- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LUYANGWOOL

-

Model Number:

-

STD/HP/HA/HZ

-

Application:

-

Thermal Insulation

-

Dimensions:

-

Customer Requestion

-

Working Temperature:

-

1100℃/1260℃/1350℃/1430℃/1600℃

-

Fiber Diameter:

-

3-5μm, 3-5/3-5/2-4/3-5

-

Thermal Conductivity:

-

0.075

-

Shrinkage (1800℉, 3h):

-

3%(24hours)

-

Classification:

-

STD/HP/HA/HZ

-

AL2O3:

-

≥43/44/52/35

-

SiO2:

-

≥54/55/47/49

-

Shot content:

-

≤15/15/15/12

-

Classification temperature:

-

1260/1260/1350/1430

-

Feature 1:

-

Excellent thermal shock resistance

-

Feature 2:

-

Low thermal conductivity

-

Typical Application 1:

-

Insulating fill for complex spaces and difficult access

-

Typical Application 2:

-

Kiln car infill

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

-

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LUYANGWOOL

-

Model Number:

-

STD/HP/HA/HZ

-

Application:

-

Thermal Insulation

-

Dimensions:

-

Customer Requestion

-

Working Temperature:

-

1100℃/1260℃/1350℃/1430℃/1600℃

-

Fiber Diameter:

-

3-5μm, 3-5/3-5/2-4/3-5

-

Thermal Conductivity:

-

0.075

-

Shrinkage (1800℉, 3h):

-

3%(24hours)

-

Classification:

-

STD/HP/HA/HZ

-

AL2O3:

-

≥43/44/52/35

-

SiO2:

-

≥54/55/47/49

-

Shot content:

-

≤15/15/15/12

-

Classification temperature:

-

1260/1260/1350/1430

-

Feature 1:

-

Excellent thermal shock resistance

-

Feature 2:

-

Low thermal conductivity

-

Typical Application 1:

-

Insulating fill for complex spaces and difficult access

-

Typical Application 2:

-

Kiln car infill

Products Description

LUYANGWOOL ®

Luyangwool ®

bulk is manufactured from high purity alumina-silica materials through spinning operation or blowing operation. These bulks are loose, long and flexible with fine thermal properties, and can be further modified by chopping. In addition, Lubricant can be added to the fibers. Luyangwool ® bulk serves as the foundation for fiber products such as blanket, board, paper and other vacuum-formed products. At present, the chopped fibers for vacuum formed production, the lubricated bulk fibers and the fiber for textiles are all available. Luyangwool ® fibers are available in a variety of chemistries and diameters which can offer a wide variety of applications.

Features

Low heat storage and thermal conductivity

Excellent chemical and thermal stability

Contains no bonding agent and corrosive substance

Thermal shock resistance and acoustic absorption

Asbestos free and flexible applications

Low heat storage and thermal conductivity

Excellent chemical and thermal stability

Contains no bonding agent and corrosive substance

Thermal shock resistance and acoustic absorption

Asbestos free and flexible applications

Typical Parameters

-----------------------------LUYANGWOOL®-------------------------------

|

Description

|

LUYANGWOOL® STD BULK

|

|

|

|||

|

|

SPUN

|

BLOWN

|

CHOPPED

|

|||

|

Classification Temperature (℃ )

|

1260

|

1260

|

1260

|

|||

|

Chemical Composition (%)

|

|

|

|

|||

|

Al2O3

|

≥43

|

≥43

|

≥43

|

|||

|

SiO2

|

≥54

|

≥54

|

≥54

|

|||

|

ZrO2

|

-

|

-

|

-

|

|||

|

Color

|

White

|

White

|

White

|

|||

|

Shot Content (%)

|

≤15

|

≤15

|

≤12

|

|||

|

Fiber Diameter (μm)

|

3-5

|

2-4

|

2-4

|

|||

|

Description

|

LUYANGWOOL®

HP BULK

|

LUYANGWOOL®

HA BULK

|

LUYANGWOOL®

HZ BULK

|

|||

|

Classification Temperature (℃ )

|

1260

|

1350

|

1430

|

|||

|

Chemical Composition (%)

|

|

|

|

|||

|

Al2O3

|

≥44

|

≥52

|

≥35

|

|||

|

SiO2

|

≥55

|

≥47

|

≥49

|

|||

|

ZrO2

|

-

|

-

|

≥15

|

|||

|

Color

|

White

|

White

|

White

|

|||

|

Shot Content (%)

|

≤15

|

≤15

|

≤12

|

|||

|

Fiber Diameter (μm)

|

3-5

|

2-4

|

3-5

|

|||

Application

|

|

Typical Applications

|

|

1

|

Insulating fill for complex spaces and difficult access

|

|

2

|

Packing expansion Joints

|

|

3

|

Kiln car infill

|

|

4

|

Fire door infill

|

|

5

|

Raw material for finished ceramic fiber products

|

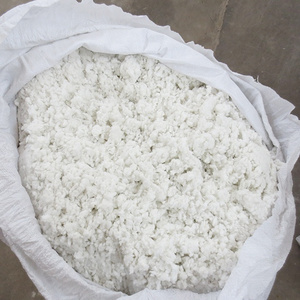

Packing & Delivery

Our service

Pre-Sales Service

* We supply OEM for trading company.

* We can delivery product in 2-7 days.

* We can provide free samples.

* We can delivery product in 2-7 days.

* We can provide free samples.

* We supply designing plan.

After-Sales Service

* Training how to install the products.

* Engineers available to do service overseas.

* Engineers available to do service overseas.

Hot Searches