- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

pctfe

-

Product name:

-

PCTFE

-

Melting Index:

-

2.1-5

-

Tensile Strength≥:

-

37 Mpa

-

Relative Gravity:

-

2.10-2.15

-

Melting Point:

-

205-215℃

-

Type:

-

pctfe rod

-

Application:

-

aviation, aerospace, medicine

-

long-term use temperature:

-

-200-120℃

-

processing temperature:

-

not exceed 350℃

-

Elongation at break,≥:

-

35%

Quick Details

-

Processing Service:

-

Cutting

-

Place of Origin:

-

China

-

Brand Name:

-

SHINGCHEM

-

Model Number:

-

pctfe

-

Product name:

-

PCTFE

-

Melting Index:

-

2.1-5

-

Tensile Strength≥:

-

37 Mpa

-

Relative Gravity:

-

2.10-2.15

-

Melting Point:

-

205-215℃

-

Type:

-

pctfe rod

-

Application:

-

aviation, aerospace, medicine

-

long-term use temperature:

-

-200-120℃

-

processing temperature:

-

not exceed 350℃

-

Elongation at break,≥:

-

35%

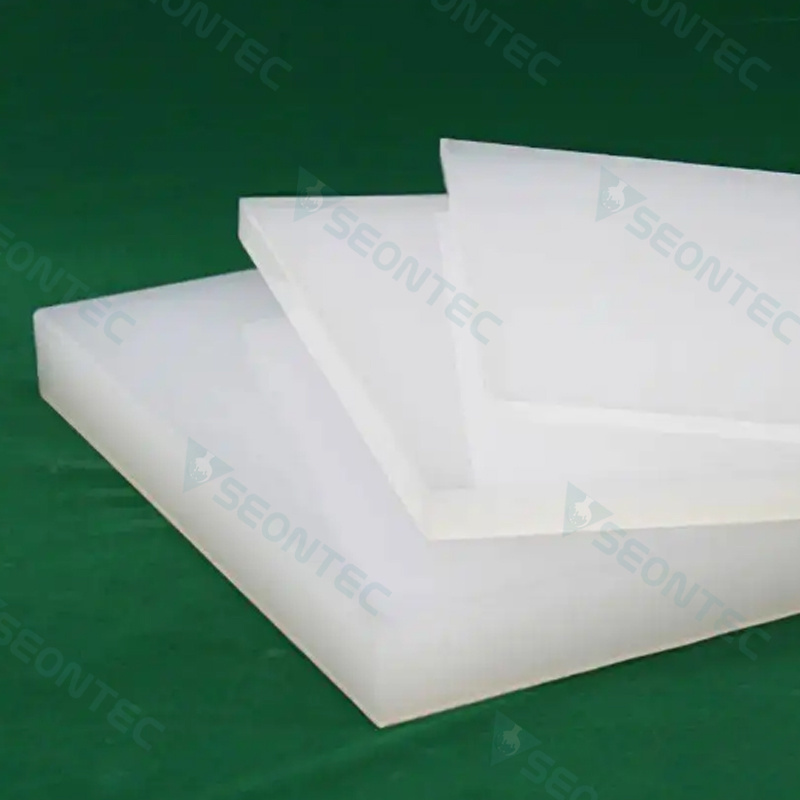

POLYCHLOROTRIFLUOROETHYLENE RESIN

(PCTFE)

Product Description

PCTFE is the homopolymer to chlorotrifluoroethylene, which has excellent water vapor barrier properties, good low temperature resistance and high compressive strenth, and is resistant to various acides, alkalis, oils and most organic solvents. It can be processed by thermoplastic processing methods. Its long-term use temperature is -200-120 ℃ .

Conformable with: Q/0321 DYS 026

Technical index

|

Item |

Unit |

DS800 |

DS801 |

DS802 |

DS803 |

DS804 |

Test Method/standards |

||||

|

Appearance |

/ |

Translucent particle |

Visual inspection |

||||||||

|

Melting Index |

g/10min |

≤ 2 |

2.1-5 |

5.1-12 |

12.1-20 |

> 20 |

GB/T 3682 |

||||

|

Tensile Strength, ≥ |

Mpa |

37 |

37 |

35 |

35 |

30 |

GB/T 1040 |

||||

|

Elongation at break, ≥ |

% |

35 |

GB/T 1040 |

||||||||

|

Relative Gravity |

/ |

2.10-2.15 |

GB/T 1033 |

||||||||

|

Melting Point |

℃ |

205-215 |

GB/T 19466.3 |

||||||||

Application

Mainly used in the aviation, aerospace, medicine, chemical, electrial and other fields.

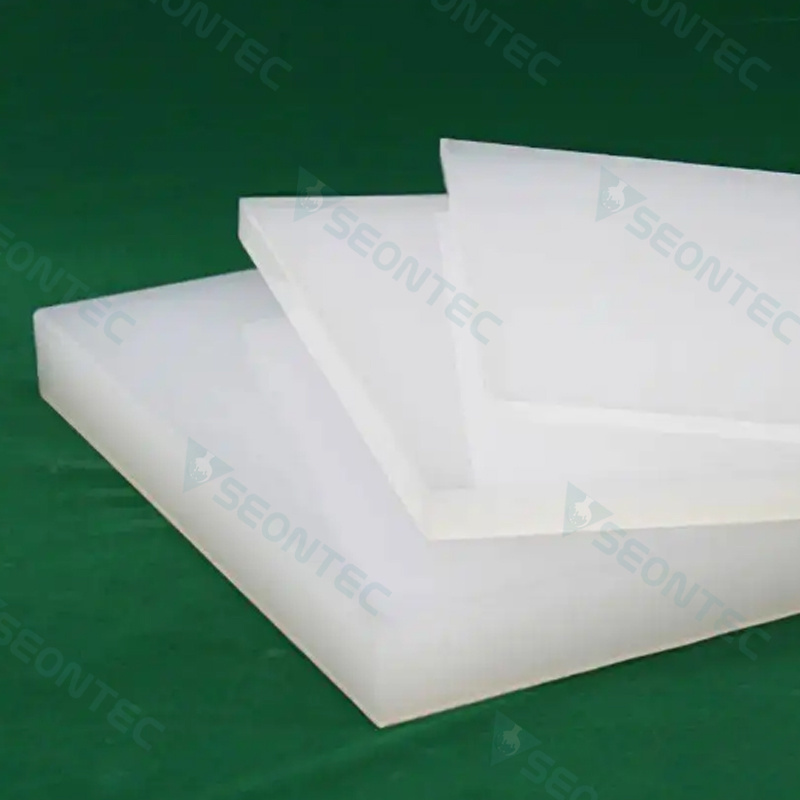

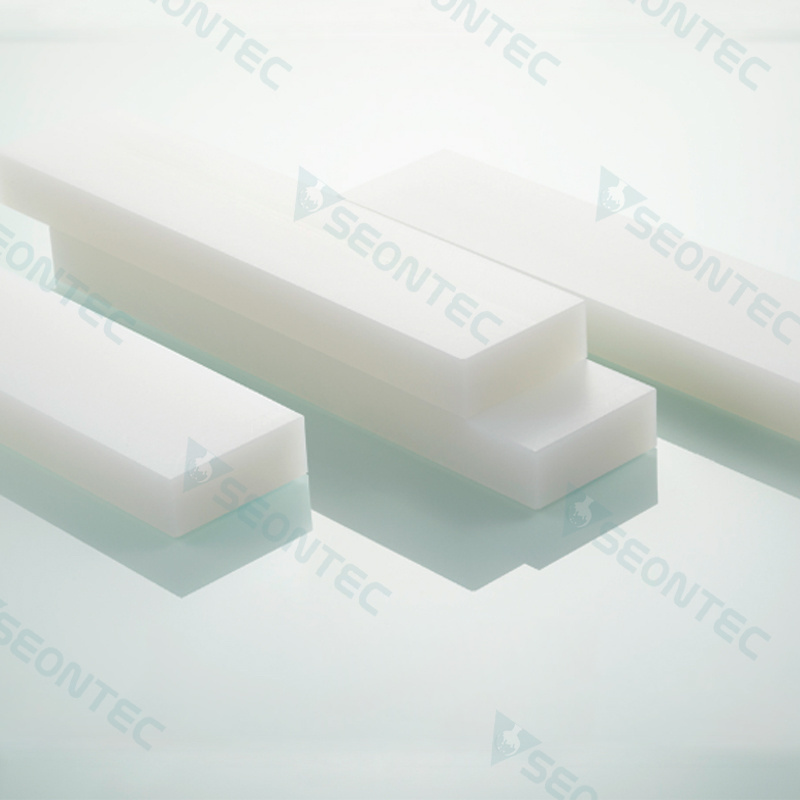

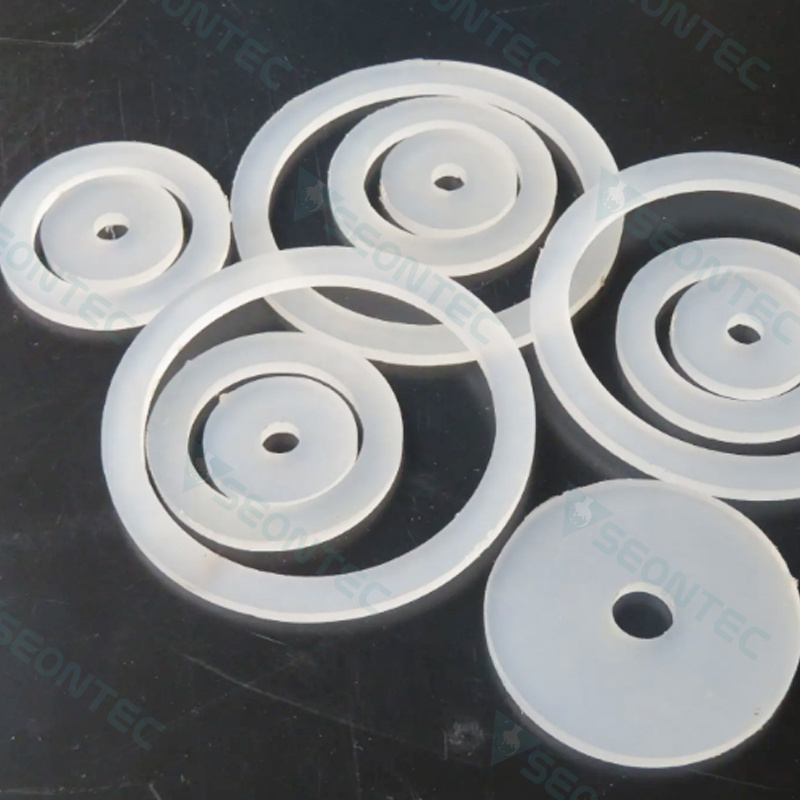

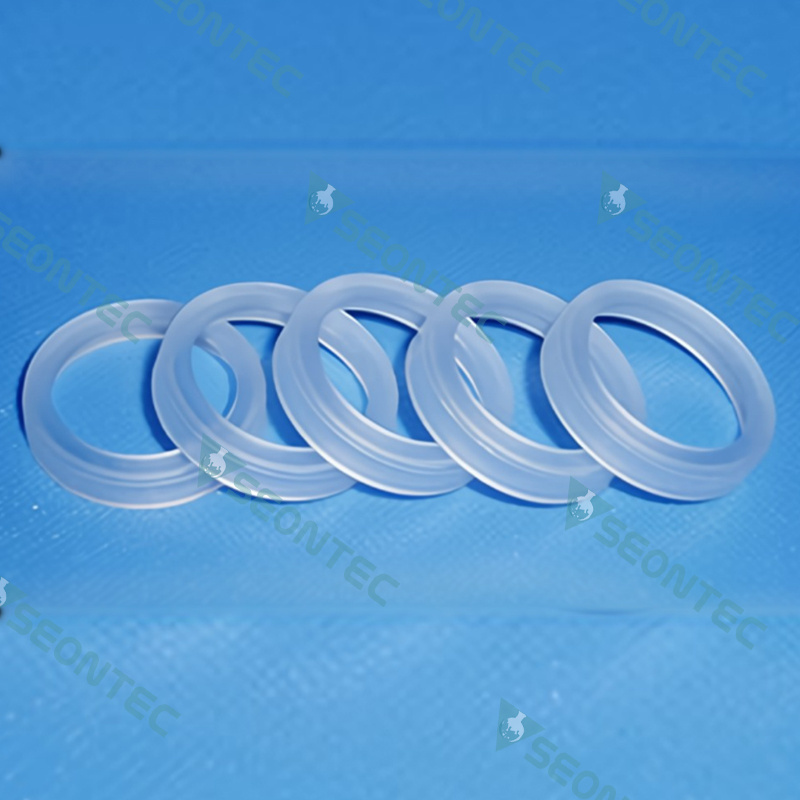

DS800/DS801: The high molecular weight and crack resistance resin, used for compression molding, mainly for plates, rods, tubes, gaskets, seals, etc.

DS802: Suitable for extrusion molding, mainly used for tubes, sheets, films, etc.

DS803: Suitable for extrusion and injection molding, mainly used for films, pumps, valve and other injection parts.

DS804: Suitable for injection molding, mainly used for injection parts, such as pumps and velves.

Attention

The processing temperature should not exceed 350 ℃ to prevent toxic gas from releasing

Package, transportation and storage

1. Packed in plastic bag, and in hard circular barrels outside, Net weight is 25kg per drum.

2. Stored in clean, cool, and dry places. Avoid contamination from foreign substance such as dust and moisure.

3. Nontoxic, noninflammable, inexplosive, nocorrosion, transported as non-dangerous product.