- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2021

Quick Details

-

Place of Origin:

-

GUA

-

Brand Name:

-

Argotec

-

Weight (KG):

-

95

-

Marketing Type:

-

New Product 2021

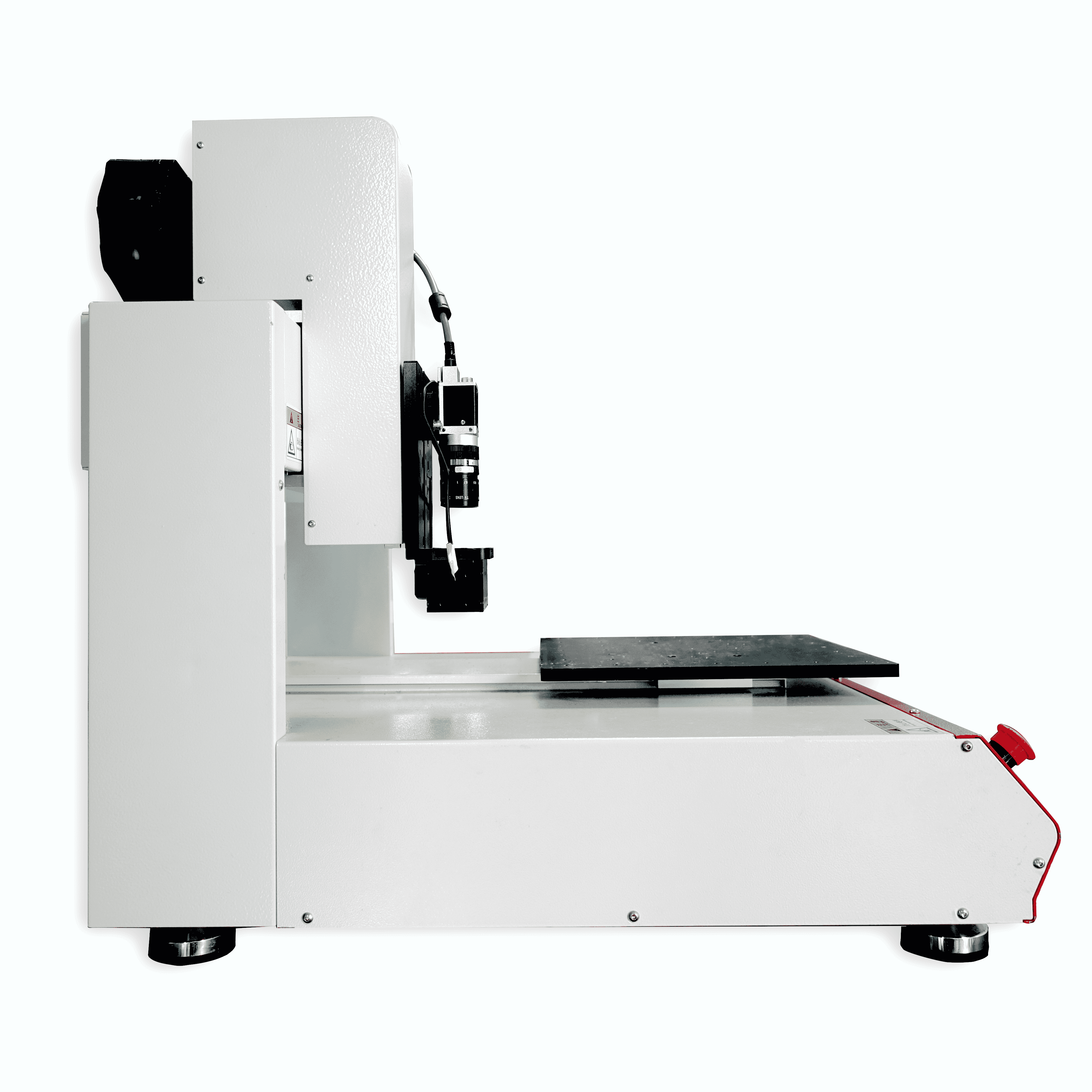

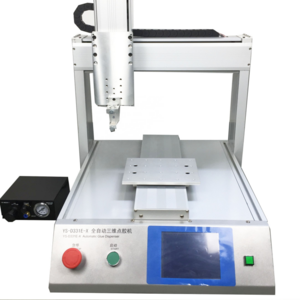

AR-SC series desktop dispensing robot adopts precision ball screw module and servo motor drive technology, and cooperates with powerful visual recognition dispensing software to realize high-speed and precise dispensing process.

Features

● Powerful visual Functions

◆Template matching

◆Edge recognition

◆Multiple sets of auxiliary mark programming

◆1.3 Mpixels camera

● High-precision motion control

◆Servo motor

◆High-precision ball screw module

● Optional functions

◆Laser height sensor

◆Needle position calibration

◆Low liquid level detector

◆Nozzle cleaner

● Powerful visual Functions

◆Template matching

◆Edge recognition

◆Multiple sets of auxiliary mark programming

◆1.3 Mpixels camera

● High-precision motion control

◆Servo motor

◆High-precision ball screw module

● Optional functions

◆Laser height sensor

◆Needle position calibration

◆Low liquid level detector

◆Nozzle cleaner

|

Specification

|

|

AR-300SC

|

AR-400SC

|

AR-500SC

|

|||

|

Effective travel

|

X

|

255mm

|

355mm

|

455mm

|

|||

|

|

Y

|

300mm

|

400mm

|

500mm

|

|||

|

|

Z

|

80mm

|

80mm

|

80mm

|

|||

|

Transmission mode

|

|

Servo motor & Ball screw

|

Ball screw

|

Ball screw

|

|||

|

Max. speed

|

|

X/Y:600 mm/s;Z:500 mm/s

|

X/Y:600 mm/s; Z:500 mm/s

|

X/Y:600 mm/s; Z:500 mm/s

|

|||

|

Position repeatability

|

|

±0.01mm

|

±0.01 mm

|

±0.01 mm

|

|||

|

Payload

|

|

Z:5kg;Workbench:15kg

|

Z:5kg,Y:15kg

|

Z:5kg,Y:15kg

|

|||

|

Control System

|

|

PC

|

Tablet

|

Tablet

|

|||

|

Software function

|

|

Visual positioning and inspection, batch modification, array copy, automatic fillet, height detection, CAD import, Jet on the fly

|

|

|

|||

|

Power

|

|

AC220V(±10%) / 50HZ / 800W

|

|

|

|||

|

Size(Without PC)

|

L

|

573mm

|

673mm

|

773mm

|

|||

|

|

W

|

578mm

|

678mm

|

778mm

|

|||

|

|

H

|

592mm

|

592mm

|

592mm

|

|||

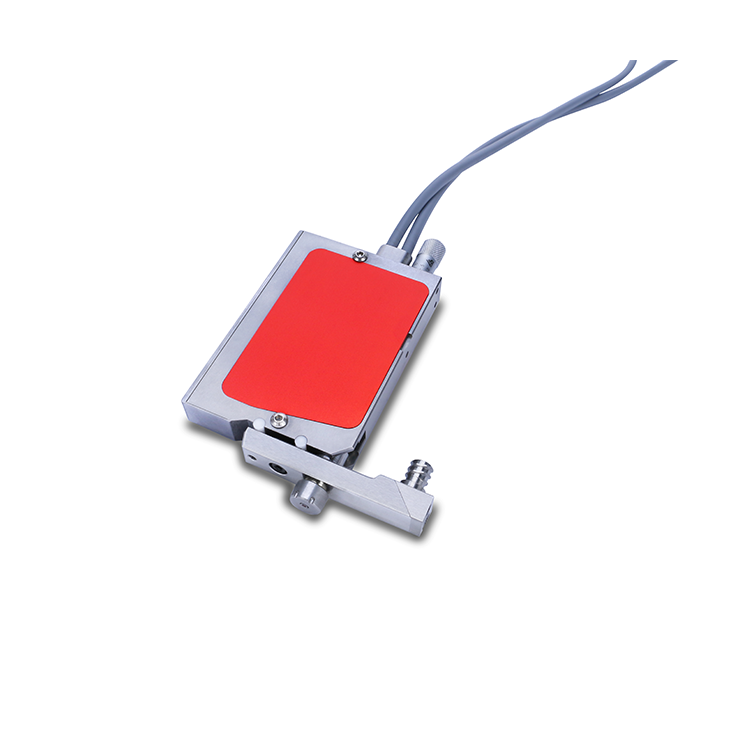

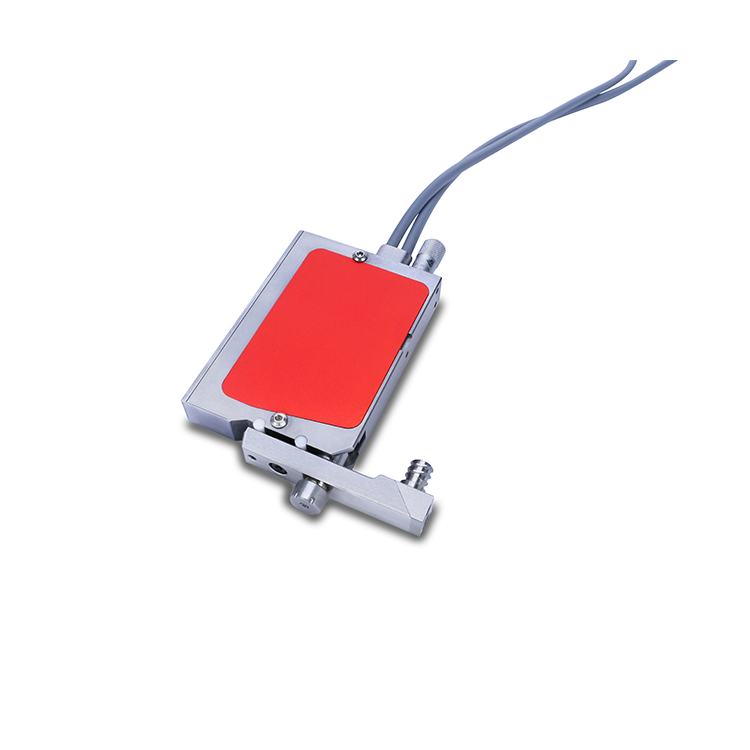

The AV-8500 piezoelectric jet valve is a device that can realize high-frequency non-contact dispensing. It is suitable for epoxy, UV, silicone, acrylic, conductive adhesive, tuffy glue and other common glue dispensing applications. It is applicable to applications requiring high-speed or non-contact gluing, such as PCBA, under-fill, sealing of components, CCM, VCM assembly, LED, semi-conductor packaging, lubricating and life technology fields. The opening and closing of the valve is controlled by piezoelectric ceramics, which has higher control accuracy and higher limit frequency. The initial position of the AV-8500 needle can be adjusted by the differential head, which can effectively compensate for changes in the stroke caused by wear.Can be used with controller AJC-56.

|

AV-8500

|

|

|

||

|

No.

|

Item

|

Data

|

||

|

1

|

Dimensions (LxDxH)

|

110mmx90mmx14mm

|

||

|

2

|

Net weight

|

0.55kg

|

||

|

3

|

The highest dispensing speed

|

500 points/sec

|

||

|

4

|

Minimum dispensing diameter

|

150μm

|

||

|

5

|

Nozzle diameter

|

0.05mm ~0.3mm

|

||

|

6

|

Feed air pressure

|

Max.0.5Mpa

|

||

|

AJC-56

|

|

|

||

|

1

|

Dimensions (LxDxH)

|

288mmx148mmx138mm

|

||

|

2

|

Net weight

|

2.3kg

|

||

|

3

|

Input power

|

220V±10%/50HZ

|

||

|

4

|

Minimum valve opening/closing time

|

0.1ms

|

||

|

5

|

Minimum rise/fall time

|

0.1ms

|

||

|

6

|

Trigger input

|

24V pulse or short circuit signal

|

||

|

7

|

Communication interface

|

RS232

|

||

Typical applications

●

VCM

● Lens Fixing

● Lens Holder Adhesive Dispensing

● Flip-chip Underfill for Image Sensor

◆ Fingerprint recognition

● IC encapsulation

● Chip underfill

● Metal frame bonding

◆ Smart phone assembly

● Sealing for Cover Frame

● Chip Encapsulation and Underfill for FPC Assembly

◆ Acoustics Devices

● Ear Phone, Speaker and Microphone Assembly

● Speaker Frame and Membrane Assembly

● Coil Assembly

◆ MEMS

● Au Wire Encapsulation

● Solder Paste Acoustical Seal

◆ Vibration Motor

● Lids sealing

● Weld pad protection

● Lens Fixing

● Lens Holder Adhesive Dispensing

● Flip-chip Underfill for Image Sensor

◆ Fingerprint recognition

● IC encapsulation

● Chip underfill

● Metal frame bonding

◆ Smart phone assembly

● Sealing for Cover Frame

● Chip Encapsulation and Underfill for FPC Assembly

◆ Acoustics Devices

● Ear Phone, Speaker and Microphone Assembly

● Speaker Frame and Membrane Assembly

● Coil Assembly

◆ MEMS

● Au Wire Encapsulation

● Solder Paste Acoustical Seal

◆ Vibration Motor

● Lids sealing

● Weld pad protection

Hot Searches