- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Apartment

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

UETERSEN

-

Model Number:

-

UT-GWA4850

-

Function:

-

thermal and sound insulation

-

Applications:

-

indoor sound insulation

-

thermal conductivity:

-

<0.037W/m.K

-

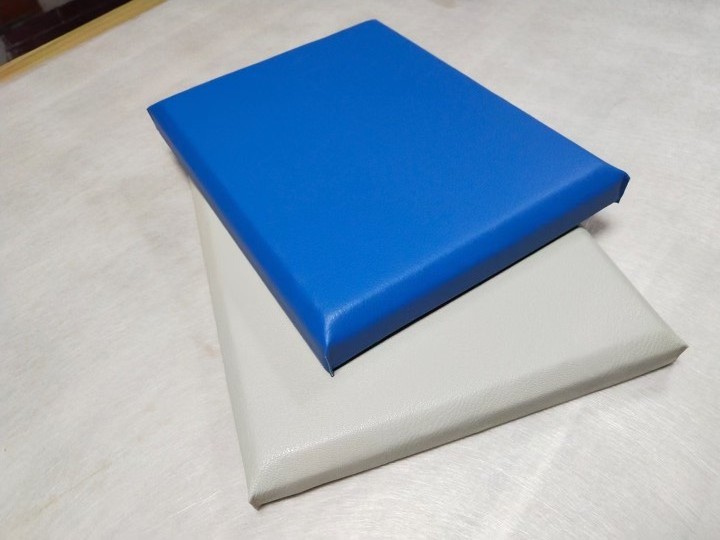

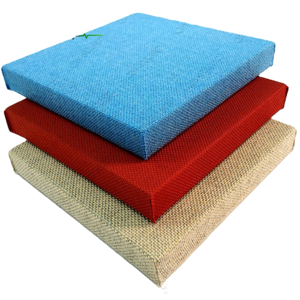

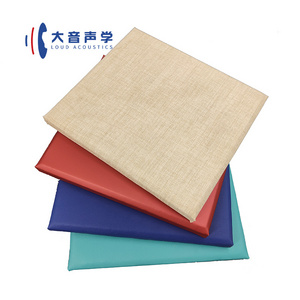

color:

-

yellow, white

-

Density:

-

32-80kg/m3

-

Core Material:

-

fiberglass

-

Thickness:

-

25, 50,75,100mm

-

Width:

-

400/600/1200mm

-

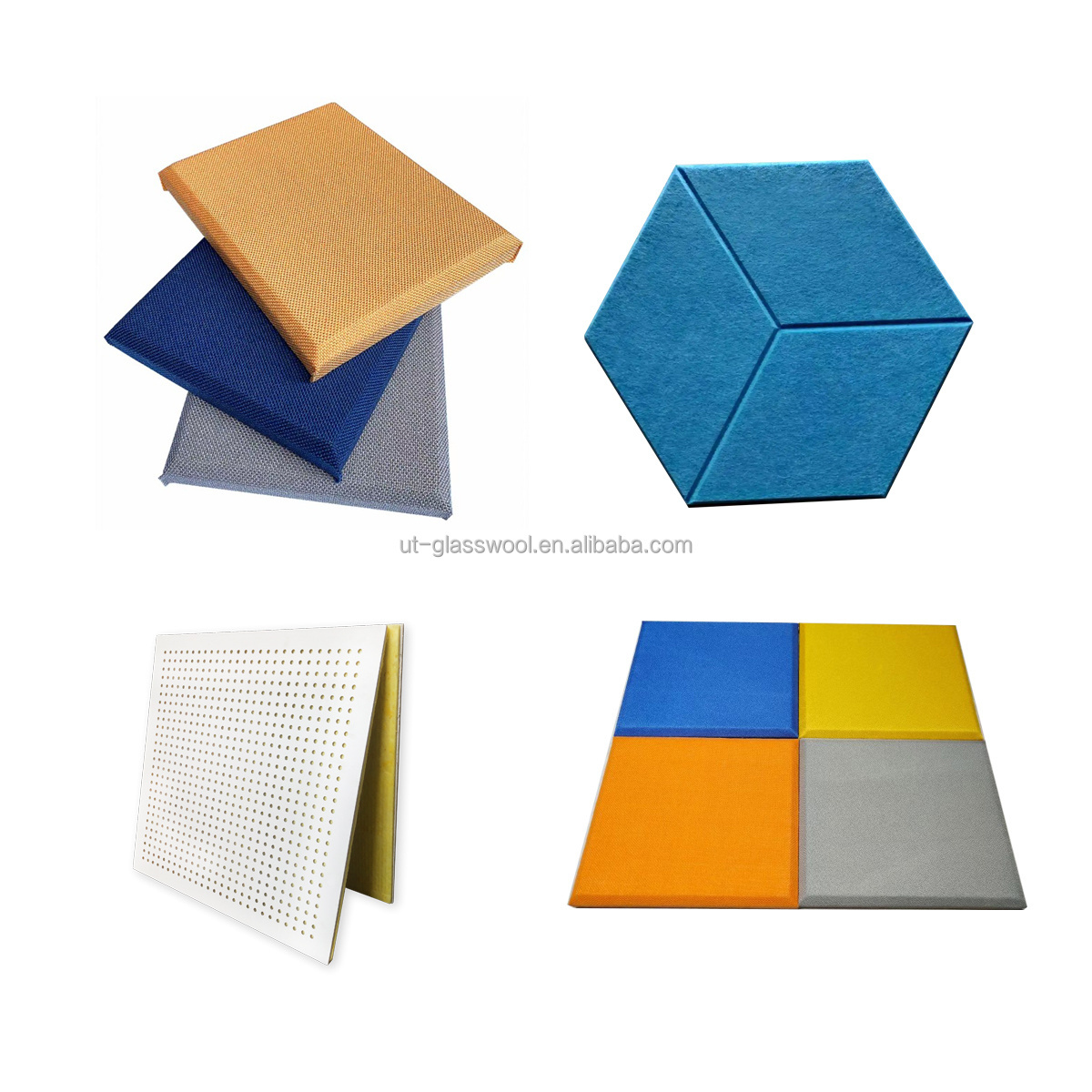

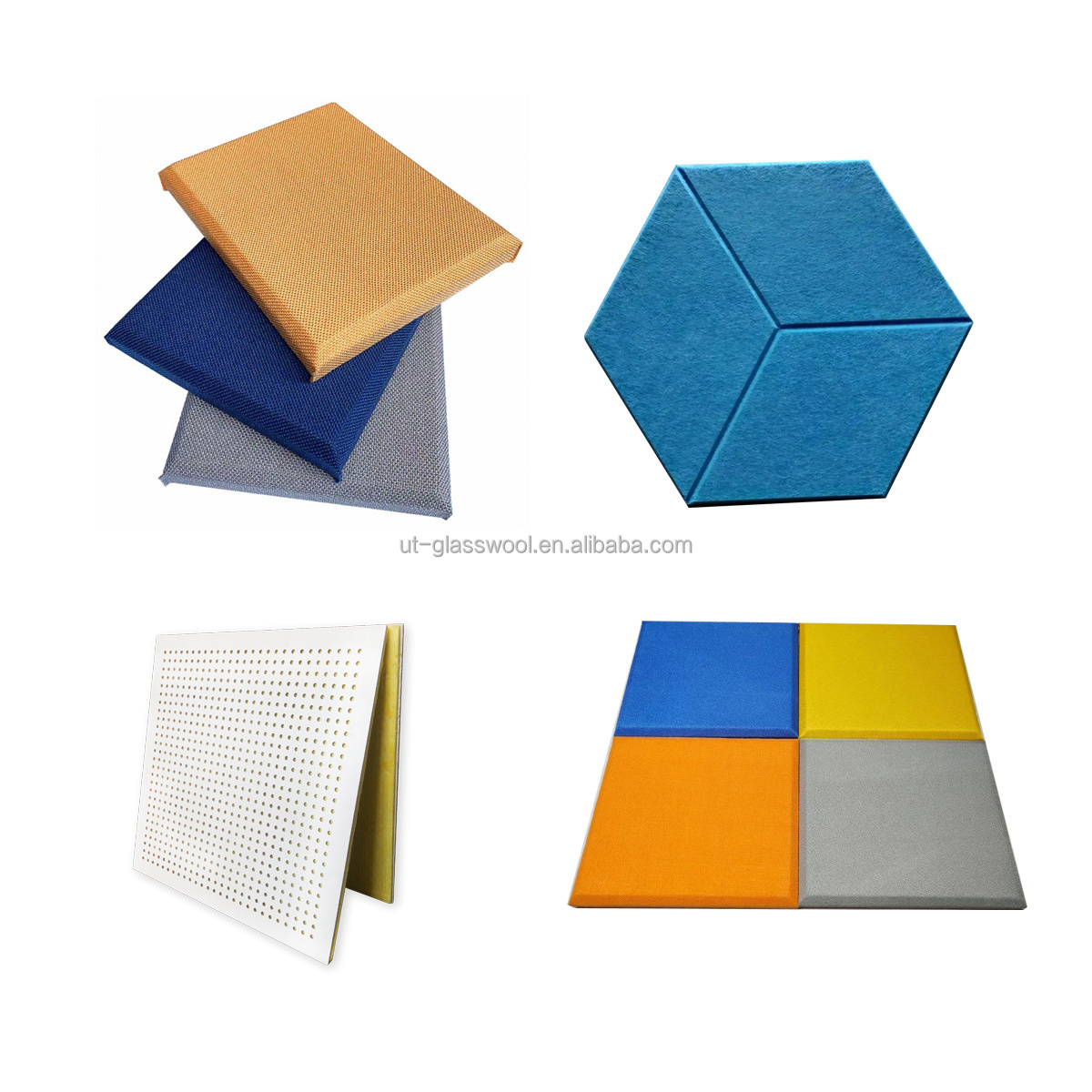

shape:

-

rectangle, hexagon, etc.

-

Facing:

-

fabric fiber membrane

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Apartment

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

UETERSEN

-

Model Number:

-

UT-GWA4850

-

Function:

-

thermal and sound insulation

-

Applications:

-

indoor sound insulation

-

thermal conductivity:

-

<0.037W/m.K

-

color:

-

yellow, white

-

Density:

-

32-80kg/m3

-

Core Material:

-

fiberglass

-

Thickness:

-

25, 50,75,100mm

-

Width:

-

400/600/1200mm

-

shape:

-

rectangle, hexagon, etc.

-

Facing:

-

fabric fiber membrane

Glass wool is good sound insulation material natually, for acoustic application, Uetersen glass wool board is smooth processed by means of polish on both sides, and then face with microns fiber mambrane. The main purpose of these process is to improve its flatness and spalling resistance.

Uetersen is expertise in room acoustic design as well. So we understand what product properties should be valued in specific applications. Our acoustic panels can be shaped as differenct geomerty and dimensions, wrapped by different membrane in different colors.

Further more, if any client is interested in set up plant to process acoustic board locally, we are very glad to provide related materials and technical couslutance.

Glass wool insulation quality rely on fibres quality. Uetersen glass fibers have the features as following:

- Uniform long and fine fibers, diameter is less than 7 microns, length is 15-20cm.

- High strength fibers, soft and no shots content.

- Binders and additives are sprayed evenly

- No hazardous substance contained, formaldehyde-free optional, etc.

What effect the glass wool quality?

- Raw materials: high level impurity substance will cause fibres quality directly and cause high shot content. On the other hand, in order to avoid unhealty elements, additives or binders should come from those qualified brands.

- Formula: A proper formula can generate fine fibers with high tensile strength .

- Production equipments and operation: The temperature control, spinning speed, feeding volume,etc. these factors will effect the fibers diameter thus furtherly effect its insulation performance.

- QC: if QC absent at some vital production steps. it can be imaged how disastrous the final products is.

Applications

Uetersen is a time-honored brand of thermal insulation materials manufacturer. With decades of development, Uetersen gathers strong R&D capability and sophisticated manufacturing skills. In China, we are in lead to launch high-end thermal insulation materials, such as aerogel insulation panels, Vacuum Insulation panels, formaldehyde-free glass wool, LNG resilient blanket, etc. More than a manufacturer, we are also expertise in complete solutions in the field of building thermal insulation, room acoustic, industrial duct insulation, LNG tank insulation, etc. So, let's talk about your projects, we are standby to serve you individually.

Most of our rock wool and glass wool insulation materials are packed into PE bag/film, shrinkage and vacuumed, then put into another woven bag or kraft carton. We will make sure they are in minimum dimension and good conditions enough for long distance delivery by sea, by land, or by air.

A1:Uetersen has been in the thermal insulation industry for more than 20 years. Some of our management members have been in this field since the first rock wool plant was set up in China. With such rich experience, we can provide unmatched consulting service to make sure that you will get the right thermal insulation materials which can cover your requests and related standards. In addition, Uetersen keeps increased research-input to update the latest technologies to meet gradually tougher requirements in different applications.

Q2: What products Uetersen can manufacture?

A2: We have 4 focused divisions to meet your requirements principally, Rock wool, Glass wool, Rubber foam, as well as aerogel. But those materials derive a variety of properties to cover specific requirements.

Q3: Are you accept OEM/ODM order?

A3: We surely provide customer-tailored service. But a corresponding production quantity is required to lower the average cost, which you can well understand.

Q4: How about the lead time?

A4: We usually keep certain amount of common models in our warehouse. We can make fast delivery for small orders after final inspection and packaging. Whilst for those orders come with excessive quantity or customized production, we usually make delivery in 10-30 working days accordingly.