- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

39000 KG

-

reactor thickness:

-

20mm

-

end product:

-

Fuel Oil Steel Carbon Back

-

running type:

-

Semi-continuous

-

cover area:

-

35M*15M*1O*

-

after sale service:

-

free engineer send to customer for installation and debugging

-

Main Parts Material:

-

Q345R. cr12 Alooy steel .stainless steel

-

machine test:

-

X-way and pressure testing

-

heating fuel:

-

pyrolysis oil .Natural gas ,coal

-

Function:

-

Extract Oil from solid waste

-

Output:

-

40-45% Fuel Oil

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUEDA

-

Equipment Capacity:

-

15-18mt/d

-

Weight (KG):

-

39000 KG

-

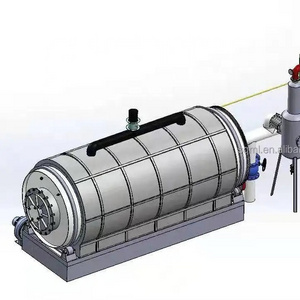

reactor thickness:

-

20mm

-

end product:

-

Fuel Oil Steel Carbon Back

-

running type:

-

Semi-continuous

-

cover area:

-

35M*15M*1O*

-

after sale service:

-

free engineer send to customer for installation and debugging

-

Main Parts Material:

-

Q345R. cr12 Alooy steel .stainless steel

-

machine test:

-

X-way and pressure testing

-

heating fuel:

-

pyrolysis oil .Natural gas ,coal

-

Function:

-

Extract Oil from solid waste

-

Output:

-

40-45% Fuel Oil

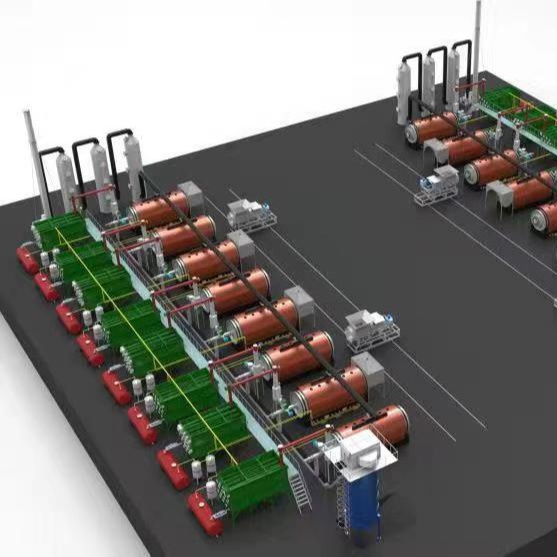

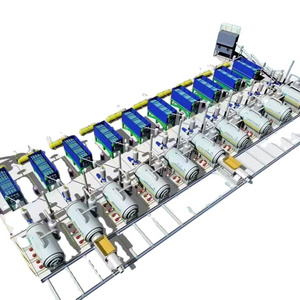

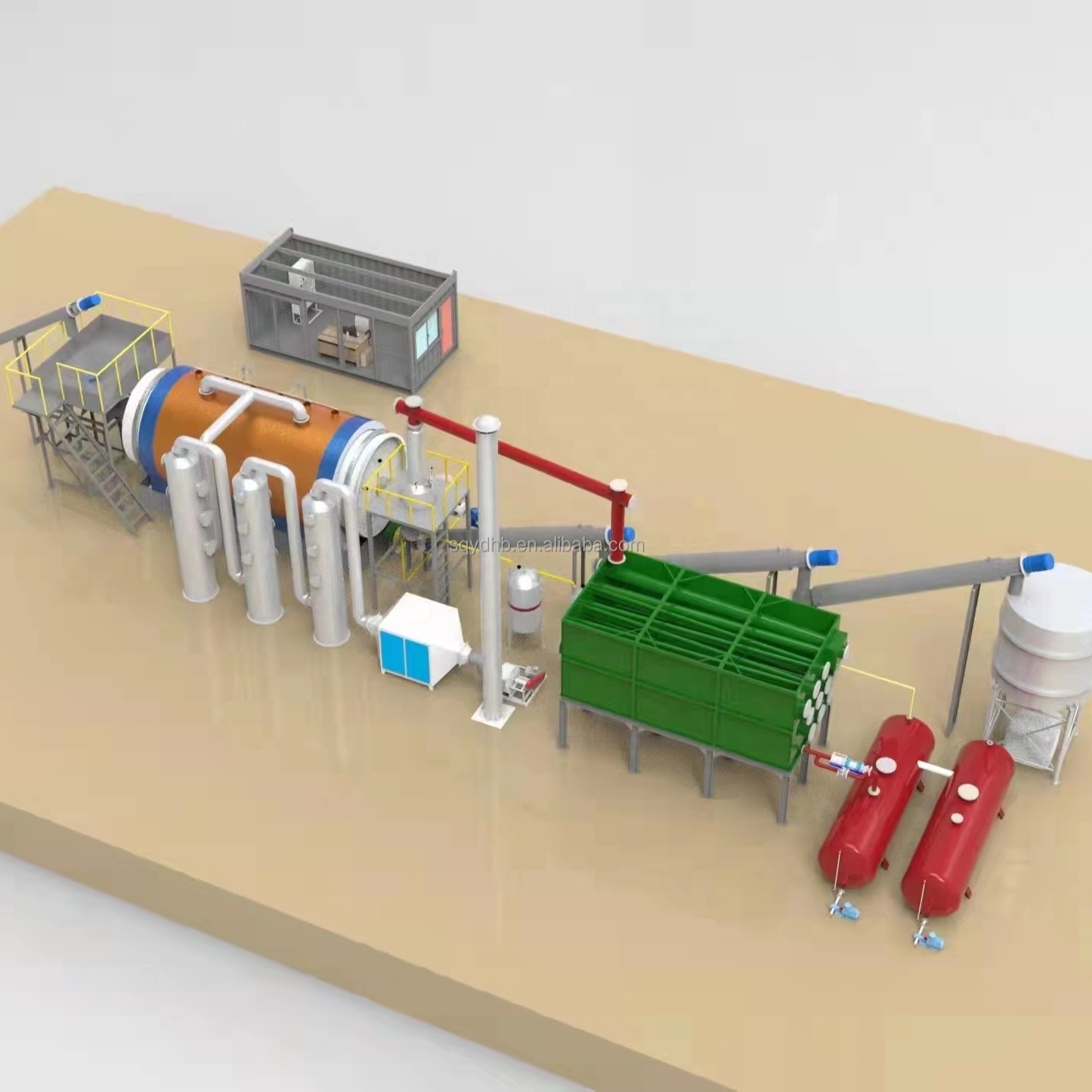

Products Description

|

waste tire oil pyrolysis plant ---

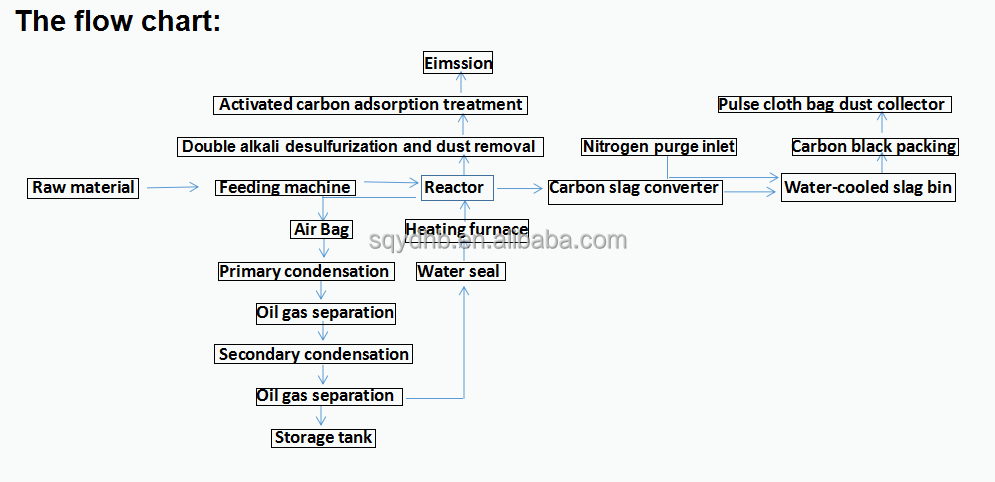

First, the raw materials are put into the reactor and seal the doors in the reactor waste tire oil pyrolysis plant --- Second, start the machine and reactor will rotating and be heated. When the inside temperature reaches the degree of 250 to 280, the oil gas will begin to generate while flow through oilgas separator, and continuously produce until the temperature up to the degree of 350 to 460. waste tire oil pyrolysis plant --- Third, in oil gas separator, light component will enter the condensers, meanwhile, heavy component will be liquefied and then automatically discharged into heavy oil tank. waste tire oil pyrolysis plant --- Forth, most of the light component will be liquefied through condensers to crude oil. Small amount of oil gas cannot be liquefied and will be transferred by water seal tank back to the burning chamber to be reused as heating fuel. Carbon black will automatically sent from taphole and steel wire will pull out. |

Why Choose Us

Shangqiu YUEDA ENVIRONMENTAL PROTECTION TECHNOLOGY Co., Ltd, as the first domestic professional institute in the recycling of solid wastes( waste plastics, waste rubber, tyres), is a technology innovate demonstration enterprise involving scientific research, development, manufacture and sales together. our company has achieved great progress in waste recycling area. Nowadays, our company has owned 14 national patents and a provincial engineering research center. And our products has achieved CE, SGS, ISO, BV, TUV certifications. The emission can meet GB13271-2001 related standards. Our company has developed yd-series environmental protection equipments with the outstanding advantages of less investment, high efficiency, simple operation, environmental friendly and so on. Up to now, our products include Pyrolysis Plants for waste rubber, plastic and tyres, normal pressure Distillation Plants for waste engine oil, crude oil and the Carbon Black Deep-process Machines.Due to the unique advantages, our machines are widely used in China and overseas, such as Poland, Austria, Albania, Turkey, Republic of Korea, Thailand, India, Africa countries, etc.

Sample Room

Production Line

Product packaging

FAQ

1.Q: What's The Raw Material Can be processed?

A: Waste Tyre, Used rubber, Waste plastic, OIl sludge, Crude heavy oil

2.Q:What's the Output after pyrolysis?

A: Fuel oil , Carbon black, waste gas

3.Q: What's the daily processing time?

A: 7-16Hours for pyrolysis time with different processing capacity

4.Q: Is there any installed machine can be visited?

A: There are many sets of installed pyrolysis plant in China and there are 2 sets plant nearby our factory. Most welcome to visit

Hot Searches