- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Prodrill

-

Dimension(L*W*H):

-

B124*63*32 GC 46 K

-

Weight:

-

20 kg

-

Item:

-

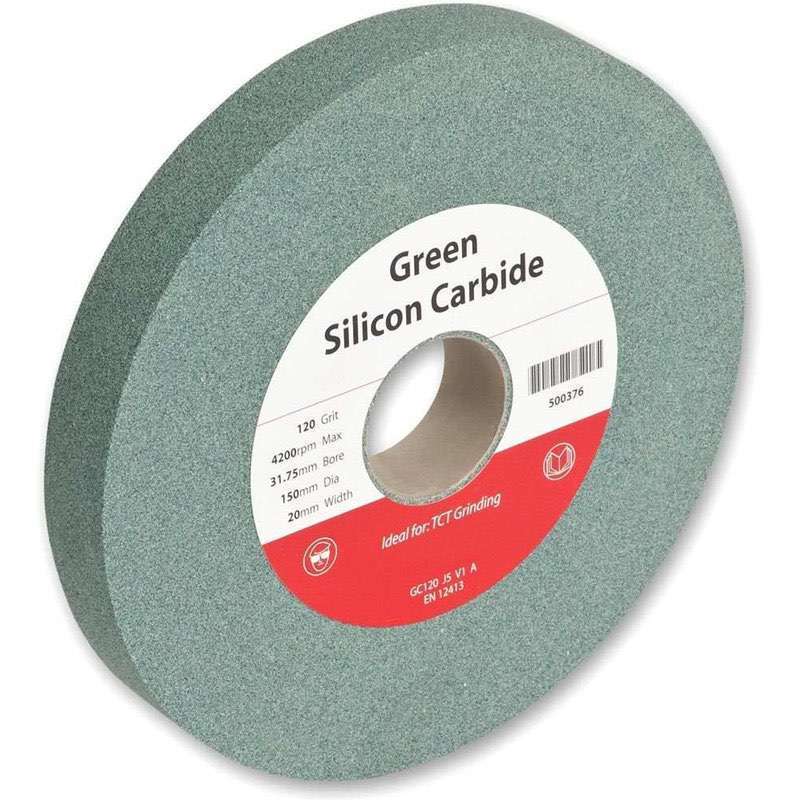

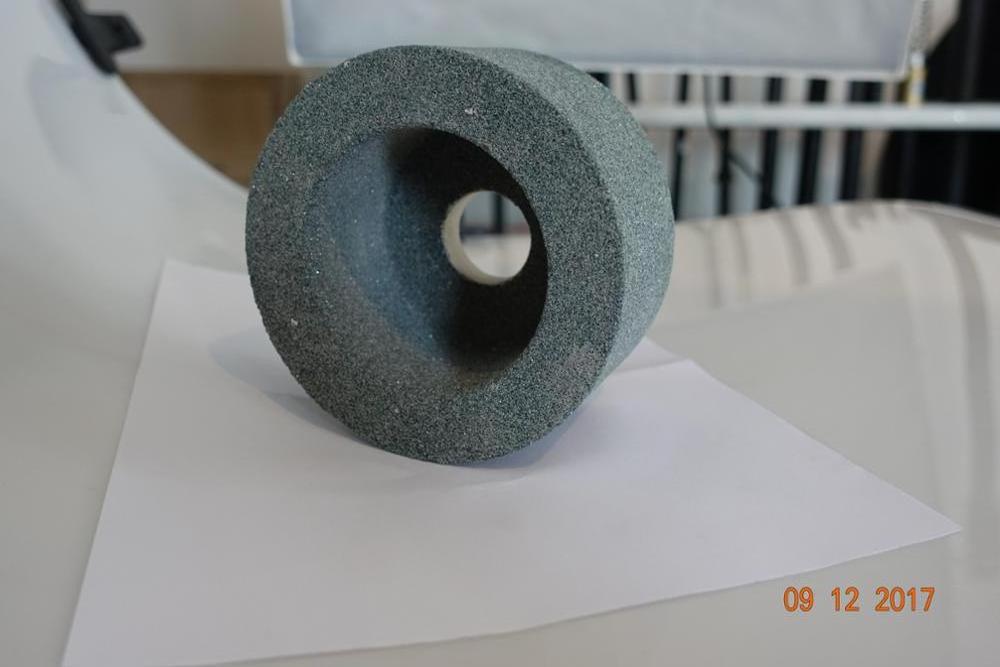

Grinding Wheels

-

Shape:

-

Flat/disc/cup

-

Viscosity:

-

6

-

Abrasive:

-

Silicon Carbide

-

Business Type:

-

Manufacturer

-

Model type:

-

B125*65 * 31.75 GC,B200*25 * 31.75 GC ,B150*65 * 31.75 GC

-

Usage:

-

for grinding Tapered Chisel Bits and Integral Drill Rods

-

Application:

-

sharpening integral chisel drill steels and tapered chisel bits

-

Packing:

-

carton

Quick Details

-

Type:

-

Stone Grinding Machine

-

Power:

-

Other

-

Cutting thickness (max):

-

Other

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Prodrill

-

Dimension(L*W*H):

-

B124*63*32 GC 46 K

-

Weight:

-

20 kg

-

Item:

-

Grinding Wheels

-

Shape:

-

Flat/disc/cup

-

Viscosity:

-

6

-

Abrasive:

-

Silicon Carbide

-

Business Type:

-

Manufacturer

-

Model type:

-

B125*65 * 31.75 GC,B200*25 * 31.75 GC ,B150*65 * 31.75 GC

-

Usage:

-

for grinding Tapered Chisel Bits and Integral Drill Rods

-

Application:

-

sharpening integral chisel drill steels and tapered chisel bits

-

Packing:

-

carton

General introduction:

General introduction:

|

Grinding Wheel ( Grinding stone ) is a real and first class quality sand wheel for grinding Tapered Chisel Bits and Integral Drill Rods to cycle and extend the use life of bits and drill rods and then achieves less cost of drilling cost at certain level for your drilling benefits.

Made of first class quality silicon carbide, it ensure the abrasion resistance of our Grinding Wheel ( Grinding Stone) . Used for grinding the chisel bits and integral drill rod. Through grinding, you can prolong the life span of your drill bit or rods, to reduce your drilling cost. Offer Grinding Wheels for swing and senior -available for wet and dry grinding

Grinding Wheels ( Grinding Stone )'s first brand to be Mountain, has been approved by more than 15 years market experiences in most of quarry countries, especially Saudi Arabia ,

At present, Our exported Q'ty of Mountain Grinding Wheel consumption for Saudi granite quarry reach 10,000 pcs per year.

Technical sheet

| Hardness: the degree of difficulty of abrasive particles falling off the surface of abrasive tools during grinding. | |||||||||||||

| Super soft | soft | Medium soft | Middle | Medium hard | hard | Superhard | |||||||

| Super soft | soft 1 | soft 2 | soft 3 | Medium soft 1 | Medium soft 2 | Middle 1 | Middle 2 | Medium hard 1 | Medium hard 2 | Medium hard 3 | Hard 1 | Hard 2 | Superhard |

| D,E,F | G | H | J | K | L | M | N | P | Q | R | S | T | Y |

Major size for quarry grinding machine.

(1) B125*65* 31.75 GC 46K 30 m/s

(2) B200*25*31.75 GC 46 K 35m/s

(3) B150*65 *31.75 GC 46K 30 m/s

(1) 125 x 65 x 31.75mm 150 X65 x 31.75 mm spec:39g54-3l5vk Carbide Grinding Stone are used for 120 DC purpose.

(2) 200 X25X 31.75mm spec: 39g60m5vk Carbide Grinding Stone are used for jack hammer Integral drill stell and Chisel Bits sharpening purpose.

|

Images

|

Terms & Conditions of Ordering:

1 .Payment Terms:

T/T (Telegraphic Transfer) or Western Union

2. Delivery Term:

Based on order quantity, normally it takes 25 days for production.

Only 2 or 3 days if we have stock on your request size.

3. Transportation:

Sample order: we suggest Courier express or by air

Bulk order: we suggest by air or by sea.

4. Quality & Service:

A. There will be strict inspection and testing for every order before shipping out.

B Our sales team and Technical Support will response for your question within 24 hours (Holidays Excluded) through skype( simonhu6) and WhatsApp/Wechat: + 86 139 1110 7654

C. Free replacement will provide once the failure confirmed caused or our product quality; Not satisfied with a refund.