- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/440V can customized

-

Dimension(L*W*H):

-

18m*5m*3m

-

Power (kW):

-

75

-

Weight:

-

4

-

Screw Speed (rpm):

-

400 - 500 rpm

-

Name:

-

plastic pelletizing granulator machine

-

Application:

-

Waste Plastic Recycling

-

Raw material:

-

PET

-

Machine:

-

Plastic pelletizing line

-

Color:

-

Customized

-

Material Process:

-

Waste PET bottle and Film

-

Motor:

-

SIEMENS/WNM

-

Contactor:

-

Schneider/Siemens

-

Inverter:

-

ABB Brand

-

Temperature controller:

-

OMRON/RKC

Quick Details

-

Output (kg/h):

-

80 - 1000 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Camel

-

Voltage:

-

220V/380V/415V/440V can customized

-

Dimension(L*W*H):

-

18m*5m*3m

-

Power (kW):

-

75

-

Weight:

-

4

-

Screw Speed (rpm):

-

400 - 500 rpm

-

Name:

-

plastic pelletizing granulator machine

-

Application:

-

Waste Plastic Recycling

-

Raw material:

-

PET

-

Machine:

-

Plastic pelletizing line

-

Color:

-

Customized

-

Material Process:

-

Waste PET bottle and Film

-

Motor:

-

SIEMENS/WNM

-

Contactor:

-

Schneider/Siemens

-

Inverter:

-

ABB Brand

-

Temperature controller:

-

OMRON/RKC

Products Description

PET Flakes Pelletizing Line

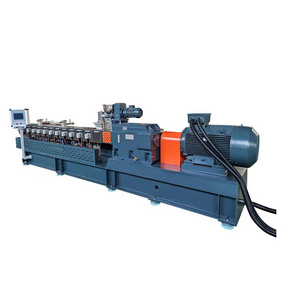

Parallel co-rotating twin screw extruder

1. The screw and barrel adopt a "building block" structure, which has good interchangeability, and can be used in any combination according to different material. The barrel material is wear-resistant, corrosion-resistant and has a long service life.

2. It adopts computer-aided design and coordination. The unique processing technology ensures the normal tooth surface clearance of the threaded working section and has good self-cleaning.

3. The specially designed connection method and transmission device enhance the strength of the threaded element and the mandrel. The above measures realize the uniform dispersion of the material and the mixing. The purpose of refining and plasticizing is good, material retention time is short, and conveying efficiency is high.

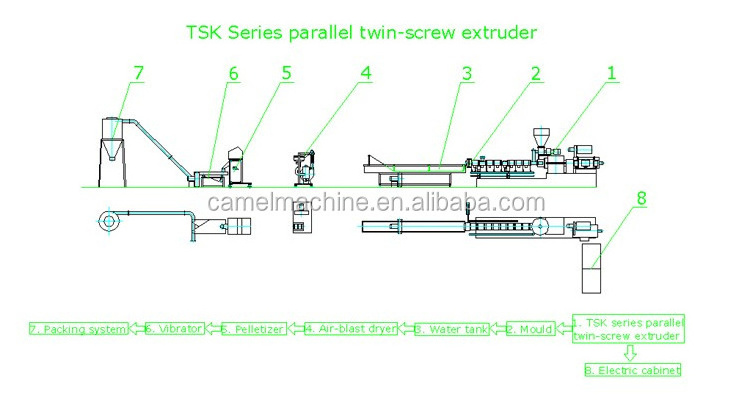

Flow Chart

Details Images

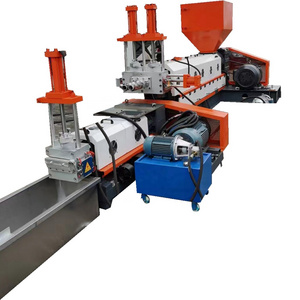

Screw feeder

PET dryer

Screen changer

Mold

Water tank

Air dryer

Pelletizer

Vibrator

silo

Technical parameter

Delivery Ways

Recommend Products

Hot Searches