- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yuanzhen

-

Dimension(L*W*H):

-

1450*1650*3600mm

-

Weight:

-

1400 kg

-

Product name:

-

Pulse Baghouse Dust Collector

-

Application:

-

Metallurgy, building materials, machinery, chemical industry, mining

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Minimum Particle Size:

-

0.3 micron

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuanzhen

-

Dimension(L*W*H):

-

1450*1650*3600mm

-

Weight:

-

1400 kg

-

Product name:

-

Pulse Baghouse Dust Collector

-

Application:

-

Metallurgy, building materials, machinery, chemical industry, mining

Products Description

High efficiency industrial dust removal equipment

- Bag filter

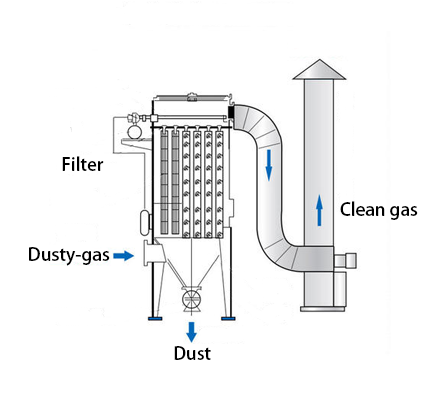

Pulse type dust collector is designed on the basis of jet pulse bag dust collector, the equipment is suitable for dispersed small air volume of dust raising point dust removal selection and process arrangement is relatively simple.

Pulse dust collector has the advantages of good dust cleaning effect, high purification efficiency, large air volume, long filter bag life, small maintenance workload, safe and reliable operation, widely used in metallurgy, building materials, machinery, chemical industry, mining and other industrial and mining enterprises of non-fiber industrial dust dust removal and purification.

Structural principle

When the dusty gas enters the dust collector from the air inlet, it first encounters the inclined partition in the middle of the air inlet, and the airflow turns to flow into the dust hopper, while the airflow slows down, and due to inertia, the coarse dust particles in the gas fall directly into the dust hopper, which plays the role of pre-collecting dust, and the airflow entering the dust hopper folds upward through the filter bag with metal skeleton inside, and the dust is collected on the outer surface of the filter bag, and the purified gas enters the filter bag chamber. The cleaned gas enters the clean room on top of the filter bag chamber and is collected and discharged to the outlet pipe. The air inlet of the dust collector is located on the ash hopper, and the airflow enters the ash hopper and first touches the baffle plate at the end of the inlet pipe, which has the same function as the above principle.

Product Features

1. pulse dust collector cleaning cycle is short, low energy consumption, effectively extend the life of the filter bag.

2. the filter bag mouth adopts elastic up ring, good sealing performance, firm and reliable.

3. Dust skeleton adopts round shape, which reduces the friction between the filter bag and skeleton and facilitates the unloading of the bag.

4. Compact arrangement of inlet and outlet ducts, low airflow resistance.

5. When replacing the dust bag, the skeleton is withdrawn first and the bag is dropped into the dust hopper and taken out by the inlet hole, so it is convenient to change the bag.

Common Model

|

Model

|

YZ-36-27

|

YZ-49-37

|

YZ-64-48

|

YZ-72-54

|

YZ-81-61

|

YZ-90-68

|

YZ-100-75

|

YZ-121-90

|

||||||||

|

Number of filter bags

|

36

|

49

|

64

|

72

|

81

|

90

|

100

|

121

|

||||||||

|

Filtration area(㎡)

|

27

|

37

|

48

|

54

|

61

|

68

|

75

|

90

|

||||||||

|

Filtration air speed

(m/min)

|

1.0-1.4

|

|

|

|

|

|

|

|

||||||||

|

Treatment air volume

(m³/h)

|

1600-2200

|

2200-3100

|

2800-4000

|

3200-4500

|

3600-5000

|

4000-6500

|

4500-7200

|

5400-8600

|

||||||||

|

Flue gas temperature

(℃)

|

≤250

|

|

|

|

|

|

|

|

||||||||

|

Equipment resistance

(Pa)

|

≤1200

|

|

|

|

|

|

|

|

||||||||

|

Inlet concentration

(g/m³)

|

<100

|

|

|

|

|

|

|

|

||||||||

|

Pressure for ash cleaning

(MPa)

|

0.5-0.7

|

|

|

|

|

|

|

|

||||||||

|

Air consumption of compressed air

(m³/min)

|

0.14

|

0.18

|

0.20

|

0.245

|

0.245

|

0.29

|

0.29

|

0.34

|

||||||||

|

Number of pulse valves

|

6

|

7

|

8

|

9

|

9

|

10

|

10

|

11

|

||||||||

|

Fan power

(kW)

|

2.2

|

3.0

|

3.0

|

4.5

|

5.5

|

5.5

|

5.5

|

7.5

|

||||||||

|

Machine weight(kg)

|

1485

|

1650

|

1850

|

2150

|

2750

|

2750

|

3000

|

3400

|

||||||||

|

Weight without ash hopper(kg)

|

1350

|

1500

|

1700

|

2000

|

2500

|

2500

|

2700

|

3000

|

||||||||

|

Support customized production(

Click here to get accurate quotation

)

|

|

|

|

|

|

|

|

|

||||||||

How to select the right type?

Attention:

The selection of screening equipment and your use of demand has a lot to do with the following information you need to provide.

Ⅰ.If you have ever used the screen machine

Kindly please tell us its

Model、Size、

Specific parameters.

Ⅱ. If never use the machine until now

Please provide the following specific requirements

:

1.

Dust type (welding fumes, flying dust, etc.)

2.

Clean area (such as the area of the plant that needs dust removal).

In this way,we can precisely choose the matching model for you to meet your use requirements.

3.

Voltage(V),Frequency(Hz),Phase(P)

---------------------------------------------------------------------------------------------------------

In order to make it more convenient for you, you can compare the following table to clear your machine configuration

Show Details

Product Show

We provide you with quality products and services.

---------------------------------------------------------------------------------------------------------

Please click on the pictures below to learn about related products

Application

Application Scenario Description:

The b

ag pulse d

ust collector

is widely used in metallurgy, building materials, machinery, chemical industry, mining and other industrial and mining enterprises of various non-fibrous industrial dust dust removal and purification.It can

meet the dust recovery and air purification needs of the work shop.

Customer Case

Why Choose Us

About Yuanzhen

Henan Yuanzhen Machinery Equipment Co., Ltd. is an enterprise integrating production, technology research and development, and trade. Our main products are screening equipment and conveying equipment, and we can also provide design, production and installation of other related equipment.

Yuanzhen’s sales network has penetrated the whole China, and many products have gone to the world through other foreign trade companies. Now it is necessary to build a more complete sales network so that users in more countries can use our products and feel our dedicated service.

Yuanzhen sincerely treat every customer, hope to make friends with people from all over the world, and very looking forward to establishing a long-term win-win partnership with you.

Our Team & Service

Basis service

1.Your sample material can be free analysis in our laboratory.

2.24 hours a week online & quick response within 12 hours.

3.Production lead time and delivery time guaranteed.

Customized services

1.Professional R & D team to develop the new products as you requirements.

2.Help customers to develop the local market

3.All packing and shipping can customized as per your requirements.

After-sale services

After customers received the goods,if have any questions or quality problems, Our customer service Dept. will

be always available.

be always available.

Packaging & Shipping

FAQ

Q:What is the quality of the product?

A:We have complete quality control system. We have team leader, section leader and quality control manager to control the quality by each step. Welcome to our factory for cooperation!

Q:What factors I need to get a quotation?

A: Name & bulk density of materials;Capacity per hour;Mesh size and decks;Material of the machine;Voltage Frequency(Hz).

Q:How about price?

A:We are a factory, we provide you with quality and reliable products while giving you better prices, "high cost performance" - that's what we are.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include.)

Q:Service and Payment Terms?

A:We usually accept T/T, L/C;

T/T: 30% in advance as down payment, the balance before delivery;

We take pictures of finished products before delivery.

---------------------------------------------------------------------------------------------------------

If you need accessories, please click on the picture below to enter

Hot Searches