- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hengtong

-

Dimension(L*W*H):

-

922*745*933 mm

-

Weight:

-

700 KG

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

stone crusher

-

Usage:

-

Primary Crushing

-

Max feeding size:

-

125 mm

-

Discharge size:

-

10-40 mm

-

Motor power:

-

4 Pole 5.5 kw

-

Delivery Time:

-

25-40 Days

-

Color:

-

Customer Required

-

Factory visit:

-

Welcomed Walmly

-

Wear Part:

-

Jaw Plate

Quick Details

-

Application:

-

mining used

-

Capacity(t/h):

-

2-7 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hengtong

-

Dimension(L*W*H):

-

922*745*933 mm

-

Weight:

-

700 KG

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

stone crusher

-

Usage:

-

Primary Crushing

-

Max feeding size:

-

125 mm

-

Discharge size:

-

10-40 mm

-

Motor power:

-

4 Pole 5.5 kw

-

Delivery Time:

-

25-40 Days

-

Color:

-

Customer Required

-

Factory visit:

-

Welcomed Walmly

-

Wear Part:

-

Jaw Plate

Product Description

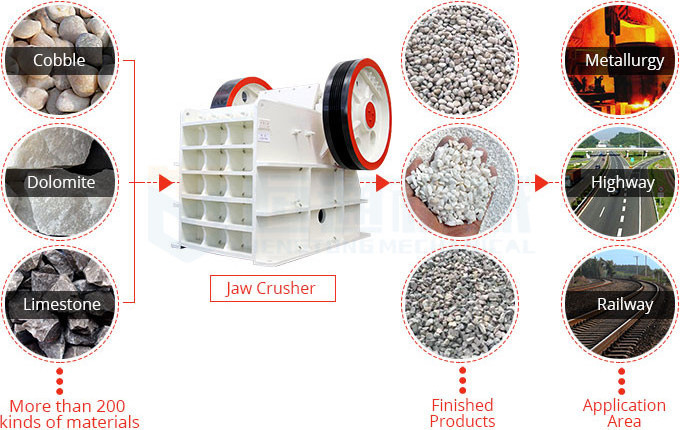

Mining small pe 150*250 mobile rock ore stone quarry quartz jaw crusher

crushing equipment price with diesel engine

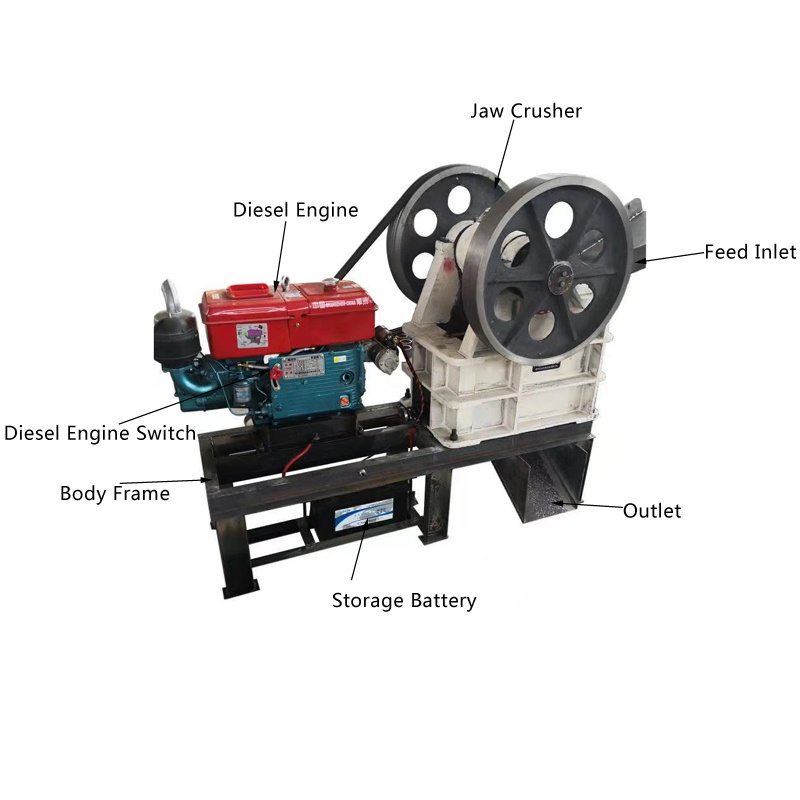

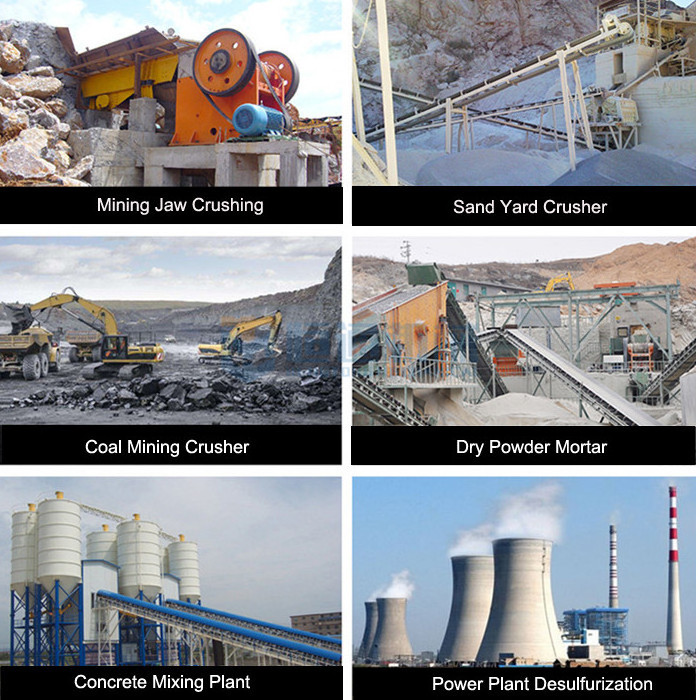

The jaw crusher is mainly composed of frame, eccentric shaft, belt groove wheel, flywheel, moving jaw, side guard plate, elbow plate, elbow plate backseat, adjusting screw, reset spring, fixed jaw plate and movable jaw plate. It has the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable work, easy maintenance, economic operating costs, etc., has become a more mature crushing machinery in the industry, and is widely used in different coal mines, metallurgy, building materials, roads, railways, water conservancy, chemical industry and many other industries around the world.

Product Advantages

Application Field

Accessories

Product Parameter

|

Model

|

Capacity (t/h)

|

Motor (KW)

|

Weight (t)

|

Dimension (L*W*H) (mm)

|

|

150*250

|

1-3

|

5.5-7.5

|

0.7

|

922*745*933

|

|

200*300

|

2-8

|

11

|

0.8

|

1056*1100*1120

|

|

250*400

|

5-20

|

15-18.5

|

3

|

1108*1142*1392

|

|

400*600

|

10-40

|

30

|

7.2

|

1700*1732*1390

|

|

350*750

|

20-50

|

37

|

8.9

|

1900*1806*1808

|

|

500*750

|

34-68

|

55

|

11.32

|

2050*1860*2145

|

|

600*900

|

40-120

|

75

|

17.6

|

2792*2168*2250

|

|

750*1060

|

80-160

|

90

|

30.53

|

4180*2560*3070

|

|

900*1200

|

110-200

|

110

|

50

|

5200*2900*3500

|

|

1000*1200

|

315-500

|

110

|

55

|

3480*2876*3330

|

|

1200*1500

|

400-800

|

160

|

100

|

4200*3300*3500

|

FAQ

1.How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

2. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

3.Do you supply training and after-sale service?

Yes, we will supply installation and training on site or online. Also we have a professional service team that can solve problems as fast as possible.

4.How do jaw crushers work?

The working part of the jaw crusher is two jaw plates, one is the static plate, which is vertically fixed on the front wall of the body, the other is the moving plate, the position is inclined, and the fixed jaw plate forms a large and small crushing chamber. The moving jaw makes periodic reciprocating movement against the static jaw. When separated, the material enters the crushing chamber and the finished product is discharged from the lower part. When it is close, the material installed between the two jaw plates is crushed by extrusion, bending and cracking.

Hot Searches