- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

750 KG

-

Product name:

-

mini gold shaking table

-

Other name:

-

vibration shaker table

-

Keywords:

-

copper shaker table 6s

-

Application:

-

Gold

-

Installation:

-

Engineer Guide

-

Recovery rate:

-

95-98%

-

Feeding Size:

-

0.15-2mm

-

Processing capacity:

-

0.5-2t/h

-

Quality:

-

High Reputation

-

Related product:

-

wet pan mill, ball mill, jaw crusher, concentrator

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NESTOR

-

Voltage:

-

220V/380V

-

Weight:

-

750 KG

-

Product name:

-

mini gold shaking table

-

Other name:

-

vibration shaker table

-

Keywords:

-

copper shaker table 6s

-

Application:

-

Gold

-

Installation:

-

Engineer Guide

-

Recovery rate:

-

95-98%

-

Feeding Size:

-

0.15-2mm

-

Processing capacity:

-

0.5-2t/h

-

Quality:

-

High Reputation

-

Related product:

-

wet pan mill, ball mill, jaw crusher, concentrator

Products Information

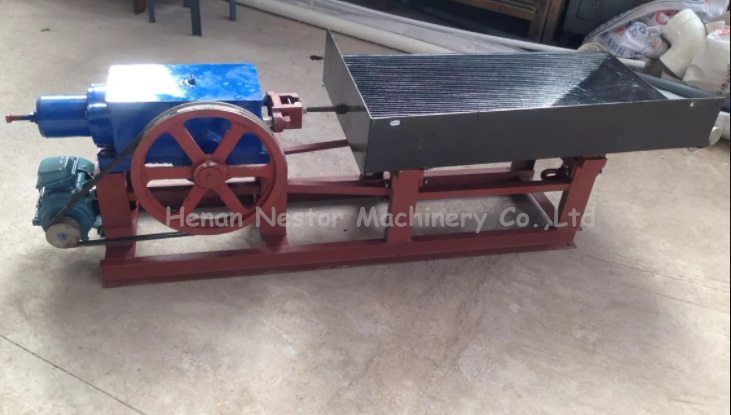

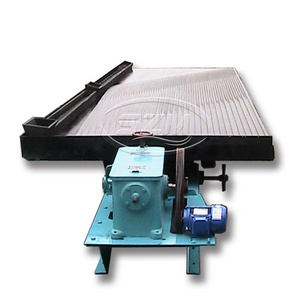

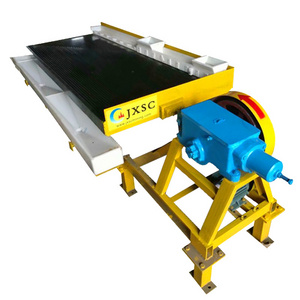

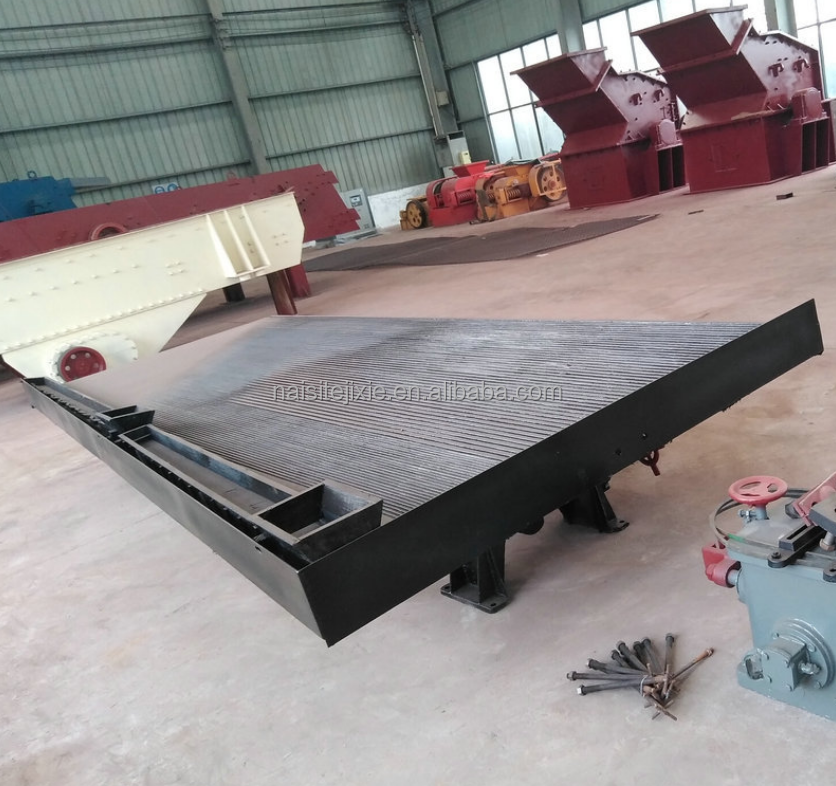

Introduction of Gold Shaker table

Shaking Table is designed to wet gravity-based separation of minerals and other granular materials. There are many applications where the concentrating table is of particular value and cannot be equaled for economical and efficient performance. They are effective in processing precious and base metal, rare metal and non-metallic minerals.

FEATURES OF GOLD SHAKER TABLE

1)

Get concentrate and gangue at one time

2) Fine water-resistance, chemical resistance, corrosion resistance, abrasion resistance, etc;

3) We can simplify the repair and painting process, which directly reduces the maintenance cost, greatly increases recovery rate, and prolongs the life of ore concentration tables.

4) High enrichment ratio, good selection effect, easy operation

5) Low energy consumption, competitive price

2) Fine water-resistance, chemical resistance, corrosion resistance, abrasion resistance, etc;

3) We can simplify the repair and painting process, which directly reduces the maintenance cost, greatly increases recovery rate, and prolongs the life of ore concentration tables.

4) High enrichment ratio, good selection effect, easy operation

5) Low energy consumption, competitive price

WORKING PRINCIPLES

Shake table is on the lean table board with raffles. The ore material is fed in by the feeding chute upper table board; meanwhile, the water is fed by water feeder transversely. Under the impact of vibrating wave, the materials go on vertical and horizontal movement as per the different proportion and granularity. The ore material with different proportion and granularity move down in ladder shipped state along with their own movement, then discharge from the fine concentrate end and tailings end, finally they are separated out to fine concentrate, middle concentrate and tailings.

PRODUCT SPECIFICATIONS

|

Model

|

Stroke (mm)

|

Cross Slope (°)

|

Feed size (mm)

|

Feed Density (%)

|

Water Consumption (t/h)

|

Capacity (t/h)

|

Power (KW)

|

Weight (KG)

|

|

6S-4450*1855*1546

|

8-22

|

1-4

|

2-0.074

|

15-30

|

0.4-1

|

0.6-1.8

|

1.1

|

800

|

|

LY-3000*1620*1360

|

6-30

|

0-10

|

2-0.074

|

10-30

|

0.3-1.5

|

0.4-1.5

|

1.1

|

550

|

|

LY-2100*1050*850

|

12-28

|

0-8

|

2-0.074

|

10-30

|

0.2-1

|

0.3-0.8

|

1.1

|

350

|

|

LY-1100*500*430

|

9-17

|

0-10

|

2-0.074

|

10-30

|

0.1-0.5

|

0.05-0.2

|

0.55

|

150

|

Customer Case

Similar Product

Hot Searches