- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Silicone Foam Pad 200323

-

Color:

-

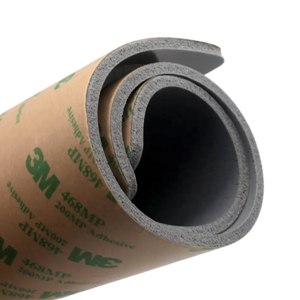

Black/Gray/Orange

-

Thickness:

-

1-25mm

-

Width:

-

460mm to 960mm

-

Density:

-

500 kg/m3

-

Elongation:

-

≥80 %

-

Application:

-

Shock Absorption, buffering, Sound Insulation, Protection

-

Flammability:

-

V0 (UL 94)

-

Tensile Strength:

-

≥300 Kpa

-

Water Absorption:

-

<1.5% (Internal:24h@25℃)

-

Feature:

-

Great Sealing Performance

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

China

-

Brand Name:

-

Leader OPUS

-

Model Number:

-

Silicone Foam Pad 200323

-

Color:

-

Black/Gray/Orange

-

Thickness:

-

1-25mm

-

Width:

-

460mm to 960mm

-

Density:

-

500 kg/m3

-

Elongation:

-

≥80 %

-

Application:

-

Shock Absorption, buffering, Sound Insulation, Protection

-

Flammability:

-

V0 (UL 94)

-

Tensile Strength:

-

≥300 Kpa

-

Water Absorption:

-

<1.5% (Internal:24h@25℃)

-

Feature:

-

Great Sealing Performance

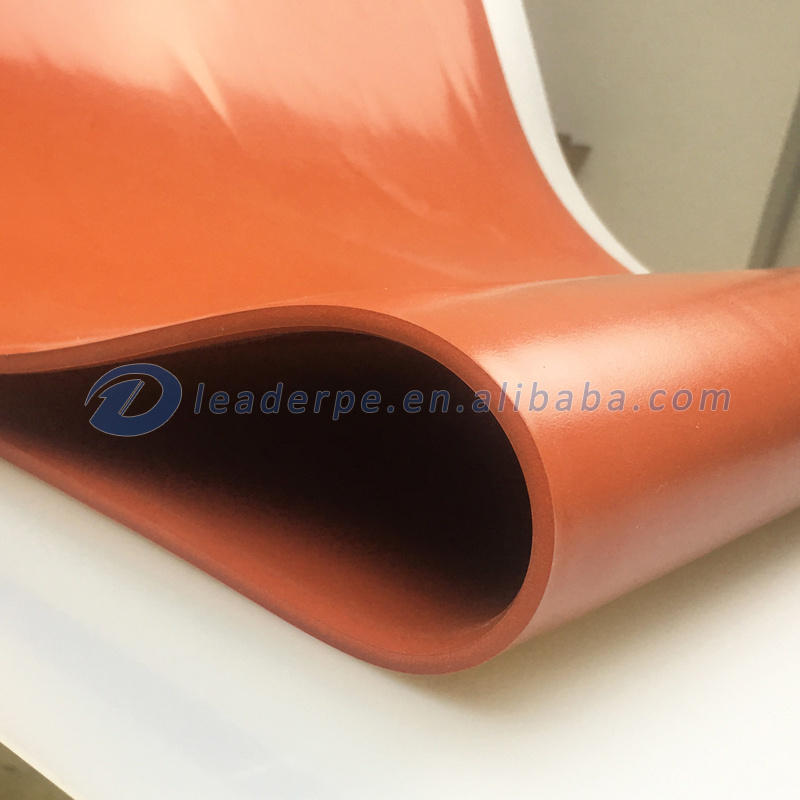

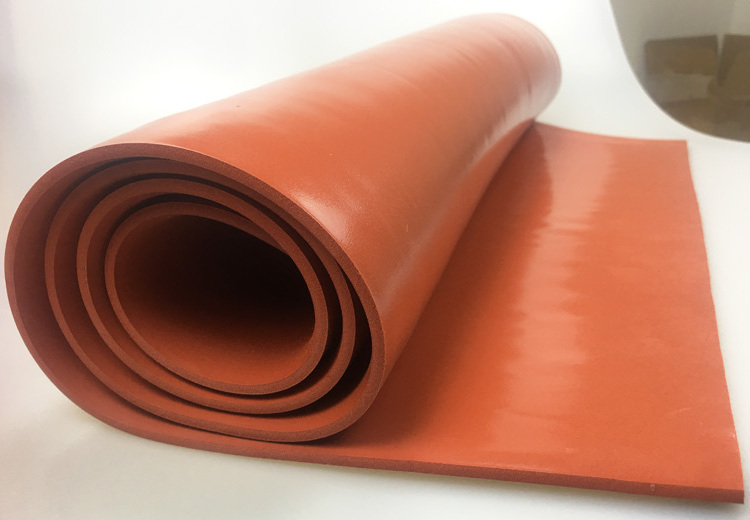

3mm Thin Red Open Cell High Temperature Silicone Rubber Foam Pad Sheet

Excellent Heat Resistance Silicone Foam Pad

Silicone Foam Pad 200323 Silicone Foam Pad

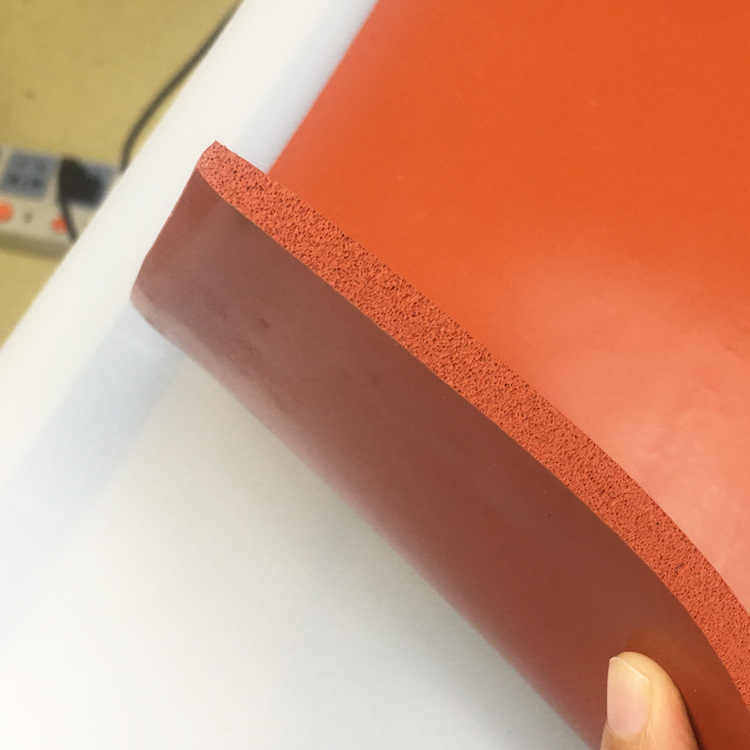

is a highly versatile, middle and upper firmness cellular silicone that offers the lightness of a foam, with the enhanced sealing capabilities of a traditional sponge rubber. It is used to seal and protect various outdoor communication, electronics, and lighting enclosures, while providing protection against wind driven rain and fire. The material is also used to reduce shock or isolate vibration.

Technical Sheet of Silicone Foam Pad

| Property | Test Method | Typical Value |

| Color | ~ | Black/Gray/Orange |

|

Thickness, Millimeter (mm)

Tolerance |

1-25mm | |

| Density (kg/m 3 ) | ASTM D 1056 | 500 kg/m 3 |

| Compression Force Deflection, (Kpa) |

Force measureed@25%

Deflection ASTM D 1056 |

110.0(±15)Kpa |

|

Compression Set

% max |

ASTM D 1056

Test @ 70℃ / 158 ℉ |

<1 |

|

ASTM D 1056

Test @ 100℃ / 212 ℉ |

<4 | |

| Tensile Strength, (kPa) | ASTM 412 | ≥300 |

| Elongation, % | ASTM 412 | ≥80 |

| Water Absorption | Internal:24h@25℃ | <1.5% |

| Dielectric Constant | ASTM D 150 | 1.42 |

|

Volume Resistivity,

Ohm-mm |

ASTM D 257 | 10 13 |

| Low Temperature Flex at 67 ℉ (-55℃) | ASTM C 518 | PASS |

|

Recommended use

Temperature ℉ (℃) |

SAE J-2236 |

-67 to 500

(-55 to 260) |

|

Recommended Intermittent

High Temperature Use ℉ (℃) |

482(250) | |

| Toxic Gas Emissions Rating | SMP-800-C | PASS |

| Flammability | UL 94 | V0 |

REMARK

* Silicone Foam Pad 200323 cellular silicone is available: black, gray and orange, width is available from 460mm to 960mm, thickness is available from 1mm to 25mm.

* Storage Time: 5-8 years in a normal temperature and humidity environment.

* Data for design engineer spec. reference only. Engineers are reminded to test the material in application.

Features of Silicone Foam Pad

Applicaton of Silicone Foam Pad

Why Choose Our Silicone Foam Pad

Silicone foam sheet is a medium stress silicone foam material, which has excellent compression resistance and permanent deformation, compared with the traditional carbon foam material. Our silicone foam sheet has excellent resistance to high and low temperature (-60-200℃), high flame retardant (v-0) very low smoke concentration, excellent weather resistance and aging resistance. It is the great material for shock absorption, buffer, sound insulation, protection and insulation, etc.

BEST Silicone Foam Pad Manufacturer

Leader OPUS a scientific and technological enterprise specialized in the research and development, production and sales of electronics materials and other high technolgical material. We also provide die cutting service for silicone foam shet.