- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±2ml

-

Voltage:

-

380V/220V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LINKS

-

Dimension(L*W*H):

-

4250X2150X2200mm

-

Weight:

-

5200 KG

-

Bottle Size:

-

150ml to 2000ml

-

Bottle Neck Diameter:

-

15-55mm

-

Bottle Material:

-

Plastic/Glass

-

Control System:

-

PLC Touch Screen(MITSUBISHI JAPAN)

-

Filling Liquid Temperature:

-

0-4 Degree

Quick Details

-

Machinery Capacity:

-

8000BPH, 12000BPH, 6000BPH, 2000BPH

-

Packaging Material:

-

Glass, Plastic

-

Filling Material:

-

Water, Juice, carbonated water

-

Filling Accuracy:

-

±2ml

-

Voltage:

-

380V/220V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LINKS

-

Dimension(L*W*H):

-

4250X2150X2200mm

-

Weight:

-

5200 KG

-

Bottle Size:

-

150ml to 2000ml

-

Bottle Neck Diameter:

-

15-55mm

-

Bottle Material:

-

Plastic/Glass

-

Control System:

-

PLC Touch Screen(MITSUBISHI JAPAN)

-

Filling Liquid Temperature:

-

0-4 Degree

Products Description

High Quality Carbonated Beverage Filling Line For PET Bottle Or Glass Bottle

*We supply complete solution for the Carbonated beverage filling plant ,including Water treatment system / Carbonated beverage mixing system / Washing filling capping machine / Code sprayer / Pasteurizer tunnel / Automatic labeling machine / Automatic packing machine / Automatic Palletizer system

|

Technical parameter : carbonated beverage filling machine

|

|

|

|

|

|

|

||||||

|

Model

|

DCGF14-12-5

|

DCGF16-16-5

|

DCGF18-18-6

|

DCGF24-24-6

|

DCGF32-32-8

|

DCGF40-40-10

|

||||||

|

Capacity(for 500ml)

|

2000-3000

|

3000-4000

|

3000-5000

|

6000-8000

|

8000-12000

|

12000-15000

|

||||||

|

Suitable bottle shapes

|

PET circular or square

|

|

|

|

|

|

||||||

|

Bottle diameter(mm)

|

Dia50-Dia115mm

|

|

|

|

|

|

||||||

|

Bottle height (mm)

|

160-320mm

|

|

|

|

|

|

||||||

|

Compressor air

|

0.3-0.7Mpa

|

|

|

|

|

|

||||||

|

Washing meidium

|

Aseptic water

|

|

|

|

|

|

||||||

|

Rinsing pressure

|

>0.06Mpa <0.2Mpa

|

|

|

|

|

|

||||||

|

Application

|

Carbonated drink filling machine

|

|

|

|

|

|

||||||

|

Total power (KW)

|

4.4kw

|

4.4kw

|

5.2kw

|

6.2kw

|

7.5kw

|

8.2kw

|

||||||

|

Overall dimensions

|

2.5*1.9m

|

2.7*1.9m

|

2.8*2.15m

|

3.1*2.5m

|

3.8*2.8m

|

4.5*3.3m

|

||||||

|

Height

|

2.3m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

2.6m

|

||||||

|

Weight(kg)

|

3000kg

|

4000kg

|

4500kg

|

6000kg

|

8500kg

|

10000kg

|

||||||

Different filling capacities

DCGF14-12-5 Bottle Carbonated beverage Filling Line Capacity:1500-2000 bottles per hour.

DCGF18-18-6 Bottle Carbonated beverage Filling Line Capacity:3000-5000 bottles per hour.

DCGF24-24-8 Bottle Carbonated beverage Filling Line Capacity:50000-7000 bottles per hour.

DCGF32-32-10 Bottle Carbonated beverage Filling Line Capacity:8000-10000 bottles per hour.

DCGF40-40-12 Bottle Carbonated beverage Filling Line Capacity:12000-15000 bottles per hour

DCGF50-50-15 Bottle Carbonated beverage Filling Line Capacity:16000-20000 bottles per hour

DCGF18-18-6 Bottle Carbonated beverage Filling Line Capacity:3000-5000 bottles per hour.

DCGF24-24-8 Bottle Carbonated beverage Filling Line Capacity:50000-7000 bottles per hour.

DCGF32-32-10 Bottle Carbonated beverage Filling Line Capacity:8000-10000 bottles per hour.

DCGF40-40-12 Bottle Carbonated beverage Filling Line Capacity:12000-15000 bottles per hour

DCGF50-50-15 Bottle Carbonated beverage Filling Line Capacity:16000-20000 bottles per hour

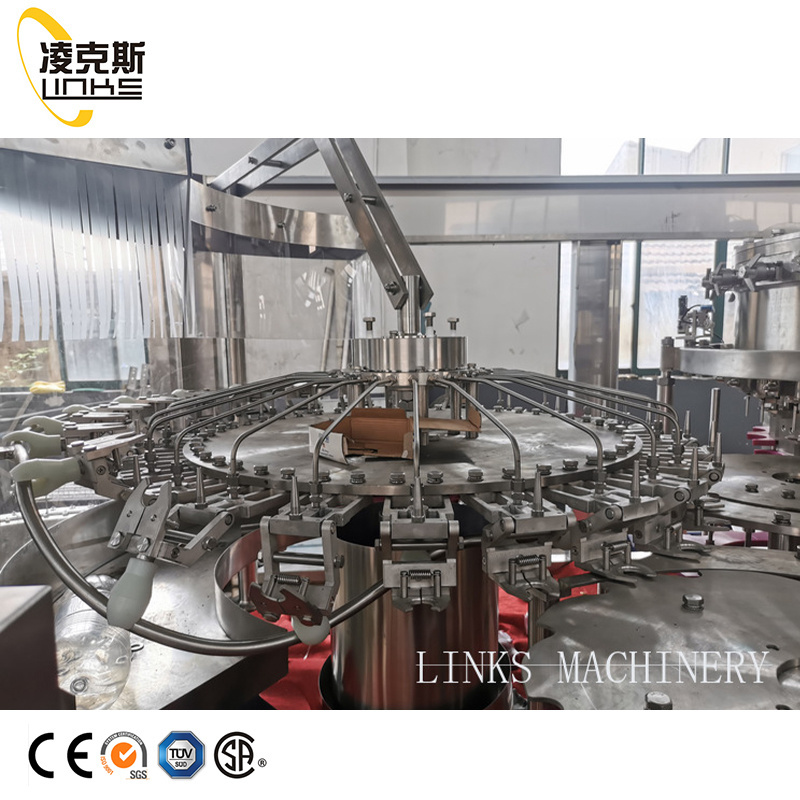

Details Images

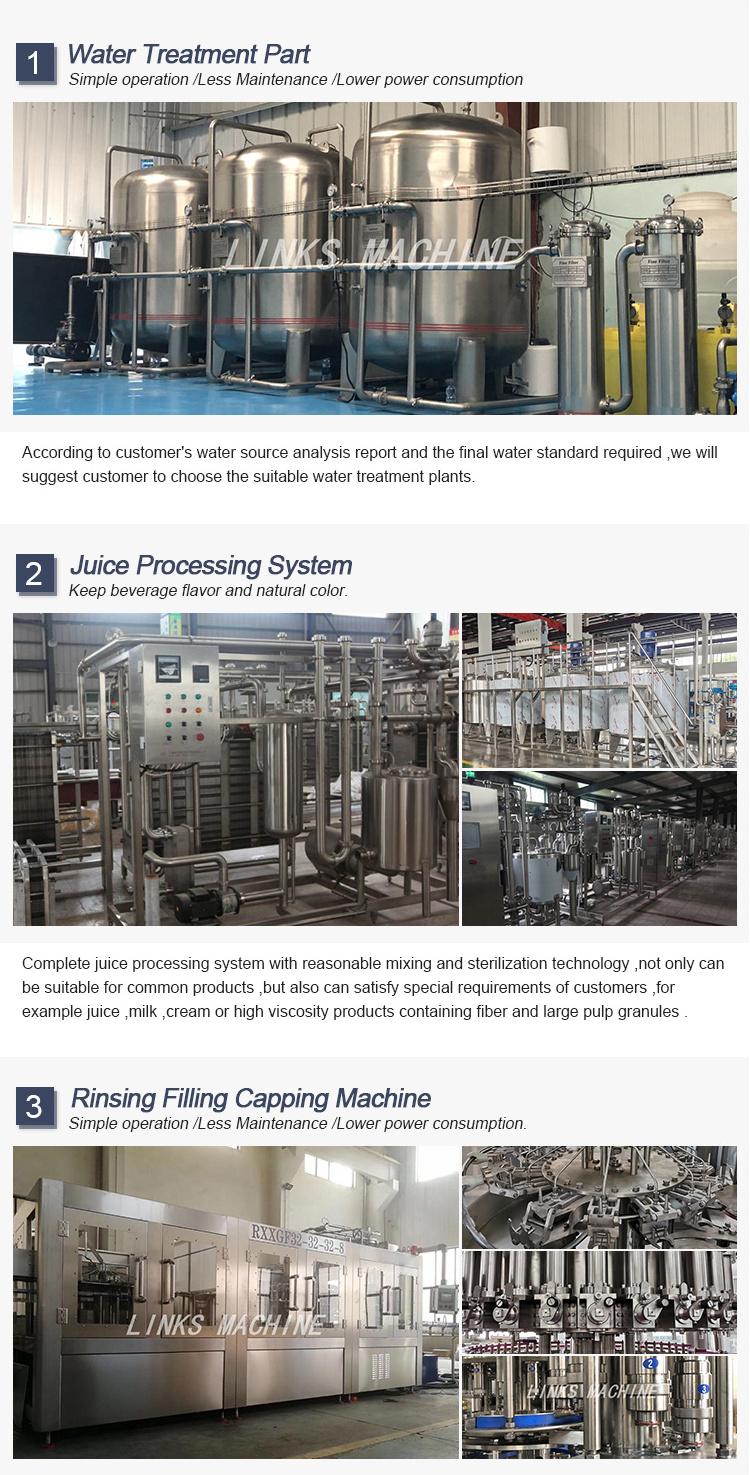

According to customer's water source analysis report and the final water standard required ,we will suggest customer to choose the suitable water treatment plants.

Carbonated beverage mixing system structure reasonable, =mix precision is high, CO2 mixes fully, has two times of cooling, two carbonation merits. Mainly is suitable for kinds of carbonated drink's mix processing, also may use in the paste drink, the fermentation drink and so on other soft drinks' mix processing.

Main Features

*Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

* Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

* The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

*High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid loss.

*Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

*Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

|

Name

|

Brand

|

Area

|

|

PLC

|

Siemens

|

Germany

|

|

Inverter

|

Siemens

|

Germany

|

|

Contactor

|

Siemens

|

Germany

|

|

Touch screen

|

Siemens

|

Germany

|

|

Inverter

|

Siemens

|

Germany

|

|

Motor

|

ABB

|

Swiss

|

|

Pneumatic parts

|

FESTO

|

Germany

|

|

Electrical parts

|

Schneider

|

France

|

As customer request and market demand, we provide the better solution for the final product package,We have various kinds of options. Labeling machine have the PVC sleeve label, BOPP hot glue label, Adhesive stick label, Wet glue label ,and packing machine have the film shrink machine and carton box package.

We design the factory layout based on customer factory sizes,whole line design is based on famous brand motors and automatic lubricant system ,and with less power consumption ,and save space .

This machine is a fully automatic, high intelligent, stable and reliable blowing machine, with simple structure, and low energy consumption. It is very popular and well used in food, beverages, cosmetics, pharmaceutical industry.

Turnkey Solution

Leadership in quality and technology from raw material to bottled liquid to selling products - Links Co.,Ltd, A-Z turnkey plant supplier, is known for developing innovative high-end products and new technologies.

Hot Searches