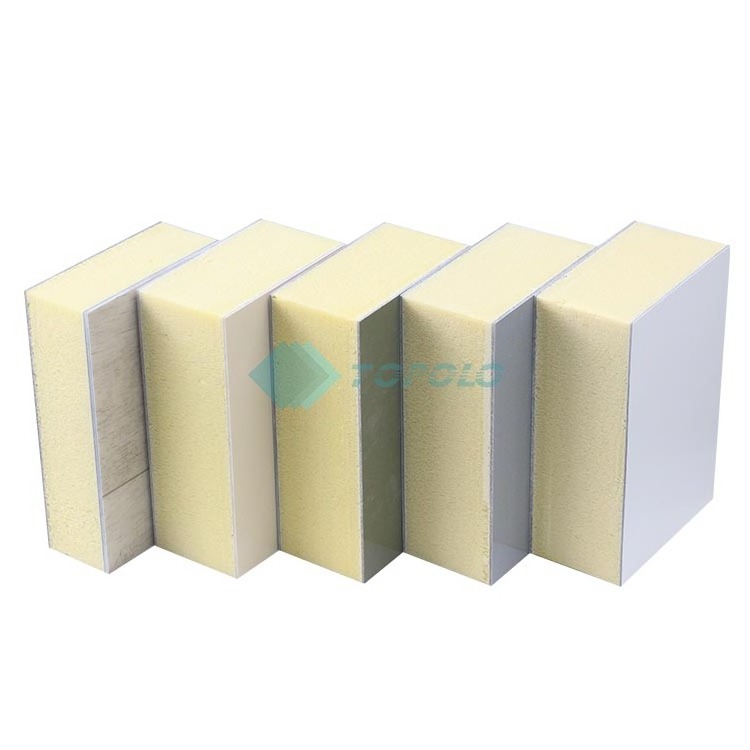

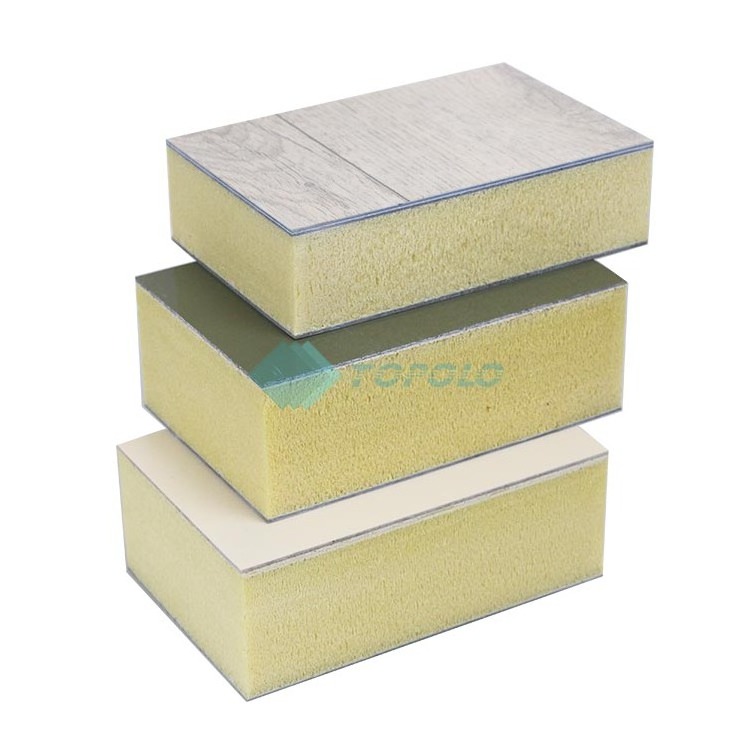

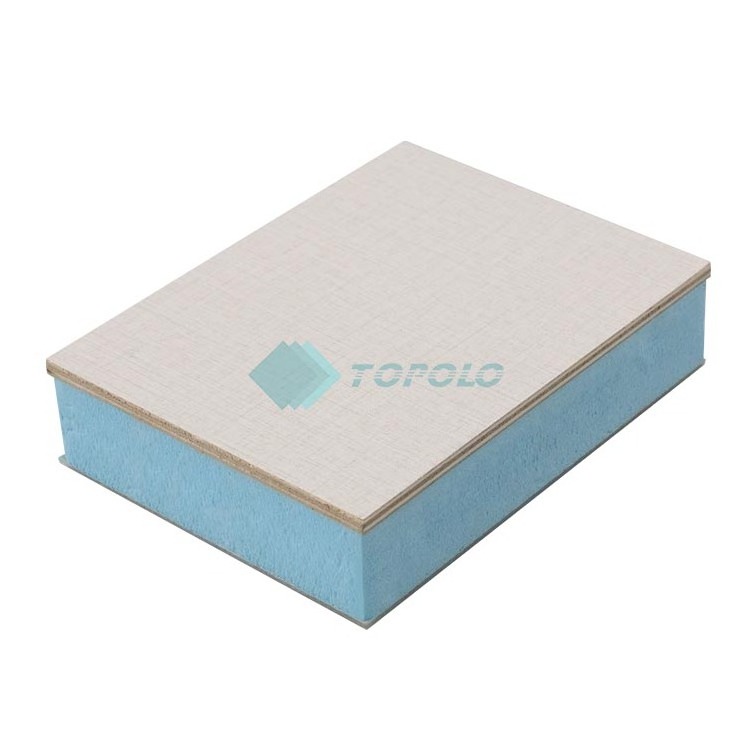

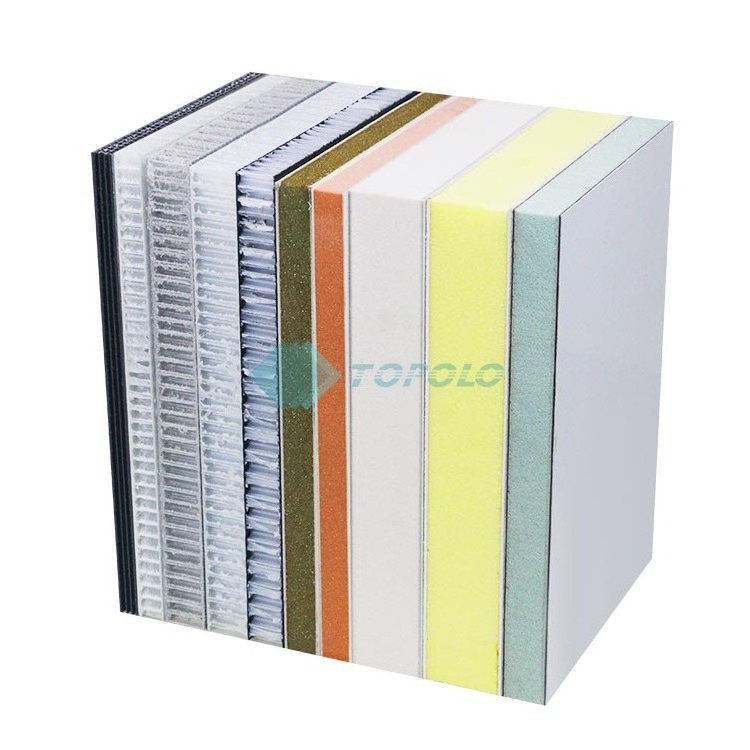

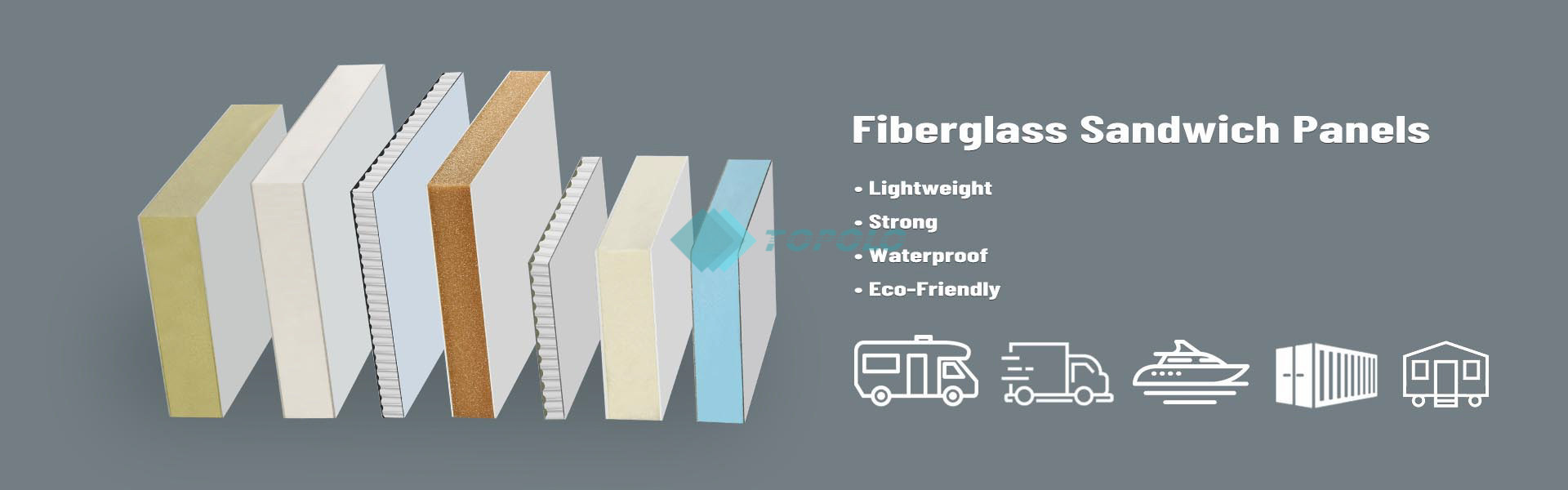

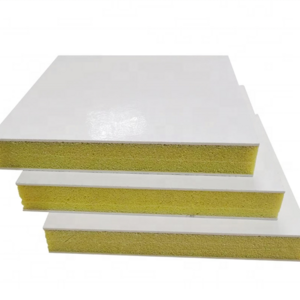

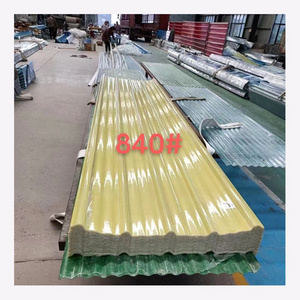

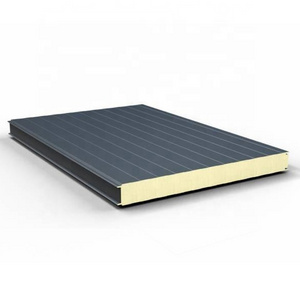

FRP sandwich panel is a new type of composite material, which contains fiberglass skin and core materials of various structures

(mostly foam board, honeycomb, and plywood). The multi-layer composite structure makes the fiberglass composite panels lighter,

stronger and more resilient. It has replaced traditional wood and metal composite panels in many fields.