unload.

(2)Will be equipped with chicken cages from the transport vehicle down, put on the chicken on the platform, a quarantine personnel on-site inspection, the test of qualified health chicken cages on the chicken coop conveyor, conveying to the chickens hanging.

(3)The chicken hanging and slaughter workshop strictly separate, the chicken hanging as far as possible design dark, to avoid strong light irradiation, resulting in chicken flapping wings excessive tension.

(4)Hanging chickens from the chicken coop holding chickens belly out of chicken, and then two chicken claw hanging in the production line of the hanger. Each person who hangs chickens can hang 800-1000 chickens per hour.

(5)Garage cages by the conveyor automatically transported into the cage washing machine for the cleaning of cages, cleaning the chicken coop through the cage oblique chute slide to the stage of unloading chickens.

2.Chicken Slaughter And Feather Removal:

(1)The chicken slaughter conveyor line mainly completed the process: chicken hanging, water bath type hemp electricity, assassination, drain blood, perm, hair removal, claw, turn hang, etc.

(2)The chicken hemp electricity usually uses the water bath type Hemp Electricity, the hemp .electricity voltage: 70-90v, the hemp electricity time: 2-3s. Or not through the MA electric process, the use of chicken after hanging through the elevated transmission line automatic transmission 1min, let the chicken calm down and then assassinate.

(3)The chicken after the assassination of the blood, draining time is generally designed for 3-4min. Hot Hair Time: 40-60s, hair removal time: 15-30s.

(4)Hot hair using thermostat hot hair machine, hot hair temperature: 58-62 ℃. Hair removal as far as possible using hanging-type hair removal, to avoid contact between the carcass and caused the infection.

(5)In 90 degrees corner design Automatic claw machine, claw machine by positioning wheel, drive, rotating blades, chicken claw cut, chicken claw and then removed by the claw-back into the collection vehicle.

3. Open The Entrails:

(1)The main process of the chicken opening and unloading of the rack is: the opening, the cutting of the viscera, the cutting head, the carcass cleaning, etc.

(2)Will take out the organs in the gut in the chute, the inspection and quarantine personnel, inspection of the chicken carcass into next working procedure, inspection of chicken processing between internal organs into the internal processing, unqualified carcass and viscera in a closed car pull in slaughtering workshop processing.

4.Precooling:

(1)Precooling of precooling and spiral precooling machine, the area of pre-cooling of the pool is larger than that of precooling machine.

(2)Precooling water temperature: 0-2 ℃, the precooling time: 45 min.

(3)The precooled carcass shall be drained by drain or elevated conveyor line.

(4)The chicken carcass center after precooling temperature under 10 ℃.

Technical Parameters:

| No. | Description | Model |

| 1 | Conveying line | GGXS152-15 |

| 2 | Main drive and tensioning device | GGDZJ-13 |

| 3 | Blood receiving trough | 5500*1400*800 |

| 4 | steam-blowing Type Immersing & scalding machine | 4500 |

| 5 | “A” shaped plucker | 4*12 |

| 6 | Shackle washer | GGQX-2 |

| 7 | Controlling cabinet | GGKG-1 |

| 8 | Automatic feet cutter | 180 |

| 9 | Automatic feet unloader | 1000*400*800 |

| 10 | Automatic head puller | GGTJ-2 |

| 11 | Viscera slide trough | 8000*800*800 |

| 12 | Carcass cleaning machine | GGQX-2 |

| 13 | Screw chiller | 6000 |

| 14 | Control cabinet for screw chiller |

Ms Alice

Sales & Marketing Director

Add : Henan Gelgoog Machinery Co.Ltd, No.100 Shangdu Road,Zhengzhou, Henan, China