- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

metal industry

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lanshuo

-

Dimension(L*W*H):

-

600*480*1360mm, 800*500*580mm

-

Weight:

-

185 KG

-

Material:

-

copper

-

Product name:

-

high frequency induction heating machine

-

Heating element:

-

IGBT

-

Usage:

-

induction heating

-

Application:

-

steel bar plate strip tube heating, hot forging

-

Feature:

-

high efficiency, energy saving, little waste

-

Input current:

-

130A

-

Oscillation frequency:

-

15--25KHz

-

cooling water flow(host):

-

29L/min(0.1mpa)

-

continuous load rate:

-

100%

Quick Details

-

Type:

-

induction heater

-

Power Source:

-

Electric

-

Voltage:

-

3-phase 380V

-

Applicable Industries:

-

metal industry

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lanshuo

-

Dimension(L*W*H):

-

600*480*1360mm, 800*500*580mm

-

Weight:

-

185 KG

-

Material:

-

copper

-

Product name:

-

high frequency induction heating machine

-

Heating element:

-

IGBT

-

Usage:

-

induction heating

-

Application:

-

steel bar plate strip tube heating, hot forging

-

Feature:

-

high efficiency, energy saving, little waste

-

Input current:

-

130A

-

Oscillation frequency:

-

15--25KHz

-

cooling water flow(host):

-

29L/min(0.1mpa)

-

continuous load rate:

-

100%

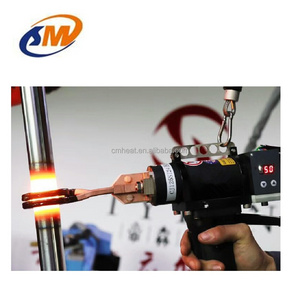

1. Brief introduction of high frequency induction heating machine

Our high frequency induction heating machine adopts IGBT series and parallel induction heating technology as the core. The induction heating machine heats the work piece to a certain temperature, and then cools it rapidly to change its machine structure to achieve some special mechanic properties.

2. Applications of high frequency induction heating machine

(1) Heat treatment: metal heating, quenching, annealing, tempering partly or wholly;

(2) Thermoforming: metal forging, hot forging, hot rolling partly or wholly;

(3) Welding: cutter blade, serrated blade, alloy cutter, steel tube, copper tube, dissimilar metal welding or brazing;

(4) Melting: gold, silver, copper, iron, aluminum and other metals melting, cast molding and evaporation coating.

3. Features of high frequency induction heating machine

( 1) High efficiency: Metal can be heated to its desired temperature, even its melting point, instantly.

(2) Energy saving: The induction heating machine adopts IGBT from Siemens & LC series circuit design, saving energy up to 15%-30%.

(3) Low cost: The heating time is short, compared to other heating methods, significantly reducing the amount of metal loss.

(4)

Easy for installation:

Following the user manual, even non-professional persons can install the induction heating machine easily.

(5)

No harm to the environment:

The induction heating machine uses electricity, producing little waste gas and water.

(6) High degree of automation: The induction heating machine can be connected with upper computer and IPC to mak e the machine operate automatically.

4. Main technical parameters of LSW-80 induction heating machine

|

LSW-80 |

|

|

Power |

80kw |

|

Input current |

130A |

|

Voltage |

3-phase 380V, 50/60Hz or customized |

|

Oscillation frequency |

18~25KHz |

|

Duty cycle |

100% |

|

Power supply cabinet dimension |

600*480*1360mm |

|

Transformer cabinet dimension |

800*500*580mm |

|

Gross weight |

185kg |

1. Pack the induction heating machine with wrapping film for waterproof;

2. Put it into a standard exporting plywood or wooden case;

3. Put foam around it for shockproof;

4. Fasten the case with nails.

As for shipping:

1. If you have a shipper in China, we can send the induction heating machine to him or her for free.

2. If you want us to send the induction heating machine to you directly , we can send it to any main port of China promptly.

1. Immediate reply to your inquiry.

2. Experienced sales answer all questions in fluent English.

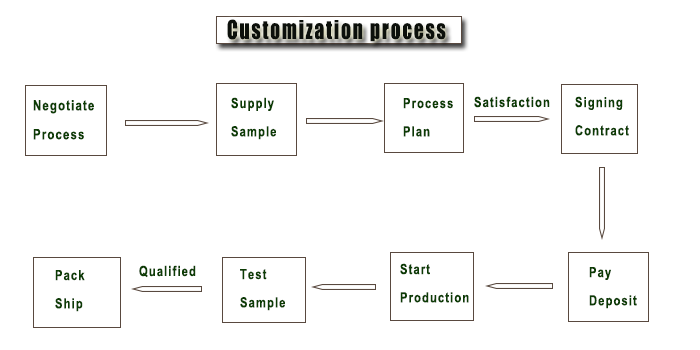

3. Customized design is available.

4. Detailed information of our products, and our company if needed.

After-sale service:

1. Technical support, or alternative accessories if necessary.

2. Freely guide installation, commissioning and test run.

3. One year’s warranty. Once there is a trouble within one year, professional engineers and sales will be promptly appointed to help.