- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

950*500*950mm

-

Weight:

-

110 KG

-

Product name:

-

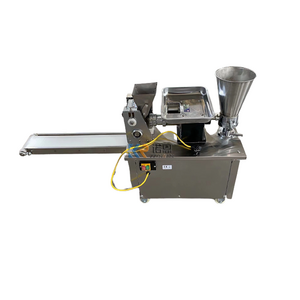

Small Price Samosa Maker Dumpling Cutter Pierogi Making Machine

-

Usage:

-

Various Dumplings

-

Feature:

-

Automatic

-

Material:

-

Stainless Steel

-

Capacity:

-

7200 Piece / Hour

-

Raw material:

-

Flour

-

Function:

-

Produce Dumpling

-

Mould:

-

Customized Moulds

-

Application:

-

Restaurants

-

dumpling shape:

-

Can be customized

Quick Details

-

Production Capacity:

-

4800pcs/h-7200pcs/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Penghui

-

Voltage:

-

220V

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

950*500*950mm

-

Weight:

-

110 KG

-

Product name:

-

Small Price Samosa Maker Dumpling Cutter Pierogi Making Machine

-

Usage:

-

Various Dumplings

-

Feature:

-

Automatic

-

Material:

-

Stainless Steel

-

Capacity:

-

7200 Piece / Hour

-

Raw material:

-

Flour

-

Function:

-

Produce Dumpling

-

Mould:

-

Customized Moulds

-

Application:

-

Restaurants

-

dumpling shape:

-

Can be customized

Product Description

Product Using

: Automatic Chinese Dumpling Making Machine is applicable to make dumpling, samosa, spring rolls and wontons by changing the forming mould. The stuffing of these finished products can be all kinds of 100% meats, all kinds of 100% vegetables and mixture of meat and vegetable, and these finished products can be boiled, steamed, fried and freezed. The thickness of dough crust and the quantity of filling can be adjusted as well.

Features:

1. Raw materials: Flour, Rice

2. Products: This machine can be used to produce dumplings, samosa, spring rolls and wontons by changing the mould.

3. Production efficiency: 4800pcs/h, 6000pcs/h

4. Operation: put the paste and the stuffing into the machine, then get the products you required

5. Voltage in China: 220V/50Hz, we can customize it according to customers' Local voltage.

6. Machines materials: All the machines are made by stainless steel, this line is with reasonable design and with high automation; waterproof electrical machine.

7.We have our own mould process workshop, are able to supply custom-made mould, that to say, we can do the shapes as your requirements.

Installation:

1.Check the power switch, mould, car boot before and skinned dumpling

Whether a foreign body in the conveyor belt.

2.Cut the dough is placed on the surface of the shelf, open the "long stop" button, point

Click the power start "switch, so that the machine in the electrifying state, click" lose face and

"Button, will be followed by the various road surface rolling roller.

Start forming die buttons, make its speed and input the dough to speed the process requirements

3.Start button mold to lose speed and surface speed of the process requirements match,then through the mold face with a dumpling shape, mold and adjust the output side Speed, and while adjusting the gap between the wheel rolling surface, so that the dough weight to the process requirements.

4.Turn on the switch of input box and adjust the speed to make dumplings single weight to work Arts requirements.

1. Raw materials: Flour, Rice

2. Products: This machine can be used to produce dumplings, samosa, spring rolls and wontons by changing the mould.

3. Production efficiency: 4800pcs/h, 6000pcs/h

4. Operation: put the paste and the stuffing into the machine, then get the products you required

5. Voltage in China: 220V/50Hz, we can customize it according to customers' Local voltage.

6. Machines materials: All the machines are made by stainless steel, this line is with reasonable design and with high automation; waterproof electrical machine.

7.We have our own mould process workshop, are able to supply custom-made mould, that to say, we can do the shapes as your requirements.

Installation:

1.Check the power switch, mould, car boot before and skinned dumpling

Whether a foreign body in the conveyor belt.

2.Cut the dough is placed on the surface of the shelf, open the "long stop" button, point

Click the power start "switch, so that the machine in the electrifying state, click" lose face and

"Button, will be followed by the various road surface rolling roller.

Start forming die buttons, make its speed and input the dough to speed the process requirements

3.Start button mold to lose speed and surface speed of the process requirements match,then through the mold face with a dumpling shape, mold and adjust the output side Speed, and while adjusting the gap between the wheel rolling surface, so that the dough weight to the process requirements.

4.Turn on the switch of input box and adjust the speed to make dumplings single weight to work Arts requirements.

Specification

|

Model

|

PH-01

|

PH-02

|

PH-03

|

PH-04

|

|

Capacity (Pcs/H)

|

4800

|

5500

|

6000

|

7200

|

|

Power ( kw /voltage)

|

2.2/220

|

2.2/220

|

2.3/220

|

2.3/220

|

|

Weight(Kg)

|

110

|

120

|

120

|

130

|

|

Dimension (cm)

|

65x45x80

|

135x45x80

|

95*50*95

|

165*50*95

|

More pictures

A variety of molds can be customized

Machine details

Dumpling shape can be customized

Size can be customized

Weight can be customized

Packing & Delivery

Package:

Standard export Wooden box packing.

Delivery time:

3-20 days after confirming order, detail delivery date should be decided according to shipping.

Standard export Wooden box packing.

Delivery time:

3-20 days after confirming order, detail delivery date should be decided according to shipping.

Hot Searches