- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

Make charcoal

-

Raw material:

-

Biomass Wastes

-

Feeding moisture:

-

15%-20%

-

Feeding size:

-

10-50mm

-

Capacity:

-

5-10tons charcoal/day

-

Fuel:

-

Gas or biomass wastes

-

Advantage:

-

Continuous Working Environment Friendly

-

Key words:

-

Activated carbon rotary kiln

Quick Details

-

Place of Origin:

-

Henan, China

-

Product name:

-

Continuous activated carbon rotary sawdust carbonization furnace kiln

-

Name:

-

Activated carbon rotary kiln

-

Usage:

-

Make charcoal

-

Raw material:

-

Biomass Wastes

-

Feeding moisture:

-

15%-20%

-

Feeding size:

-

10-50mm

-

Capacity:

-

5-10tons charcoal/day

-

Fuel:

-

Gas or biomass wastes

-

Advantage:

-

Continuous Working Environment Friendly

-

Key words:

-

Activated carbon rotary kiln

Continuous activated carbon rotary sawdust carbonization furnace kiln

Brief introduction of Activated carbon rotary kiln:

Activated carbon rotary kiln is an ideal device to convert biomass powder to get natural charcoal dust under high temperature. The raw material goes through the destructive distillation process in the oxygen-free environment to reach high carbonization degree.

\

\

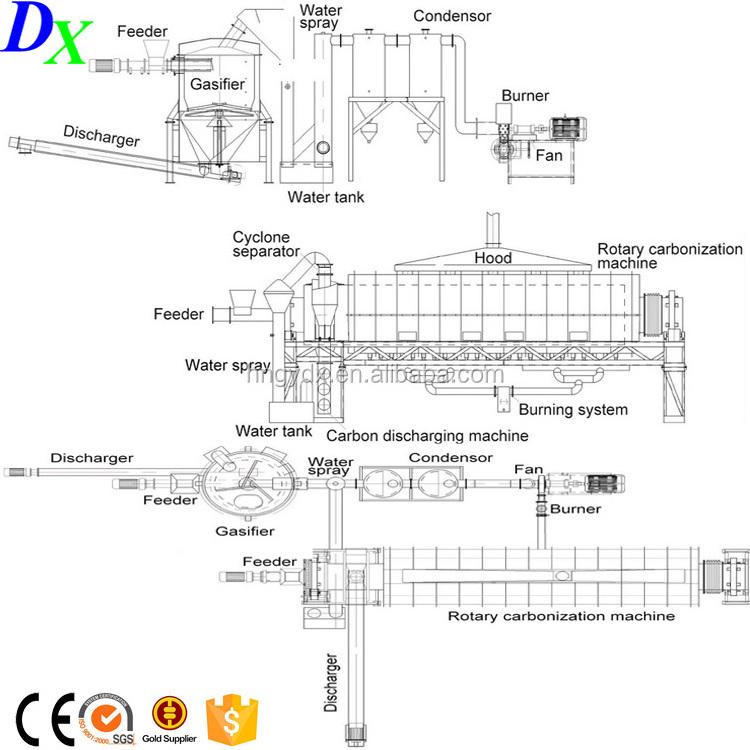

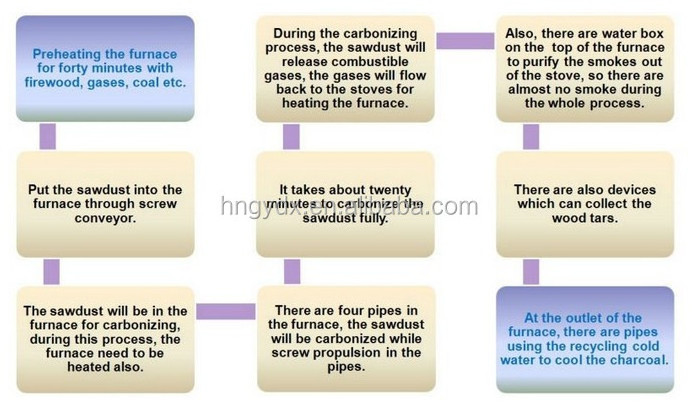

Woring Principle of Activated carbon rotary kiln:

First the biomass material is ignited in the gasifier.

The flue gas produced by burning after spraying, cooling, purification process, it produces the pure combustible gas (carbon monoxide, methane, ethane, etc.).

As the early stage of the carbonization of heat source, through early warming of the carbonizer, to feed the material when the heat reaches the special temperature.

The combustible gas that carbonation process of flue gas by spraying, cooling, purification process into burned secondary. According to this methods of circulation, sufficient to achieve a self-sufficient, then achieve the effect of energy saving.

The flue gas through purification, to reach the environment production and flue gas emissions free. Which is reached to the standards of waste gas emptying.

The temperature of carbonization reach a 600 ℃ to 900 ℃ in the process. According to the characteristics of material, the temperature can be adjusted according to the requirements.

Data of Activated carbon rotary kiln:

|

Name |

Activated carbon rotary kiln |

|

|

Model |

800*860 |

1000*10600 |

|

Capacity |

400-600kg/h |

800-1000kg/h |

|

Power |

21kw |

23kw |

|

Voltage |

380V 3phase 50HZ |

|

|

Screw conveyor |

219*5000 |

273*6000 |

|

Feeding screw |

219*2200 |

273*2200 |

|

Output conveyor |

219*5000 |

219*6000 |

|

Gasifier diameter |

1500 |

1700 |

|

Material required size |

10-50mm |

10-30mm |

|

Feeding moisture |

15-20% |

15%-20% |

|

Material and charcoal rate |

3:1 |

3:1 |

|

Required working site |

80CM2 |

80CM2 |

We can enlarge the machine size depends on your capacity. The biggest diameter is 2m because of shipping container width.

Raw material of Activated carbon rotary kiln:

(1)Almost all of the biomass straw, fruts husk and wood scraps:

Such as Sawdust,Rice Husk,Groundnut Shell,Plants Straw, Tree Bark,Grinded Coconut shell,Bamboo dust,Bagasse,Cotton Stalk,Coffee Husk,Mustard Husk/Stalk,Pine Needles,Sugar Mill Waste,Jute Waste,Coir Pith and other wastes&residues like Castor Shell,Red Gram Stalk,Tobacco Stem,Tea Waste,Sander Dust,Wild Grasses,Shrubs and Sander dust etc.

(2) The Granule size of all aboved raw material should be less than 50 mm;if more than 50mm, configure a crusher.

Final products of Activated carbon rotary kiln:

Related machines of Activated carbon rotary kiln:

After getting charcoal from this biochar retort kiln, you can shape charcoal to different shapes.

It has three models depends on the final shape: Screw extruder machine , ball press machine , and Shisha briquette machine .

The final shape: Stick shape, ball/pillow shape, round/cubic shape.

Stick shape machine

Ball shape machine

Shisha briquette machine

Customers visit us:

Package and delivery of Activated carbon rotary kiln:

We normally ship it nude(like below picture). It needs 40'GP to load.