Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V,or customized

-

Dimension(L*W*H):

-

10.2mx3.3mx4.46m

-

Weight:

-

25000

-

Material:

-

PET

-

Application:

-

Producing Clean Plastic PET Pellets

-

Function:

-

Recycle waste plastic to granules

-

Material Processed:

-

Feeding- Plasticizing -Pelletizing-Packing

-

Raw material:

-

Waste PET Rigid Flakes

-

Final product:

-

PET PP PE Granules,Pellets

-

Automaticity:

-

Full Automatic

-

Pelletizing type:

-

Strand Cutting

-

Keywords:

-

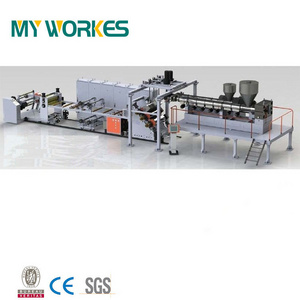

PET Plastic Granulating extruder

-

Certification:

-

CE ISO SGS

-

Marketing Type:

-

New Product 2022

Quick Details

-

Output (kg/h):

-

100 - 1200 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Acemech Machinery

-

Voltage:

-

380V/220V,or customized

-

Dimension(L*W*H):

-

10.2mx3.3mx4.46m

-

Weight:

-

25000

-

Material:

-

PET

-

Application:

-

Producing Clean Plastic PET Pellets

-

Function:

-

Recycle waste plastic to granules

-

Material Processed:

-

Feeding- Plasticizing -Pelletizing-Packing

-

Raw material:

-

Waste PET Rigid Flakes

-

Final product:

-

PET PP PE Granules,Pellets

-

Automaticity:

-

Full Automatic

-

Pelletizing type:

-

Strand Cutting

-

Keywords:

-

PET Plastic Granulating extruder

-

Certification:

-

CE ISO SGS

-

Marketing Type:

-

New Product 2022

What kind of raw materials are suitable for our machines?

What's the machines working principle?

●

Ability:

Thanks to innovative pelletizing technology and proprietary process. ACEMECH dedicated to supplying you intelligent recycling pelletizing system with superior quality which have high productivity could get high property output pellets.

●

Stability:

The pelletizing system is available for 24 hours working non-stop operation. Optimized design and top brand components to each unit. Which could minimize the downtime ratio and save the maintenance time. This ensures the maximum availability and highest productivity for user.

●

Efficiency:

The pelletizing system is designed in all details for efficiency improving. The modular design could simplify the planning and accelerate the implementation. The system have very low consumption values for electricity, water and labor. The operating costs and maintenance costs are absolutely reduced. Consistently the lowest investment costs and highest value creation.

●

Modularity:

The pelletizing system is a flexible modular system. The process required by any customer for different application could be combined freely. This design reduces planning, construction and assembly time effectively. And it's possible to adjust the system regard to technological modification and market changing. This makes the investment future-proofing.

●

Control:

Automatic control of pelletizing system reduces the labor operation, makes the whole system easier and more reliable to control, the remotes monitoring and maintenance are available for different production lines. The intelligent control has display for operating data, it also collects the data of the consumption and the capacity from production line. Which ensures the connection between the enterprises and the Internet, will improve the efficiency of enterprise management.

●

Service:

The pelletizing system is a flexible and customer-oriented recycling solution. All the components of the whole line is globally well-known brands, which ensures the reliable operation and serves your exact needs. Furthermore, Our engineers will partner with you for the whole project. Building design, overseas installation, commissioning and training are available. Machine warranty with spares in stocking and in-time delivery. Consistently quick and careful service in pre-sales and after-sales process.

|

Type

|

Capacity

(kg/h)

|

Motor power

(kw)

|

L/D

|

Rotary speed

(rpm)

|

Vacuum pump

(kw)

|

Drier

(kw)

|

|

TSK-65

|

150-350

|

45-55

|

36-40

|

300-400

|

7.5-11

|

35

|

|

TSK-75

|

250-450

|

110-132

|

36-40

|

300-400

|

11-18.5

|

58

|

|

TSK-95

|

300-1000

|

200-315

|

36-40

|

300-400

|

20-30

|

75

|