- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUNRAY

-

Year:

-

This Year

-

Voltage:

-

440V/415V/380V/220V/110V

-

Dimension(L*W*H):

-

7.2*4.3*5.5

-

Hollow part volume:

-

200

-

Screw L/D Ratio:

-

28

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

27 kW

-

Extruder Motor Power(kW):

-

55 kW

-

Mold Platen Size(Width)(mm):

-

1100 mm

-

Mold Platen Size(Height)(mm):

-

1400 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

2 m³/min

-

Die Head Heating Power(kW):

-

27 kW

-

Accumulator Capacity(L):

-

15 L

-

Power (kW):

-

140

-

Weight (T):

-

20.5

-

Model Number:

-

SUNRAY Extrusion Blow Molding Machine

-

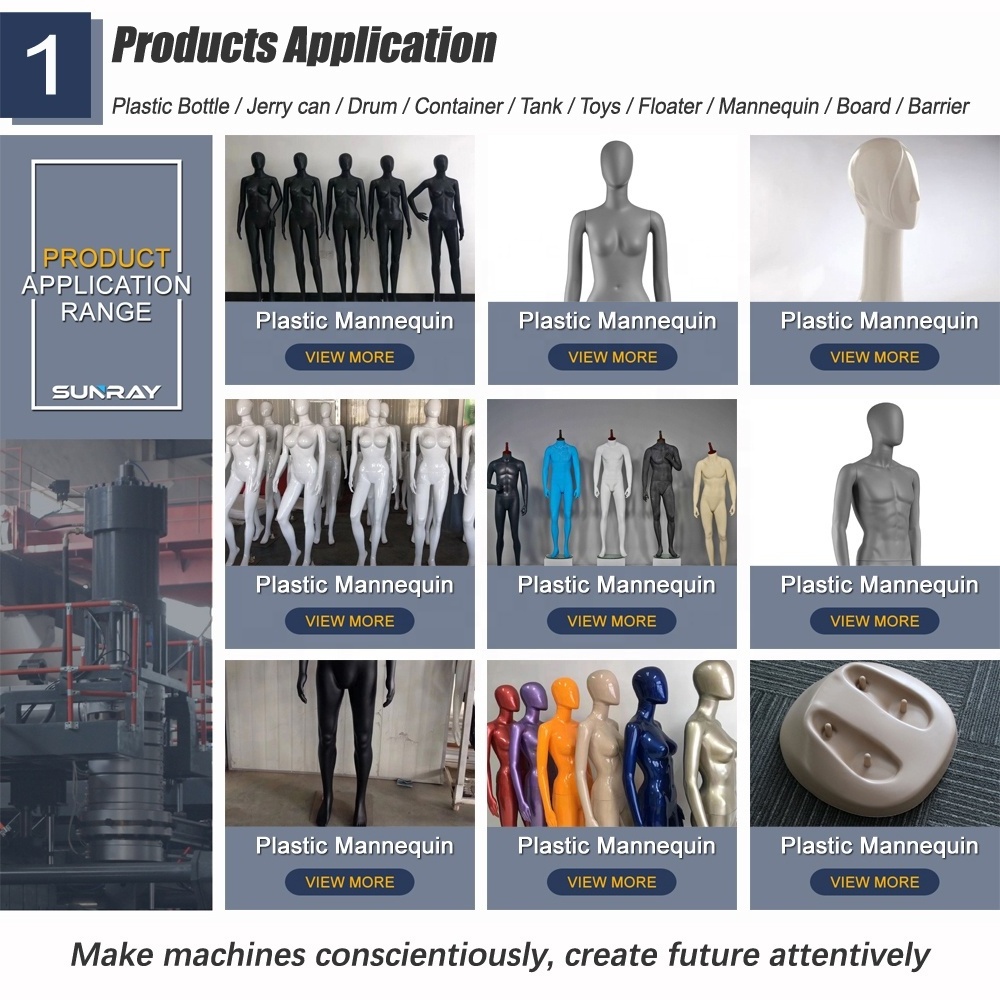

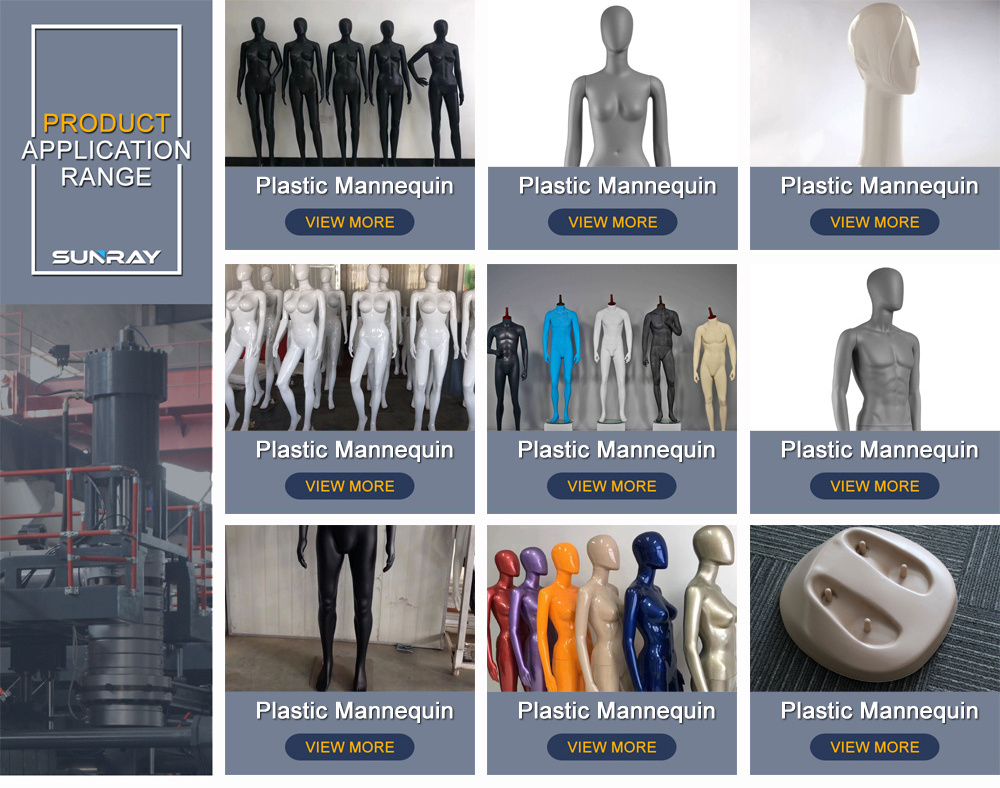

Target Product Application:

-

Mannequin

-

Project Consulation Service:

-

YES

-

OEM Production Acceptance:

-

YES

-

Whole Production Line Solution:

-

YES

-

Production Layout Assistance:

-

YES

-

Power Consumption Referenc:

-

YES

-

Freight & Loading Service:

-

YES

-

Dispatching Engineer Abroad:

-

YES

-

Operation Manual & Guidancee:

-

YES

-

Technical Support & Service:

-

YES

Quick Details

-

Clamping Force (kN):

-

700

-

Output (kg/h):

-

200 kg/h

-

Warranty of core components:

-

1 Year After Delivery

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUNRAY

-

Year:

-

This Year

-

Voltage:

-

440V/415V/380V/220V/110V

-

Dimension(L*W*H):

-

7.2*4.3*5.5

-

Hollow part volume:

-

200

-

Screw L/D Ratio:

-

28

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

27 kW

-

Extruder Motor Power(kW):

-

55 kW

-

Mold Platen Size(Width)(mm):

-

1100 mm

-

Mold Platen Size(Height)(mm):

-

1400 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

2 m³/min

-

Die Head Heating Power(kW):

-

27 kW

-

Accumulator Capacity(L):

-

15 L

-

Power (kW):

-

140

-

Weight (T):

-

20.5

-

Model Number:

-

SUNRAY Extrusion Blow Molding Machine

-

Target Product Application:

-

Mannequin

-

Project Consulation Service:

-

YES

-

OEM Production Acceptance:

-

YES

-

Whole Production Line Solution:

-

YES

-

Production Layout Assistance:

-

YES

-

Power Consumption Referenc:

-

YES

-

Freight & Loading Service:

-

YES

-

Dispatching Engineer Abroad:

-

YES

-

Operation Manual & Guidancee:

-

YES

-

Technical Support & Service:

-

YES

1. How I Can Get A Correct And Economical Project Quotation From You?

The more detailed product information you could show us, the more correct project solution plan we could make for you. Usually we need your target products' photos or design, dimension and weight are very helpful for us to calculate production capacity correctly. If you want some changes or optimization based on the sample, we also can help you to make design update according to blow-molding technics and our experience. Your requirements are welcome, deeper communication helps both you and us to know your production plan mutually, think of the solution together and achieve your goal successfully.

2. How You Can Insure Our Machines' Quality & Performance?

Our quality control starts from the beginning, rather than waiting till the machine is done.

During years' EBM machine development, details updating, practical working, customers' feedback and our improvement, our machines' design and configuration have been mature enough. In each production link and step the quality control is executing to related with our employees' assessment and income level. After your machine is finished, we will make 2-3 times commissioning and test run to make sure working performance is stable, rather than leaving the potential problems to our customers. Before delivery, we will check everything again.

3. What Preparation I Need to Make Before My Machines Arrive to Destination Port?

An adequate preparation is the good begnning of any thing, it's the important precondition also save your time.

Before delivery, we will provide production layout sketch according to your workshop, also the preparation details to list necessary tools for installation, pipe tube and joint specifications for connection, self-made assisting devices to highten working efficiency, also the engineer's working schedule and training items. We need your cooperation and feedback to synchronize our working steps, so we could dispatch engineer and compelte service jobs on time.

4. What & How I Should Do When Your Machine Got A Problem?

Machine problem isn't as terrible as human's, because machine is honest, and all the problems of machine can be solved.

Simply speaking, all problems of machine can be grouped into 2, hardware related and software related. When you found the machine stop or a problem happen to cause error, just contact us to give a problem report. We will guide you step by step to make diagnosis. The engineering pages of our control system helps to find the real reason quickly, with our on-line meeting and remote support, international and general configuration parts, routine problem could be solved on the same day.

5. Why Should I Buy Machines from You?

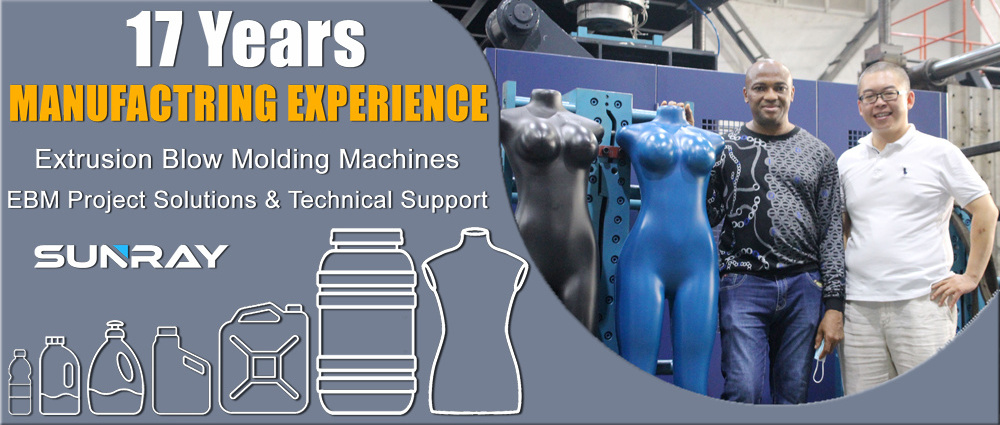

Sunray Machinery is a professional manufacturer and exporter of blow molding machines, owning many years working experience in equipment' design, manufacturing, technical support &service for whole line project solution.

|

EXPERIENCE SHARING

|

STABLE PERFORMANCE

|

DESIGN ASSISTANCE

|

TECHNICAL SUPPORT

|

PROJECT SOLUTION

|

|

We own many years working experience in blow molding field to share with you, from product design to the new project investment

|

Reasonable design, prcise processing, skilled assembly, strict quality control and test to insure stable performance

|

Sample precheck, design analysis and optimization based on blow molding production technics to solve potential troubles and risk

|

Remote monitoring, on line program updating, problems feedback, enough spare parts, good after sales service & technical support

|

Focus on your target product, production technics economical investment, working as your one stop whole line supplier

|

Hot Searches