- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LONGHUA MACHINERY

-

Model Number:

-

SDD-B-R

-

Voltage:

-

3-phase 380V

-

Dimension(L*W*H):

-

MAX 6.4m(L)*2.2m(W)*1.7m(H)

-

Weight:

-

2000KG-2600KG

-

Warranty:

-

One Year

-

Product name:

-

Automatic Side Sealing Continuing Bag Making Machine

-

Application:

-

Color printed bags or blank bags like PE, PP, OPP and CPP.

-

Feature:

-

with motion controller + PLC center control system and touch screen

-

BAG WIDTH:

-

100-700mm

-

Function:

-

Side Sealing Bag Making Machine

-

Options:

-

ultrasound film pressure assembly, hole-punchers etc

-

conveyor assembly:

-

conveyor assembly

-

Servo Motor:

-

Japan

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, Viet Nam, Indonesia, Pakistan, Nigeria

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LONGHUA MACHINERY

-

Model Number:

-

SDD-B-R

-

Voltage:

-

3-phase 380V

-

Dimension(L*W*H):

-

MAX 6.4m(L)*2.2m(W)*1.7m(H)

-

Weight:

-

2000KG-2600KG

-

Warranty:

-

One Year

-

Product name:

-

Automatic Side Sealing Continuing Bag Making Machine

-

Application:

-

Color printed bags or blank bags like PE, PP, OPP and CPP.

-

Feature:

-

with motion controller + PLC center control system and touch screen

-

BAG WIDTH:

-

100-700mm

-

Function:

-

Side Sealing Bag Making Machine

-

Options:

-

ultrasound film pressure assembly, hole-punchers etc

-

conveyor assembly:

-

conveyor assembly

-

Servo Motor:

-

Japan

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, Viet Nam, Indonesia, Pakistan, Nigeria

-

Certification:

-

CE

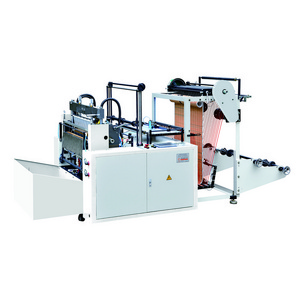

Automatic Side Sealing Continuing Bag Making Machine, SDD-B-R

1.For making hot-sealing hot-cutting side -sealing color printed bags or blank bags like PE, PP, OPP and CPP.

2.The unreeling adopts horizontal auto guide system (E.P.C), with auto unreeling tension.

3.Back feeding adopts inverter motor, swing bar angle auto-controlled by sensor, auto adaptation to machine production speed.

4.High-speed motion controller + PLC center control system and touch screen are used for clear display and easy operation.

5.Hot sea ling bar transmission adopts servo motor driving, hot-sealing duration precisely adjusted in ms. The pneumatic high-position stop structure of the new design hot sealing bar avoids heat radiation deform of the film when the machine stops running, which provides a safe operation environment.

6.The hot sealing bar is made of special tooling steel, not easy to be deformed or become adhesive, with elastic connection structure that decreases deform of hot-sealing bar significantly.

7.The conveyor assembly adopts Swiss convey belt and inversion motor for aped-adjustment. The waving-making assembly driven by servo motor, for auto adaptation to the conveyor and the wave-making aped, as well as steady outfeeding.

8.The machine has an auto bag-collection device for tidy stacking of bags.

Options:

1. ultrasound film pressure assembly

2. BOPP film assembly

3. insertion assembly

4. dual unreeling assembly

5. various hole-punchers

|

Specification |

SDD-B-500R |

SDD-B-600R |

SDD-B-700R |

|

Bag Width |

100-600mm |

100-600mm | 120-700mm |

|

Bag length |

150-480mm | 200-580mm | 250-680mm |

|

Machine Speed |

50-250pcs/min | 50-250pcs/min | 50-220pcs/min |

|

Thickness of Bag |

0.03-0.3mm | 0.03-0.3mm | 0.03-0.3mm |

|

Feeding Speed |

80m/min | 80m/min | 80m/min |

| Power Required | 7.5kw | 8kw | 9kw |

| N.W | 2000kg | 2300kg | 2600kg |

| Machine Size | 6.2x2x1.5m | 6.3 x 2 x 1.6m | 6.4 x 2.2 x 1.7m |

|

Main Features |

Brand |

Country |

|

Touch Screen |

PROFACE |

Japan |

|

PLC |

OMRON | Japan |

|

Servo Motor |

PANASONIC/ YASKAWA | Japan |

|

Motor

|

SEW | Germany |

| LIMING | Taiwan | |

|

Inverter |

FUJI/ MITSUBISHI | Japan |

|

Mark Sensor |

SICK | Germany |

| DATALOGIC | Italy | |

|

SSR |

CRYDOM | USA |

|

Pneumatic Components |

FESTO | Germany |

| SMC | Japan |