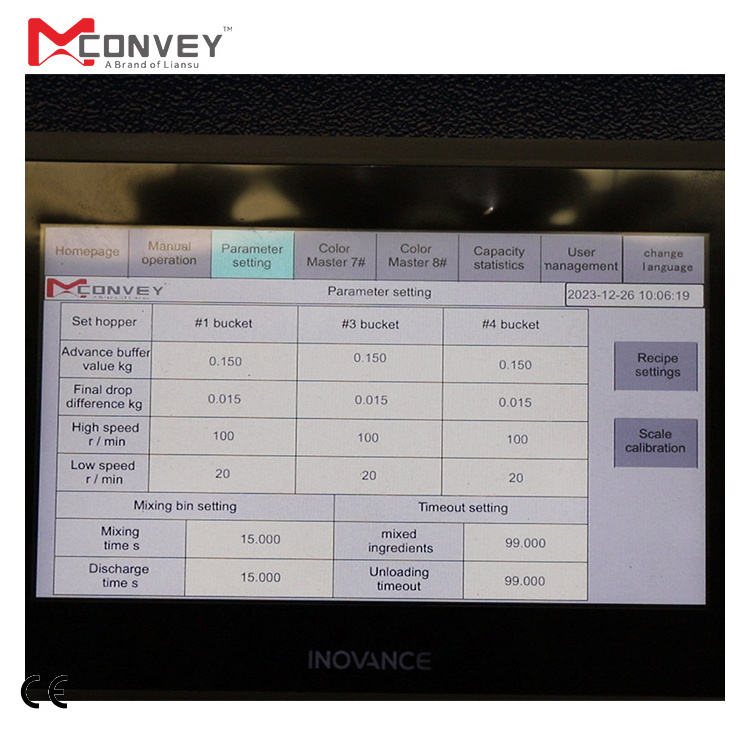

b. Flexible to add or reduce component without changing model.

c. Most of components adopt quick disassembly design, which is convenient for material replacement and cleaning.