- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

tungsten copper

-

Shape:

-

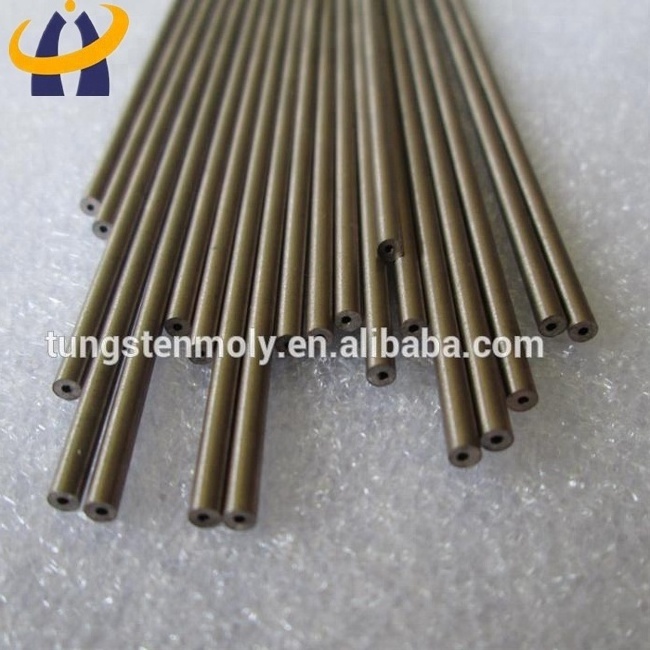

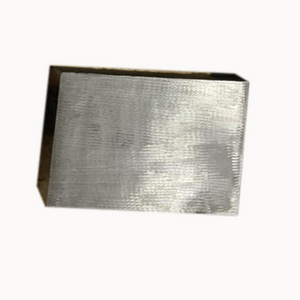

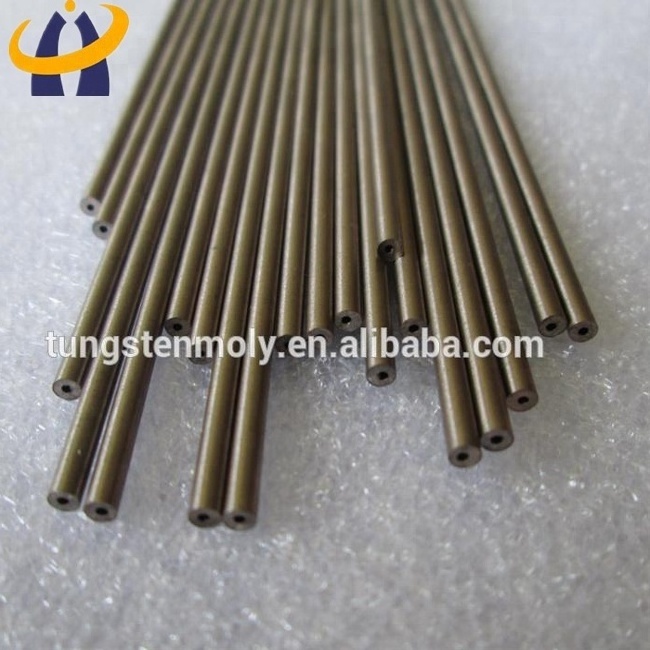

rod, square,bar,plate,sheet,round,

-

Material:

-

tungsten-copper, tungsten copper,copper tungsten alloy,copper tungsten

-

Chemical Composition:

-

wcu,cuw

-

Product name:

-

wcu electrode

-

Surface:

-

Grinding Polished,ground

-

Cu content:

-

10%-50%copper

-

Density:

-

16.5-18.5

-

Feature:

-

high resistance temperature

-

Standard:

-

ASTM-B702

-

Certificate:

-

ISO9001:2008 ISO14001 CE

-

Appearance:

-

copper metal,tungsten metal,gold metal

Quick Details

-

Application:

-

electrode,EDM,ECM etc

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

MINGGUAN

-

Model Number:

-

tungsten copper

-

Shape:

-

rod, square,bar,plate,sheet,round,

-

Material:

-

tungsten-copper, tungsten copper,copper tungsten alloy,copper tungsten

-

Chemical Composition:

-

wcu,cuw

-

Product name:

-

wcu electrode

-

Surface:

-

Grinding Polished,ground

-

Cu content:

-

10%-50%copper

-

Density:

-

16.5-18.5

-

Feature:

-

high resistance temperature

-

Standard:

-

ASTM-B702

-

Certificate:

-

ISO9001:2008 ISO14001 CE

-

Appearance:

-

copper metal,tungsten metal,gold metal

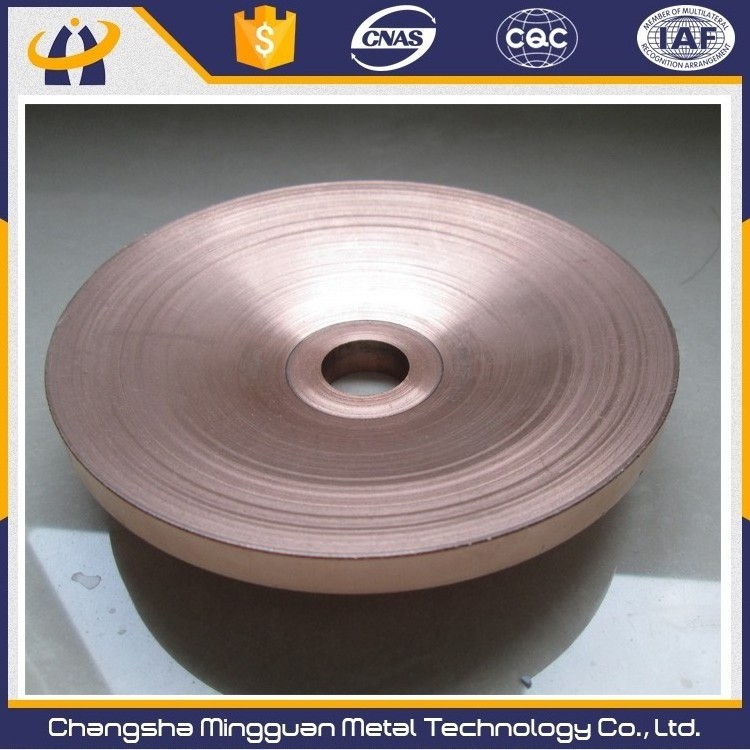

Wholesale wcu cuw electrode EDM copper tungsten alloy disc

tungsten copper

used when a product or part needs to have a high heat resistance, low thermal expansion and high electrical or thermal conductivity. Tungsten copper alloy is used to make engines and electrical devices. It is also used in the fields of aviation and spaceflight. Electrodes, refractory parts, heat sinks, rocket parts and electrical contacts are all made out of tungsten copper alloy. The alloy is also made into sheet metal, tubing and plate metal. Tungsten copper alloy is used to make contacts for both high and low voltage electrical devices, and for high speed steel devices and switches.

Applications of our

tungsten copper disc

Arcing contacts and vacuum contacts in high and medium voltage breakers or vacuum interruptors

Electrodes in electric spark erosion cutting machines

Heat sinks as passive cooling elements of electronic devices

Electrodes for resistance welding

Electronic Packaging Materials

Pictures of our tungsten copper

we can also provide custom made tungsten copper disck for many shapes :

What's Tungsten Copper ?

Tungsten copper alloy (Copper Tungsten Alloy, CuW, or WCu) is a pseudo-alloy of copper and tungsten. As copper and tungsten are not mutually soluble, the material is composed of distinct particles of one metal dispersed in a matrix of the other one. The alloy combines the properties of both metals, resulting in a material that is heat-resistant, ablation-resistant, high thermal and electrical conductivity, and easy to machine. Parts are made from the WCu alloy by pressing the tungsten particles into a desired shape, sintering the compacted part, then infiltrating with molten copper. Sheets, rods and bars of the alloy are available as well.

Tungsten copper parts provided by us are all with these properties. The electrical and thermal properties of the alloy vary with different proportions. Copper increases the thermal conductivity, which plays a huge part when being used in circuit breakers. Electrical resistivity with an increase in the percentage of tungsten present in the alloy, ranging from 3.16 at 55% tungsten to 6.1 when the alloy contains 90% tungsten. An increase in tungsten leads to an increase in ultimate tensile strength up until the alloy reaches 80% tungsten and 20% copper with an ultimate tensile strength of 663 MPa. After this mixture of copper and tungsten, the ultimate tensile strength then begins to decrease fairly rapidly.

Chemical Composition of our tungsten copper

|

Class

|

Chemical Composition(Wt%)

|

|

|

Density

|

Hardness

|

Resistance rate

|

IACS

|

Bending strength

|

||

|

|

Cu

|

Total Additives≤

|

W

|

g/cm3≥

|

kgf/mm4≥

|

um.cm≤

|

%≥

|

MPa≥

|

||

|

W93Cu07

|

7±1.0

|

0.5

|

balance

|

17.5

|

270

|

7.2

|

26

|

1190

|

||

|

W90Cu10

|

10±2.0

|

0.5

|

balance

|

16.75

|

260

|

6.5

|

27

|

1160

|

||

|

W85Cu15

|

15±2.0

|

0.5

|

balance

|

15.90

|

240

|

5.7

|

30

|

1080

|

||

|

W80Cu20

|

20±2.0

|

0.5

|

balance

|

15.15

|

220

|

5.0

|

34

|

980

|

||

|

W75Cu25

|

25±2.0

|

0.5

|

balance

|

14.50

|

195

|

4.5

|

38

|

885

|

||

|

W70Cu30

|

30±2.0

|

0.5

|

balance

|

13.80

|

175

|

4.1

|

42

|

790

|

||

|

W65Cu45

|

35±2.0

|

0.5

|

balance

|

13.30

|

155

|

3.9

|

44

|

650

|

||

|

W60Cu40

|

40±2.0

|

0.5

|

balance

|

12.75

|

140

|

3.7

|

47

|

600

|

||

|

W55Cu45

|

45±2.0

|

0.5

|

balance

|

12.30

|

125

|

3.5

|

49

|

565

|

||

|

W50Cu50

|

50±2.0

|

0.5

|

balance

|

11.85

|

115

|

3.2

|

54

|

534

|

||

Q:What's your main products?

A:Tungsten /molybdenum /tungsten alloy products.tungsten copper

Q: Why should I choose your company for partner?

A: As you know, the raw material of low price makes your product more competitive in the market. That means it will make your sell much easier.

Q:Do you use first class tungsten /molybdenum powder?

A:We only use first class tungsten / molybdenum powder,no recycle.

Q Delivery tungsten alloy products can be shorter?

A: Usually we make sure all the order delivery with 30 days.Tungsten copper 15 days.

Q:Price can be cheaper?

A: We use first class tungsten powder,the cost is high.

Q:Tungsten /Molybdenum products MOQ?

A:Please email to enquire per different products.

Q:Tungsten /Molybdenum sample?

A:Sample available,within 7~14 days.