Shipping:

BY sea,use 20'GP container or 40'HQ container or Flat rack container.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v or as request

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Process flowchart:

-

Provided

-

Plant layout drawing:

-

Provided

-

Processing capacity:

-

1-300tph up

-

Complete line equipment:

-

Provided

-

Auxiliary equipment:

-

Provided

-

Diesel generator set:

-

Provided

-

Spare parts:

-

Supply

-

Application area:

-

Alluvial chrome ore mining project

-

Environmental Impact:

-

Dont use any chemicals,very eco-friendly

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Voltage:

-

380v or as request

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Process flowchart:

-

Provided

-

Plant layout drawing:

-

Provided

-

Processing capacity:

-

1-300tph up

-

Complete line equipment:

-

Provided

-

Auxiliary equipment:

-

Provided

-

Diesel generator set:

-

Provided

-

Spare parts:

-

Supply

-

Application area:

-

Alluvial chrome ore mining project

-

Environmental Impact:

-

Dont use any chemicals,very eco-friendly

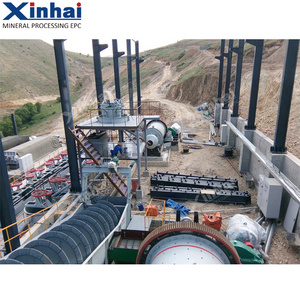

Alluvial Chrome Ore Process Plant

Regular Steps For Processing Alluvial Chrome Ore

Step 1: Washing

--trommel scrubber or trommel screen will be used in this step. If raw ore contain much sticky clay or heavy clay, need use trommel scrubber. If raw ore dont contain sticky clay,just alluvial only or just sand only, just use trommel screen.

Step 2: Classification size

--Vibrating screen or trommel screen will be used in this step.

Step 3: Gravity concentration --Spiral chute,shaker table or jig separator will be used in this step.Over 2mm chrome ore feed jig separator; less than 2mm chrome ore feed spiral chute and shaker table.

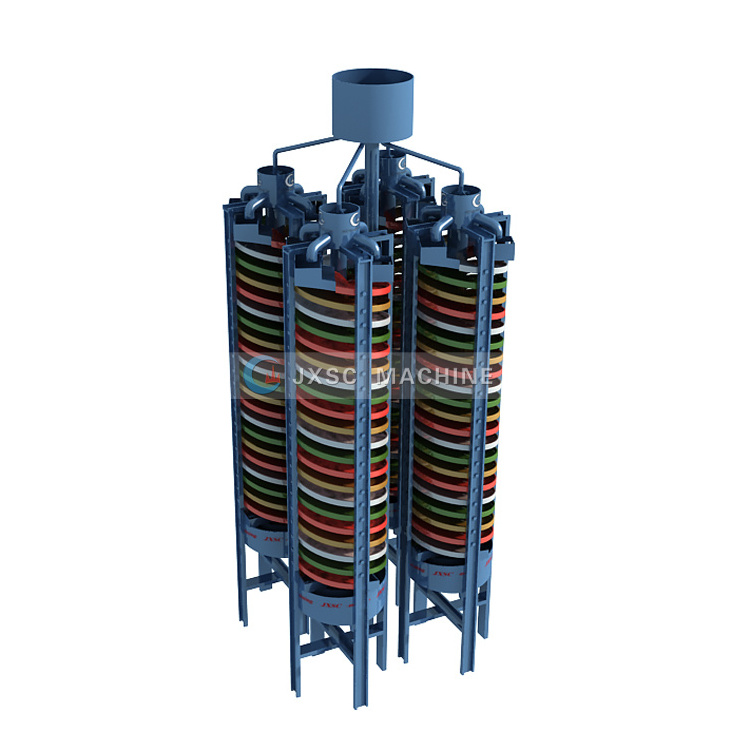

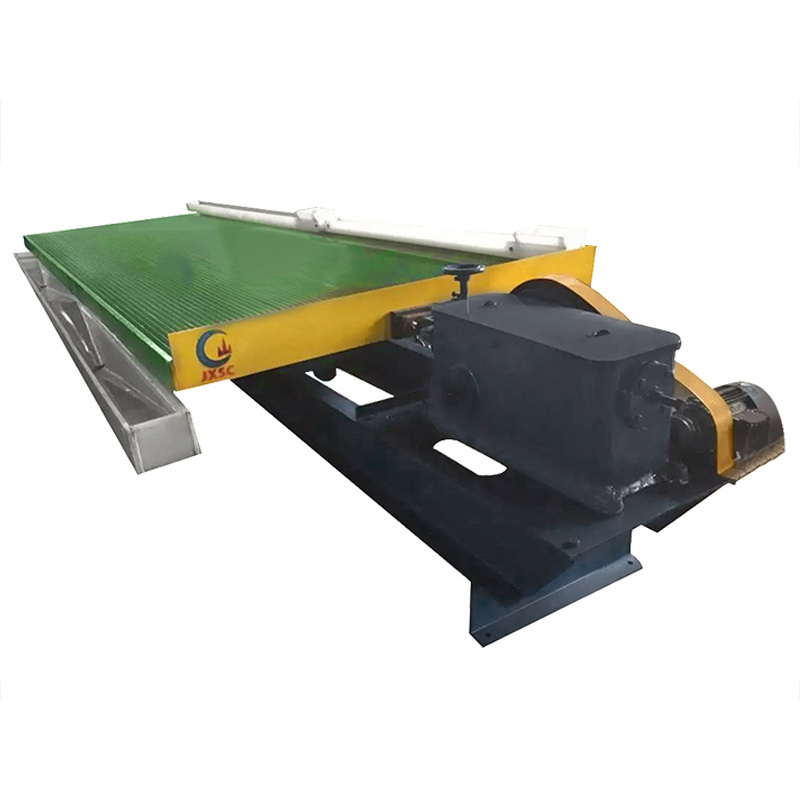

Step 3: Gravity concentration --Spiral chute,shaker table or jig separator will be used in this step.Over 2mm chrome ore feed jig separator; less than 2mm chrome ore feed spiral chute and shaker table.

Below show you the pictures of these equipment for alluvial chrome ore

Trommel Scrubber

Trommel Screen

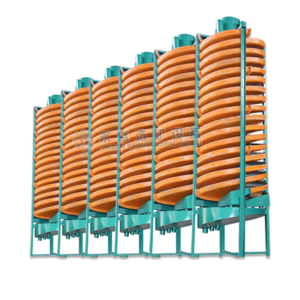

Spira Chute

Upgrade Type Big Shaker Table

Normal Type Big Shaker Table

Jig Separator

|

Model

|

Capacity (t/h)

|

Feed size (mm)

|

Outside dia(mm)

|

Maximum starts per column

|

|

5LL-400

|

0.-0.2

|

0-2

|

400

|

2

|

|

5LL-600

|

0.8-1.2

|

0-2

|

600

|

2

|

|

5LL-900

|

1.5-2

|

0-2

|

900

|

2-4

|

|

5LL-1200

|

2.5-3

|

0-2

|

1200

|

2-4

|

|

5LL-1500

|

4-6

|

0-2

|

1500

|

2-4

|

|

Model

|

Capacity (t/h)

|

Scrubber length(mm)

|

Screen length(mm)

|

Power (kw)

|

|

JXSC-400

|

0-5

|

2000

|

1200

|

3

|

|

JXSC-600

|

5-10

|

2000

|

1200

|

5

|

|

JXSC-750

|

10-20

|

2500

|

1500

|

7.5

|

|

JXSC-900

|

20-40

|

3000

|

1800

|

11

|

|

JXSC-1200

|

50-70

|

4000

|

2000

|

15

|

|

JXSC-1500

|

70-100

|

4000

|

2000

|

30

|

|

JXSC-1800

|

120-150

|

4000

|

2000

|

37

|

|

JXSC-2100

|

150-180

|

4000

|

2000

|

44

|

|

JXSC-2400

|

200-250

|

6000

|

2000

|

55

|

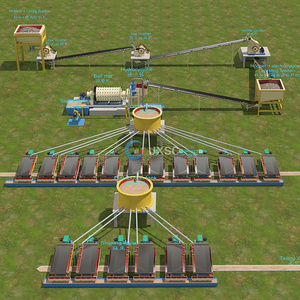

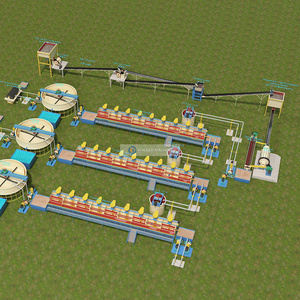

Alluvial Chrome Ore Process Flowchart

This flowchart suits for alluvial chrome ore that dont contain sticky clay. process flows as below:

1) feed vibrating screen for classification 0-3mm and 3-10mm.

2) 3-10mm feed jig separator for recovering big particles chrome.

3) 0-3mm feed spiral chute with slurry pump for recovering fine chrome.

plz note: this flowchart dont use shaker table. so the spiral chute need use two-stages separation. the middlings from first-stage spiral chute feed second-stage spiral chute for recovering fine chrome in order to increase recovery rate.

This flowchart is suitable for the alluvial chrome ore that dont contain sticky clay, also the maximum feeding size is less than 2mm.

This complete plant is configured with feeding system and spiral chute separation plant.

This flowchart suits for alluvial chrome ore that dont contain sticky clay, also the chrome concentrate size is 0-2mm.

if raw ore contain sticky clay or much clay, need use trommel scrubber instead of trommel screen.

Proceess flow as below:

1. Classification--trommel screen

2. Graivty concentration--spiral chute (two stages separation)

Packing&Shipping

Packing:

Standard parts use wooden case to pack, whole machine is directly loading on the container.

Company Introduction

Our Service

Pre-Sales Service

*Inquiry and consulting support

*Ore sample testing support

*View our Factory

*Design Flowchart

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* 1 year warranty

*

Engineers available to service machinery overseas.

FAQ

Q: Are you mining machinery manufacturer? can I visit your factory?

A: Yes, we are mining machinery manufacturer, our factory is located in Ganzhou City Jiangxi province, it has direct flight to Beijing,Shanghai,Guangzhou,Shenzhen Airport. Welcome to visit our factory!

Q:Can you produce as specific size?

A: Yes, most of our products are customized as per customer's requirements.

Q: What is the leading time?

A: For shaking table and laboratory mining equipment ,we can send out within 7 days after receiving full payment.

For large scale mining equipment and customized machine, the lead time is about 30-35 days.

Q: Do you supply oversea service?

A: Yes, we do. Engineers available to service machinery overseas.

Q: How about the warranty?

A: We will supply you one year warranty and lifelong technical support.

A: Yes, we are mining machinery manufacturer, our factory is located in Ganzhou City Jiangxi province, it has direct flight to Beijing,Shanghai,Guangzhou,Shenzhen Airport. Welcome to visit our factory!

Q:Can you produce as specific size?

A: Yes, most of our products are customized as per customer's requirements.

Q: What is the leading time?

A: For shaking table and laboratory mining equipment ,we can send out within 7 days after receiving full payment.

For large scale mining equipment and customized machine, the lead time is about 30-35 days.

Q: Do you supply oversea service?

A: Yes, we do. Engineers available to service machinery overseas.

Q: How about the warranty?

A: We will supply you one year warranty and lifelong technical support.

Q: What is the payment term?

A: 100% TT or 40% advanced payment before factory production,60% balance shall be paid before factory delivery.

Q: Do you have office abroad?

A: Yes,we have office in Tanzania. There are some regular machines in stock for sale.

JXSC Factory provide one-stop gold mining solution,diamond mining solution,coltan mining solution and turn-key service! Welcome to

inquiry!

Related Products

Hot Searches