- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YD

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

Can Choose

-

Warranty:

-

1 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Quality:

-

304/316 SS/Q 235 CS

-

Material:

-

Stainless Steel Snd Carbon Steel

-

Volume:

-

30-5000KG

-

Model:

-

Blender

-

Automatic Grade:

-

Automatic

-

Use For:

-

Concrete,Additive,Pigment

-

Certification:

-

CE/ISO, CE ISO

-

Price:

-

Competitive

-

Machine Type:

-

Mixer

-

Color:

-

Can Choose

-

Power:

-

2.2-75KW

Quick Details

-

Model Number:

-

WHJ Series

-

Max. Loading Capacity:

-

5000KG

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YD

-

Voltage:

-

220V/380V/415V

-

Dimension(L*W*H):

-

Can Choose

-

Warranty:

-

1 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Quality:

-

304/316 SS/Q 235 CS

-

Material:

-

Stainless Steel Snd Carbon Steel

-

Volume:

-

30-5000KG

-

Model:

-

Blender

-

Automatic Grade:

-

Automatic

-

Use For:

-

Concrete,Additive,Pigment

-

Certification:

-

CE/ISO, CE ISO

-

Price:

-

Competitive

-

Machine Type:

-

Mixer

-

Color:

-

Can Choose

-

Power:

-

2.2-75KW

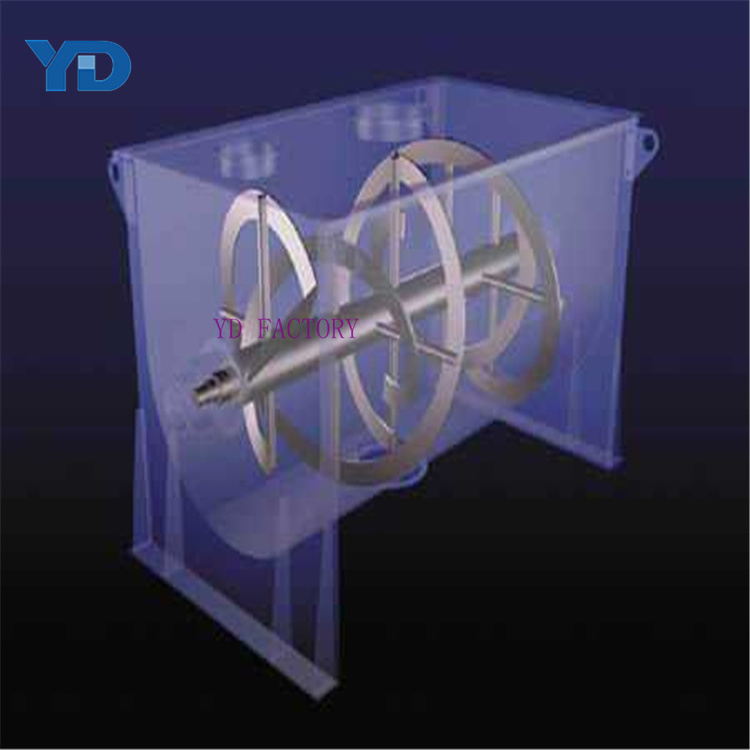

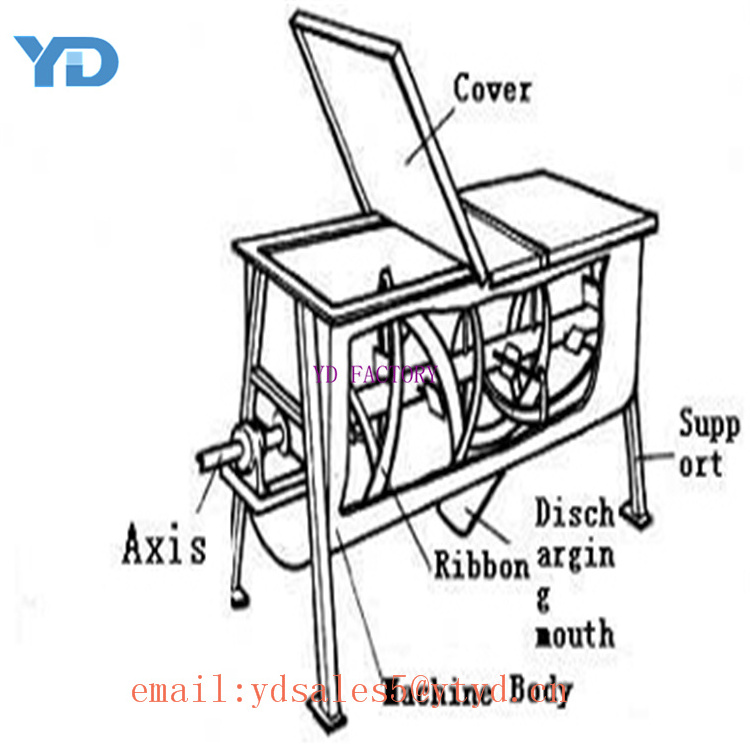

Horizontal Mixer/ Fertilizer Mixing Machine/ Manure Fertilizer Mixing Machine

Introduction

Horizontal uniaxial double ribbon mixer is a dry, powdery material that serves to mix and stir well. During mixing, materials in the plane are moved by two rotors moving in the opposite direction, and the compound movement is carried out. The blades drive the material to rotate clockwise and counterclockwise along the inner wall of the machine groove, and the material near the axis rotates around the axis, Driven by both sides, the external screw drives the material near the wall of the cylinder to rotate in an axial direction, and the axial direction is pushed from both sides to the inside. As a result, convection and circulation of the material cylinder are caused, shear and seepage mixing is completed, and the material is quickly and evenly mixed in a short period of time.

Our ribbon mixer can be equipped with heating or cooling jacket if temperature control is required. Besides, all of our powder mixer can tolerate about 10% liquid additives! We will add spraying or atomizing unit inside the tank!

Features:

1. Using internal and external double helical ribbon staggered back and forth mixing, mixing speed, high uniformity

2 bearings at both ends of the mixer, the material is not easy to access, low maintenance.

3. Screw conveyor convenient feeding, feeding port flush with the ground, feeding labor-saving convenience.

About Delivery time

Q-----What’s the delivery term for making business with us?

A-----Usually we send tne shipments in FOB term.However, the terms of CIF are acceptable which depend on the preference of clients.

About Lead Time

Q------What’s the lead time after placing thr order?

A------Usually it takes about 25~30 days after we received your confirmation.

However, it would depend on our production line schedule(the timing clients place order)and the complication of the item.

About Payment Term

Q------What’s the Payment Term?

A------By T/T in Advance, or Irrevocable L/C as Sight.