- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

12100*3600*2200mm

-

Weight (KG):

-

5000

-

Power (kW):

-

15

-

Product Name:

-

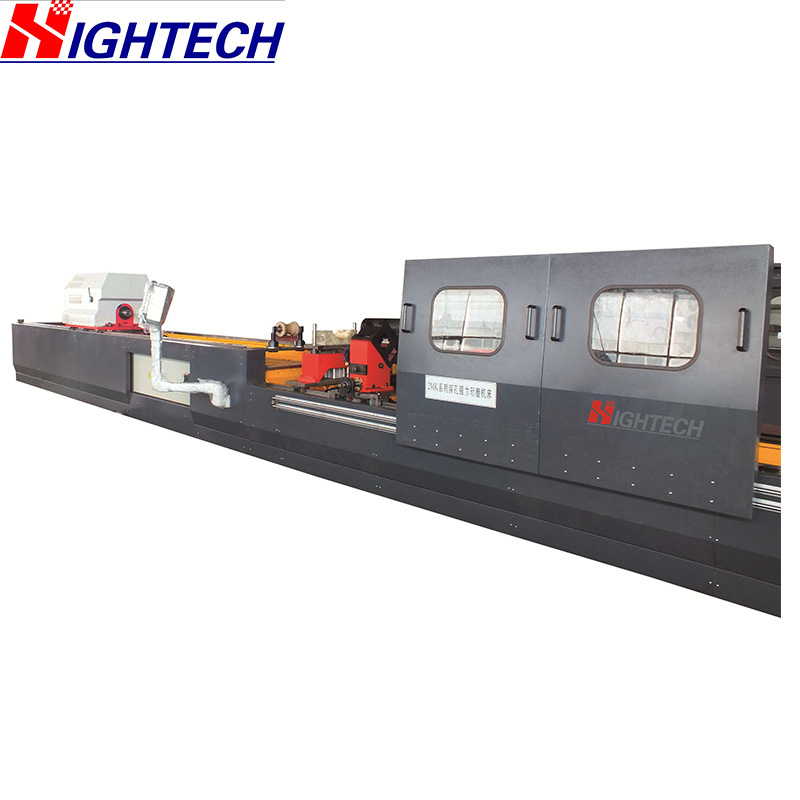

heavy-duty cnc hydraulic tube honing machine

-

Honing Hole Diameter Range:

-

40-500mm

-

Maximum Honing Depth:

-

6000mm

-

Workpiece Clamping Diameter Range:

-

50-600mm

-

Grinding Rod Spindle Center Height:

-

500mm

-

Grinding Rod Box Spindle Rotation Speed:

-

10-350r/min (stepless regulation)

-

Carriage Reciprocating Speed Range:

-

1-28m/min (stepless regulation)

-

Grinding Rob Box Spindle Motor Power:

-

15KW

-

Reciprocating Motor Power:

-

5.5KW (AC servo motor)

-

Grinding Head Expanding Motor Power:

-

0.75KW (AC servo motor)

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HITECH

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

12100*3600*2200mm

-

Weight (KG):

-

5000

-

Power (kW):

-

15

-

Product Name:

-

heavy-duty cnc hydraulic tube honing machine

-

Honing Hole Diameter Range:

-

40-500mm

-

Maximum Honing Depth:

-

6000mm

-

Workpiece Clamping Diameter Range:

-

50-600mm

-

Grinding Rod Spindle Center Height:

-

500mm

-

Grinding Rod Box Spindle Rotation Speed:

-

10-350r/min (stepless regulation)

-

Carriage Reciprocating Speed Range:

-

1-28m/min (stepless regulation)

-

Grinding Rob Box Spindle Motor Power:

-

15KW

-

Reciprocating Motor Power:

-

5.5KW (AC servo motor)

-

Grinding Head Expanding Motor Power:

-

0.75KW (AC servo motor)

Product Pictures

CNC Deep Hole Tube Honing Machine for Deep Hole Cylinder Manufacturing Horizontal Honing Type Tube Honer

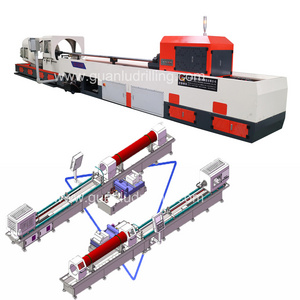

This deep hole honing machine is specialized to process cylindrical deep hole parts.It can drill holes,bore holes and honing.

Inner chip removal method(BTA),which means,oil feeder supplies oil,oil flows through cutting area and brings chips(which is inside boring bar) to the back conveyor of machine.

When boring,it adopts push boring method,oil feeder supplies oil,cooling liquid conveys chips to the head of machine.

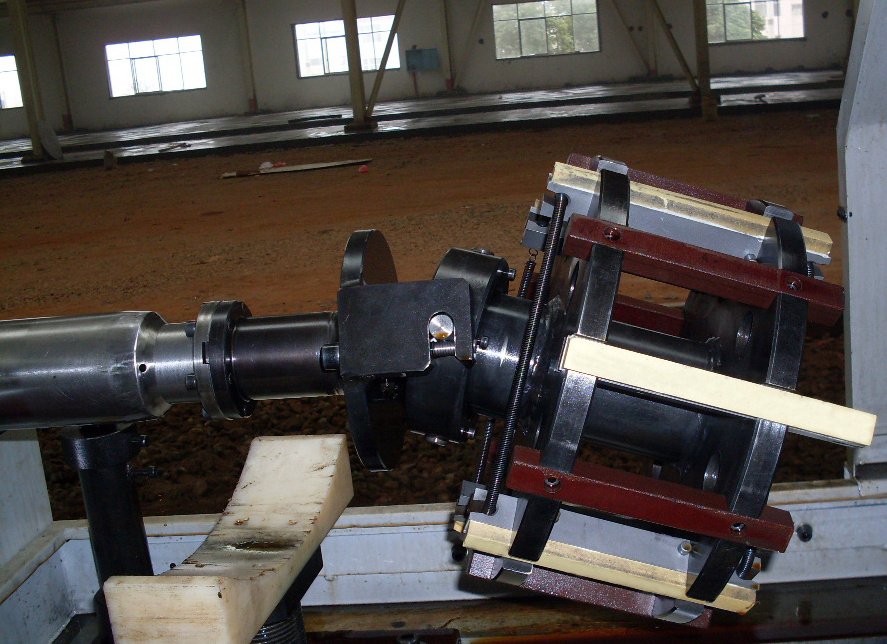

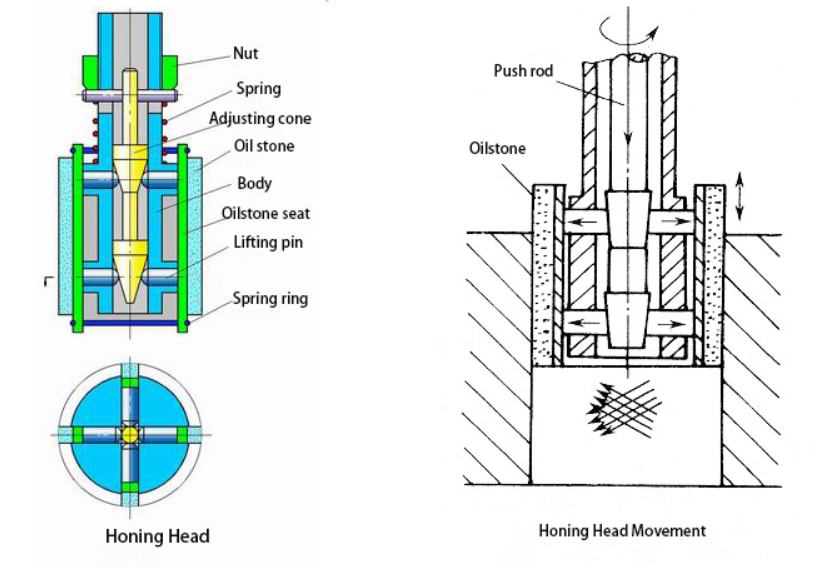

This machine can be also equipped with hydraulic harmomegathus honing head.

Machine has associated hydraulic system,cooling system and chip-removal system.

Inner chip removal method(BTA),which means,oil feeder supplies oil,oil flows through cutting area and brings chips(which is inside boring bar) to the back conveyor of machine.

When boring,it adopts push boring method,oil feeder supplies oil,cooling liquid conveys chips to the head of machine.

This machine can be also equipped with hydraulic harmomegathus honing head.

Machine has associated hydraulic system,cooling system and chip-removal system.

Product Parameters

|

1

|

Honing diameter

|

Φ60~200mm

|

|

2

|

Center height

|

400mm

|

|

3

|

Process depth

|

600~8000mm

|

|

4

|

3-jaw chuck diameter

|

Φ500mm

|

|

5

|

Clamping range of center rest

|

Φ50~400mm

|

|

6

|

Main motor

|

N=30kW,n=1460r/min

|

|

7

|

Spindle speed

|

50~800rpm,12 grades

|

|

8

|

Boring bar box motor

|

N=15kW,n=1460r/min

|

|

9

|

Boring bar box spindle speed

|

50~400rpm,12 grades

|

|

10

|

Feeding speed

|

5~5000mm/min(stepless)

|

|

11

|

CNC system

|

SIEMENS 808D

|

|

12

|

Feed motor

|

40N.M,SIEMENES servo motor

|

|

13

|

Oil feeder motor

|

32N.M,CTB servo motor

|

|

14

|

Cooling pump motor

|

N=5.5kW,n=1440r/min(4 groups)

|

|

15

|

Nominal pressure of cooling system

|

2.5MPa

|

|

16

|

Cooling system flow rate

|

100,200,300,400L/min

|

|

17

|

Cooling tank volume

|

4000L

|

|

18

|

Cooling pump flow rate of honing

|

50L/min

|

|

19

|

Cooling tank volume of honing

|

950L

|

Details Images

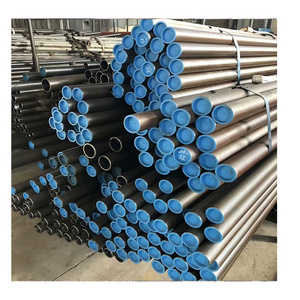

Workpiece

Related Products

ZK Series CNC Deep Hole Drilling Machine

The deep hole drilling machine is mainly used for processing small hole, which has high hole straightness.

T21 Series Deep Hole Drilling and Boring Machine

Deep hole drilling and boring machine is mainly used for hole reaming with large machining allowance.

TGK Series Deep Hole Skiving Roller Burnishing Machine

The main advantages of the skiving roller burnishing machine are good surface roughness and high efficiency. The working efficiency is ten times of ordinary deep hole drilling and boring machine.

Hot Searches