- Product Details

- {{item.text}}

Quick Details

-

Power:

-

80 W

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

7500 KG

-

Production Capacity:

-

Reqquirement

-

Brand:

-

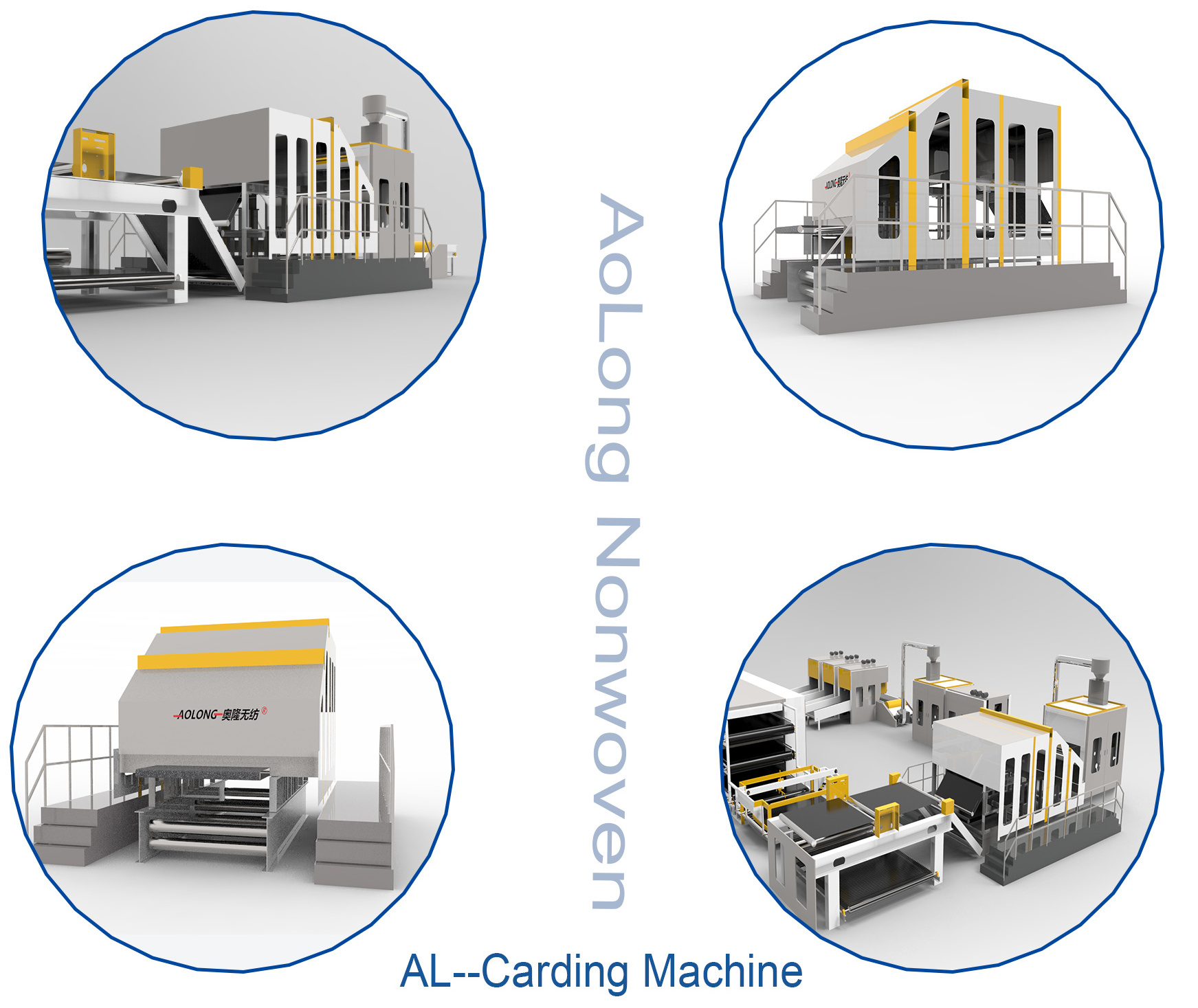

AOLONG(A.L)

-

Product name:

-

carpet machine nonwoven machine

-

Name:

-

Non woven machinery

-

Application:

-

exhibition ,outsaid door

-

Raw material:

-

Polypropylene Granules

-

Machine Type:

-

Needle punching ,carding machine

-

Product Width:

-

6000mm

-

capacity:

-

Customizable

-

Color:

-

Customzied

-

After Warranty Service:

-

Video technical support

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

AOLONG

-

Power:

-

80 W

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

7500 KG

-

Production Capacity:

-

Reqquirement

-

Brand:

-

AOLONG(A.L)

-

Product name:

-

carpet machine nonwoven machine

-

Name:

-

Non woven machinery

-

Application:

-

exhibition ,outsaid door

-

Raw material:

-

Polypropylene Granules

-

Machine Type:

-

Needle punching ,carding machine

-

Product Width:

-

6000mm

-

capacity:

-

Customizable

-

Color:

-

Customzied

-

After Warranty Service:

-

Video technical support

Product Overview

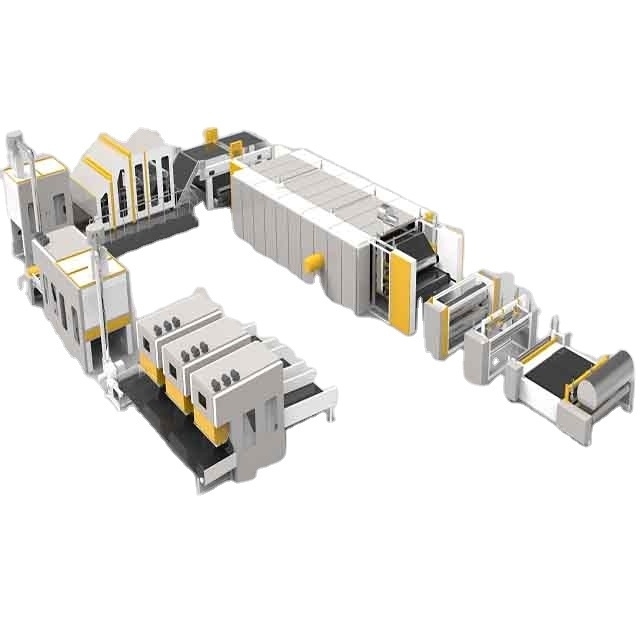

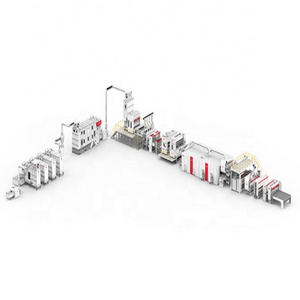

ALDT---6000mm Carpet Needle Punching Nonwoven Production Line

/non woven making machine

1:Working principle:Needle board drive the needles moving up and down frequency,teeth of the needles will drive the fibers interweave together,to be compact fabric;

:2:Main components:frame、main shaft、push rod、beam、needle board、circulation oil-way ect;

3:

Stripper and support board:10mm,adopts electric lifting,needle depth and gaps can be shown on the machine scale-plate and HMI;

4:

Beam:cast aluminum structure,light weight but can guarantee the high frequency;

5:

Needle destiny 6500pcs/m, random arrangement by computer, diaφ1.83mm, aluminum alloys needle beam,and aluminum magnesium alloy downward needle plate with bore-hole,single polyurethane plated,air locked needle plate.

6:

Frequency:Max=720r/min;

7:Speed:Max=10m/min;

7:Speed:Max=10m/min;

Detailed Images

|

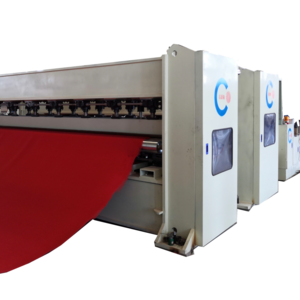

Final Products Name

|

Carpet Needle Punching nonwoven Production Line

|

|

machine width

|

6500mm

|

|

Production width

|

6000mm

|

|

Capacity

|

50--300kg/h based on 15D*51mm fiber

|

|

Raw material

|

PP fiber with 3D-20D 38mm--80mm

|

|

Electric control mode :

|

Control table or PLC

|

|

Power

|

Specified by customer

|

Working Process

Bale-opener→ Pre-opener →Big cabinet blender →Main opener→ Vibrating fiber Feeder →Double cylinder double doffer double random carding machine →Cross lapper →pre-needle punching →needle punching → needle punching→ needle punching → cutting &winding machine

Machine and product show

Our Company

DongYang AoLong Nonwoven Equipment co., Ltd. is a professional manufacturer Of PP spun bonded fabric production lines, PET needle punching production lines and special application treatment equipments like hydrophobic, antialcohol (blood, oil, static, aging,bacteria, UV) and fire retardant, which integrates project design processing.

we have completed numerous project in 13 years in different countries.We have our own exporting license with ISO and CE certificate.We have installed numbers of PP spunbond nonwoven fabric machine lines in China local market and India,Bangladesh, Turkey,Russia,Vietnam,U.A.E,Indonesia,Thailand,Brazil,Uzbekistan,South Africa etc.

we have completed numerous project in 13 years in different countries.We have our own exporting license with ISO and CE certificate.We have installed numbers of PP spunbond nonwoven fabric machine lines in China local market and India,Bangladesh, Turkey,Russia,Vietnam,U.A.E,Indonesia,Thailand,Brazil,Uzbekistan,South Africa etc.

Our Service

Why Choose AL NONWOVEN ?

1:When you encounter problems, or your equipment needs to be upgraded, we can provide you with the most energy-efficient and reasonable budget solution

2:If you are a novice in the market, we will provide you with the most professional consulting services and guidance according to your expectations.

Make sure you do a test or trial before shipment so that you can witness real-time production and make necessary adjustments according to your market needs.

3: If you are planning to Increase your production scale, Let us know your requirements ( Intended product, Capacity, Density and Raw material)

We avail you the Production layout of the new line for your reference

1:When you encounter problems, or your equipment needs to be upgraded, we can provide you with the most energy-efficient and reasonable budget solution

2:If you are a novice in the market, we will provide you with the most professional consulting services and guidance according to your expectations.

Make sure you do a test or trial before shipment so that you can witness real-time production and make necessary adjustments according to your market needs.

3: If you are planning to Increase your production scale, Let us know your requirements ( Intended product, Capacity, Density and Raw material)

We avail you the Production layout of the new line for your reference

Packing & Delivery

NUDE PACKING , WOODEN CASE IS OPTIONAL. CASE PACKING:CARDING MACHINE, LAPPER AND ELECTRIC BOXES WOODEN CASE PACKAGED.

OTHER MACHINES NUDE PACKAGING.

ANY DAMAGE IN TRANSPORT OF MACHINES IS NOT DUTY OF THE SELLER.

OTHER MACHINES NUDE PACKAGING.

ANY DAMAGE IN TRANSPORT OF MACHINES IS NOT DUTY OF THE SELLER.

FAQ

How do we place an order to start producing the machine and how to pack the machine?

1: We will adjust the machine according to your requirements, design drawings, or according to your plant size

2: We will design, produce, debug, and test the machine. Before packaging, we will send all your videos and photos for customers to check. After the machine is successfully tested, the machine will be separated for easy loading.

3: The spare parts are stored in a wooden box to avoid damage.

4: After each container is loaded, write down the detailed information of the machine and make a detailed description of the container, and then forward it to the customer for their reference.

1: We will adjust the machine according to your requirements, design drawings, or according to your plant size

2: We will design, produce, debug, and test the machine. Before packaging, we will send all your videos and photos for customers to check. After the machine is successfully tested, the machine will be separated for easy loading.

3: The spare parts are stored in a wooden box to avoid damage.

4: After each container is loaded, write down the detailed information of the machine and make a detailed description of the container, and then forward it to the customer for their reference.

Hot Searches