- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

smt glue dispenser

-

Dispensing Volume:

-

10-100g/5s(based on 1:1 glue proportion)

-

Dispensing Precision:

-

Glue Amount±1%, Glue Proportion±1%

-

X/Y/Z Working Range:

-

1000*1000*1000mm

-

XYZ Speed:

-

X/Y 450mm/s Z180mm/s

-

Repeatability:

-

±0.01mm

-

Input Pressure Range:

-

0.5-0.7MPa

-

Head Seal Pressure:

-

MAX≤2.6Mpa

-

Adhesive Viscosity:

-

<10000CPS

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZCX

-

Weight (KG):

-

400

-

Product name:

-

smt glue dispenser

-

Dispensing Volume:

-

10-100g/5s(based on 1:1 glue proportion)

-

Dispensing Precision:

-

Glue Amount±1%, Glue Proportion±1%

-

X/Y/Z Working Range:

-

1000*1000*1000mm

-

XYZ Speed:

-

X/Y 450mm/s Z180mm/s

-

Repeatability:

-

±0.01mm

-

Input Pressure Range:

-

0.5-0.7MPa

-

Head Seal Pressure:

-

MAX≤2.6Mpa

-

Adhesive Viscosity:

-

<10000CPS

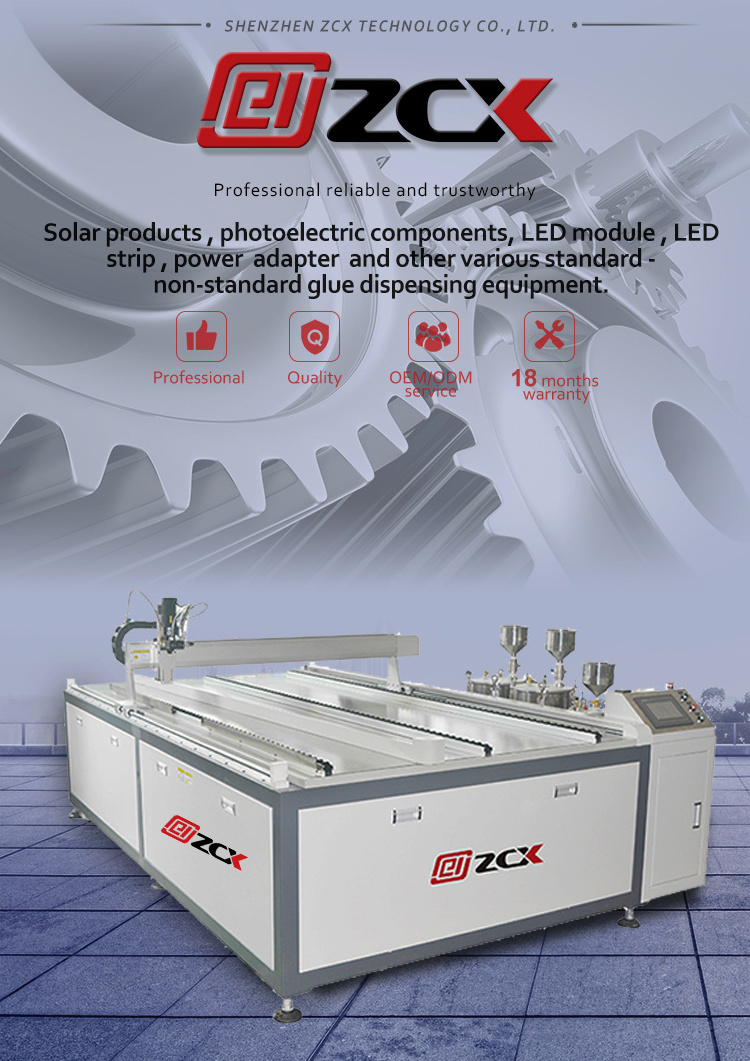

Thank you for visiting us, Best smt glue dispenser customization service will provide to you.

| Floor type 2 components glue dispensing machine smt glue dispenser | |||||||

| Model | PJ180 | SZ700 | SZ1000 | SZ1500 | SZ2400 | ZD5000 | |

| Axis(mm) | X | 700 | 1000 | 1000 | 1200 | 700 | |

| Y | 700 | 1000 | 1500 | 2400 | 5000 | ||

| Z | 100 | 100 | 100 | 100 | 100 | ||

| Dimension(mm) | L | 1050 | 1520 | 1765 | 1765 | 2015 | 6100 |

| W | 850 | 1150 | 1350 | 2050 | 2870 | 1180 | |

| H | 1500 | 1350 | 1350 | 1400 | 1350 | 1500 | |

| Weight(kg) | 255 | 350 | 400 | 450 | 600 | 1000 | |

| Package volum(CBM) | 1.2 | 3.5 | 4.5 | 5.5 | 9 | 12 | |

| Rated power consumption | 380/220/110V 50/60Hz 900W (Optional) | ...2000W | |||||

| Moving Speed | 300mm/s(Max 500mm/s not suggested) | ||||||

| Moving Precise | ±0.05mm | ||||||

| Moving Path | Point, line, square, circle, arc,dome | ||||||

| Glue mixing ratio | 1:1~10:1 | ||||||

| Potting Speed | 10-150g/5s(Adjustable) | ||||||

| Potting Precise | Amount±1%, Ratio:±1% | ||||||

| Air Pressure | 0.5-0.8MPa | ||||||

| Head Sealing pressure | MAX≤2.6Mpa | ||||||

| Glue water viscosity | <10000CPS(inquiry for above) | ||||||

| Operation Method | Auto, Manual | ||||||

| Program Method | Teaching Program | ||||||

| Electronic Control System |

Smart control card+PLC+Touch Screen

(Program setting, modify, save) |

||||||

| Glue Stop System | A, B Glue independent movement auto resorption system | ||||||

| Mixing Stirring System | High speed dynamic stirring mixing device(static option) | ||||||

| Glue ratio control | High precise metering pump | ||||||

| A,B glue supply system | A | High precise gear/screw pump 6-12CC |

Bucket

stirring optional |

Heating

optional |

20-50L

Customizable |

Vacuumable | |

| B | High precise pressure gear/screw pump 0.6-2.4CC | ||||||

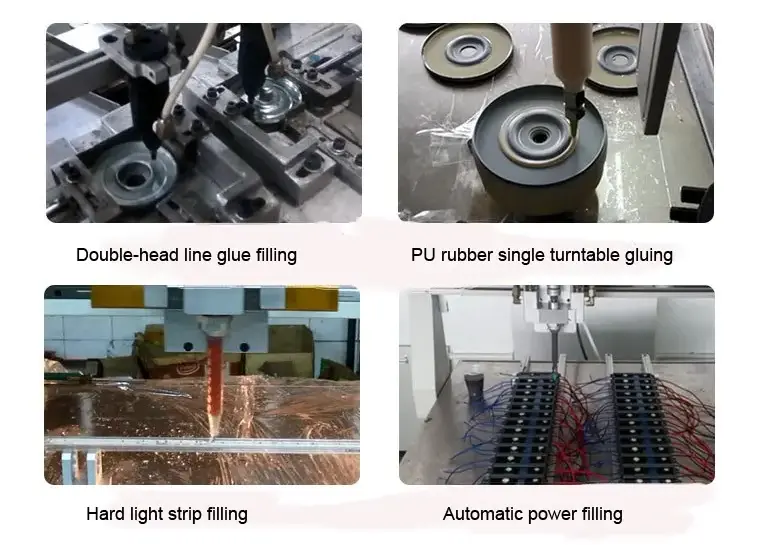

This glue dispensing&coating machine is suitable for high efficiency, high operation precision, high glue proportion production process; mainly used in : crafts, label signs, wall stickers, electronic products and other industries glue dispensing process .

Main features:

- Two component A&B glue high pressure supply system and metering dispensing system with high precision and automatic identification and positioning functions;

- High precision grinding grade wcrew rod,slider,rail,and Mitsubishi servo motor,Top grade materials,

- Adopt professional industrial control PLC/PC computer system, original motor, electronic components, wiring, dustproof, anti-static system are designed according t o national standards.

- English interface provided and easy operate easy maintain.

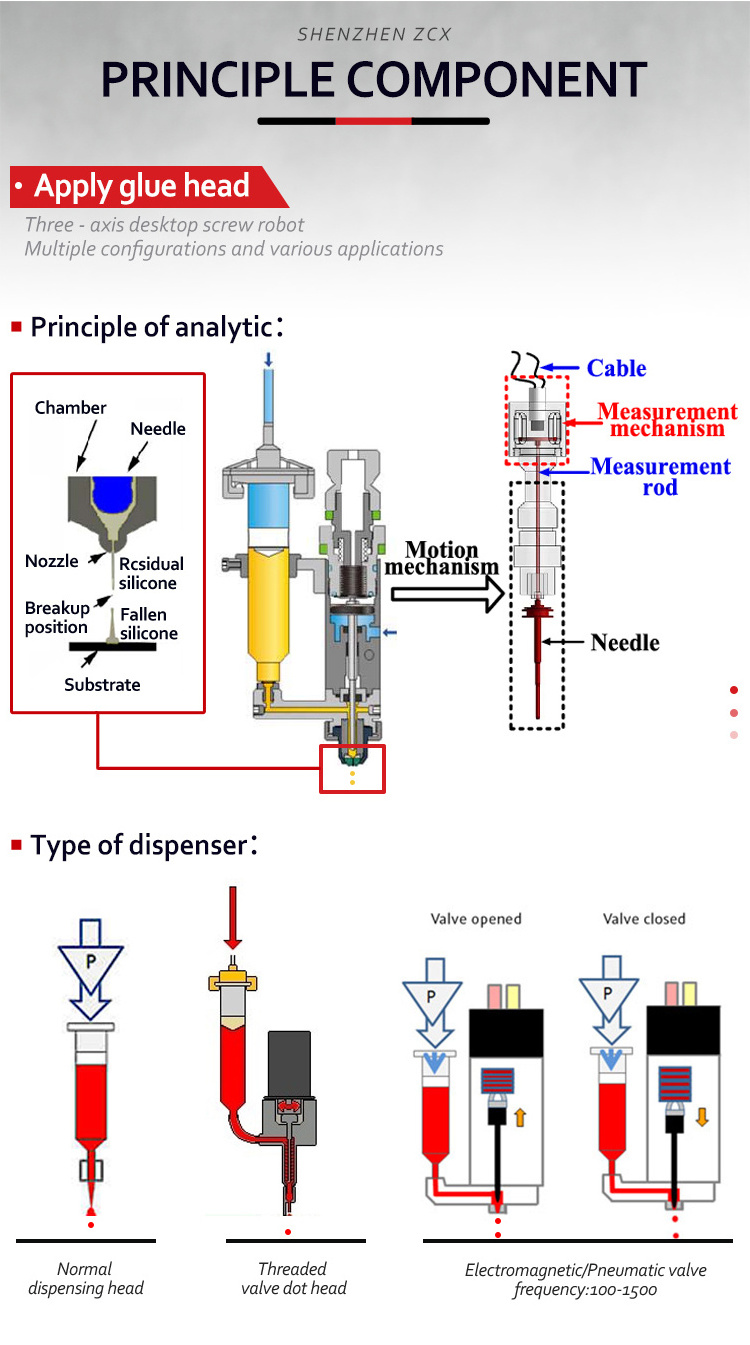

Dispensing valve principle&structure:

There are variaty of configurations for different technique processing. Different glue and glue ratio , substrate,surface, program or dispensing type may effect on the configurations of the machine.

So provide glue TDS to us is important.

- Plenty options of configurations

- Fit for various of glue

- Match for most of processing of production

We have well experienced sales man, please do not hesitate to tell him your requirments, they will provide you the best solution right now!

We have owned industry park and full process of hardware&software R&D department.provide one station service of automatic production process facilities.

- Talk with our sales man and will get your full requirments;Our engineer will design and creat the solution with engineering drawing;

- After confired, we will start to preare all stuff of the machine,

- Assembly by another department will be the third step;

- Debug and test will be a very important step,make sure the machine working well before ship;

- For sea transportation, the machine will be vacuum packed and waterproof to make sure arrives safe in long distance ship.

Customers satisfy is the most important for us! From our engineers to the assembly workers, we are clearly that only the best product and service brings long run relationship!

You will have no worries to work with a professional manufacture who have 10 years of experience of customization service.

Over ten years of development, plenty of customized solution provided, we are well expericed in all process in automation industry.

And customers are satisfied with our products and service.This also is the vision of our company.Temp up with us to build more and more win-win relationship.

- We provide 18 month ultra long tern warranty.

- Lifetime technique service and spareparts supply service.

- For big machine,we provide onsite installation and training service.

Happy work and happy life, we are ready for service you!