- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

G.weike

-

Weight (KG):

-

6000 KG

-

Core Components:

-

laser source

-

Configuration:

-

ipg laser source

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Laser tube:

-

Racuys or IPG

-

Fiber laser power:

-

500W, 750W, 1000W 2000w 3000w Racuys or IPG (Optional)

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Max speed:

-

100m/min

-

X, Y and Z axis stroke:

-

3025mm, 1525mm, 100mm

-

Max acceleration:

-

1G

-

Max load-bearing of work table:

-

500KG

-

Appearance size:

-

4800*2600*1750mm

-

Working area:

-

1500mmX3000mm

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

25m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1500*3000mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

G.weike

-

Weight (KG):

-

6000 KG

-

Core Components:

-

laser source

-

Configuration:

-

ipg laser source

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Laser tube:

-

Racuys or IPG

-

Fiber laser power:

-

500W, 750W, 1000W 2000w 3000w Racuys or IPG (Optional)

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Max speed:

-

100m/min

-

X, Y and Z axis stroke:

-

3025mm, 1525mm, 100mm

-

Max acceleration:

-

1G

-

Max load-bearing of work table:

-

500KG

-

Appearance size:

-

4800*2600*1750mm

-

Working area:

-

1500mmX3000mm

hot sale Gweike LF3015CR cheaper CNC fiber laser cutting machine

1.

Import original packaging

fiber

laser cutter machines

, good

bean quality, stable performance, without reflection lens and light path adjustment, maintenance free essentially, 100,000 hours working time

1.

Import original packaging

fiber

laser cutter machines

, good

bean quality, stable performance, without reflection lens and light path adjustment, maintenance free essentially, 100,000 hours working time

2. High rigidity machine bed, adopts exclusive standard annealing processing with high-temperature NC electric resistance furnace, ensure long-time stable precision of the machine tool

3. High transformation efficiency of fiber laser, which up to 30%, saving the working power consumption by a large margin, achieves low operating costs

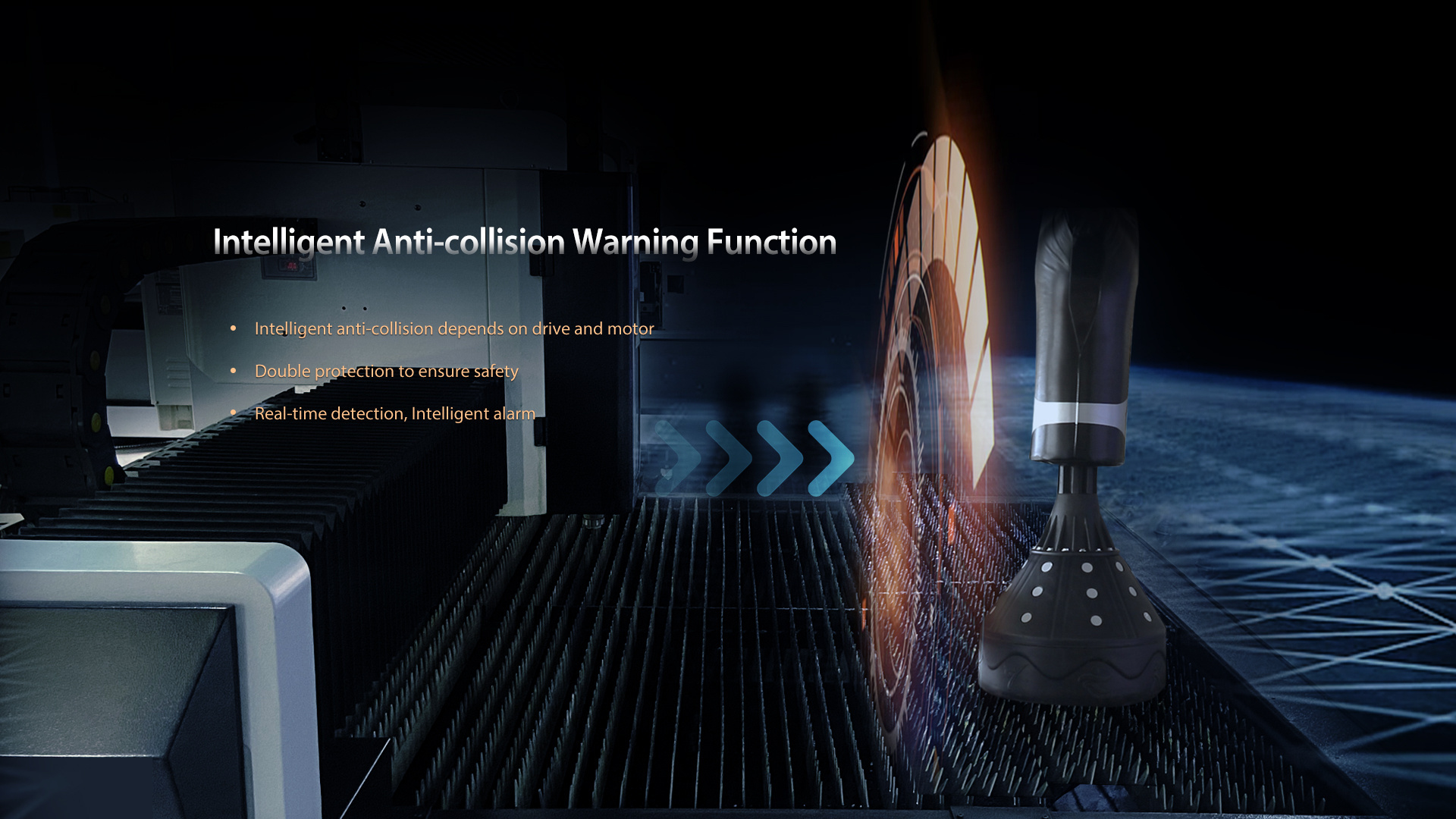

4. Adopts the imported original guide transmission and servo motors, high precision, high speed

5. Smooth cutting edge, little deformation

6. Low power consumption, energy saving, overall power consumption 1/3-1/5 of the same power YAG machines, 3 times sheet metal cutting speed

7. Laser generated without gas, air can be used to cut sheet metal.

Workbench : the carbon fiber laser cutting machine workbench using top and intensive type,with the design of elevating high speed double work table,which can prepare for the next feeding during working,it improve the working efficiency .

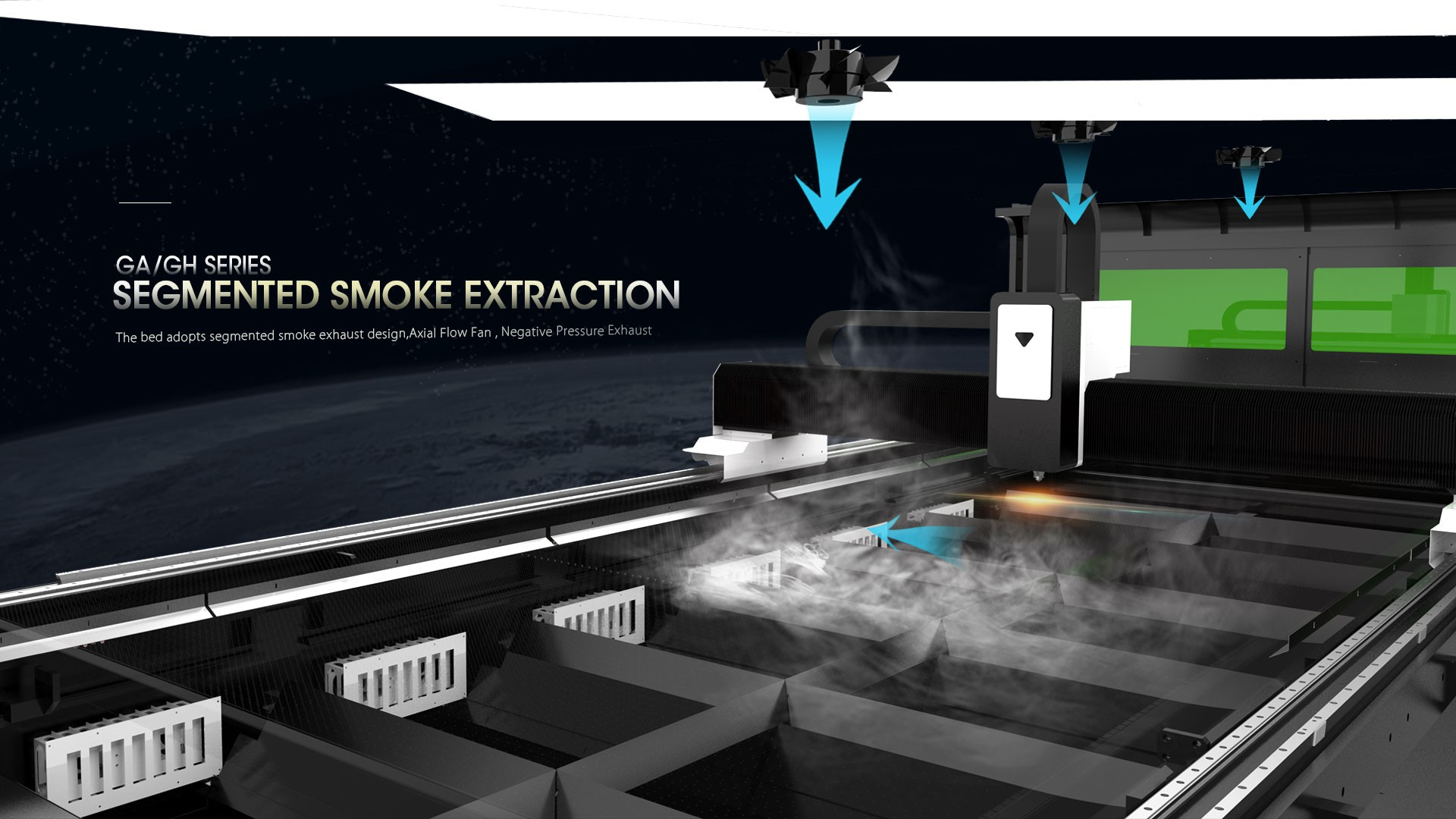

Slagging system : lower bed is equipped with partition to collect ,which can gather the waste and the small component in the process of production.

Dust removal system : the laser cutting machine workbench uses partition vacuuming design, equipped with external oil extraction, which is used for removing dust flue gas and so on in the process of production.

Transmission system : the small fiber laser cutting machine transmission system uses German ATLAMTA pinion and rack for accurate transmission and Japan servo motor

control system :The 500w fiber laser cutting machine operating system can use editing software and secondary development tool to customize the special interface and function,it is easy for customers to create their own man-machine interface.

The most effective-cost fiber laser cutting machine , we manufactuer all kinds of fiber cutting machine , CO2 laser , Marking machine , aluminum cutting machine , cutter machine . Power brand IPG Nlight or Raycus are all available , you can also choose different area of table , open type single table or double auto exchangeble table ,with or without protective cover ,we can customize as you request .

Warranty and service

Three years warranty for

laser cutter machines.

English technical to door service.

English manual and Video CD for laser cutter machines using and maintenance.We offer free training in our factory,

welcome to visit and learn more about our laser cutter machines.

Free accessories :Software ,manual, book, cd videos, USBcontrol

1.Pre-sales service

A. Free sample making

For free sample making/testing, please send your samples or products CAD Graphics to our company in China. Try before you buy.

B. Progressing Solution Design

According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

2.After-sales service:

Training to install(3options):

A. We will supply the machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone/MSN/ICQ and so on, when you meet some problems of installation, using or adjusting.

B. You can come to our factory for training. Gweike will offer professional guide. Direct and effective face-to-face training. Here we have assembled equipments, all sorts of tools and testing facility,we will also provide accomadation during training period. Training Time: 1-10 working days.

Machine will be packed in wooden case. We clean the laser cutter machines before package, and covered anti rust oil, then packed.

1. Anti-collision package edge: All parts of the machine are covered with some soft materials, mainly the use of pearl wool

2. Fumigation wooden box:Our wooden box is fumigated, do not need to check the wood, saving the transport time.

3. Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust. The outermost is a wooden box with a fixed template.

4. Wooden box at the bottom of a solid iron socket for easy handling.