- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Allraise

-

Weight:

-

350 KG

-

Dimension(L*W*H):

-

150*125*140cm

-

Model:

-

ORSG-1000

-

Maximum Board Size:

-

600*1000mm

-

Minimum Board Size:

-

50*55mm

-

Patch or Patch Edge Size:

-

0-450mm

-

Cardboard Thickness:

-

1-3mm

-

Total Power Supply:

-

2KW, 220V

-

Machine Pressure:

-

0.6-0.8MPa

-

Heating Tube Power:

-

800W

-

Overall Dimension:

-

150*125*140cm

-

Total Weight:

-

350kg

Quick Details

-

Voltage:

-

220v

-

Power:

-

2kw

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Allraise

-

Weight:

-

350 KG

-

Dimension(L*W*H):

-

150*125*140cm

-

Model:

-

ORSG-1000

-

Maximum Board Size:

-

600*1000mm

-

Minimum Board Size:

-

50*55mm

-

Patch or Patch Edge Size:

-

0-450mm

-

Cardboard Thickness:

-

1-3mm

-

Total Power Supply:

-

2KW, 220V

-

Machine Pressure:

-

0.6-0.8MPa

-

Heating Tube Power:

-

800W

-

Overall Dimension:

-

150*125*140cm

-

Total Weight:

-

350kg

Products Description

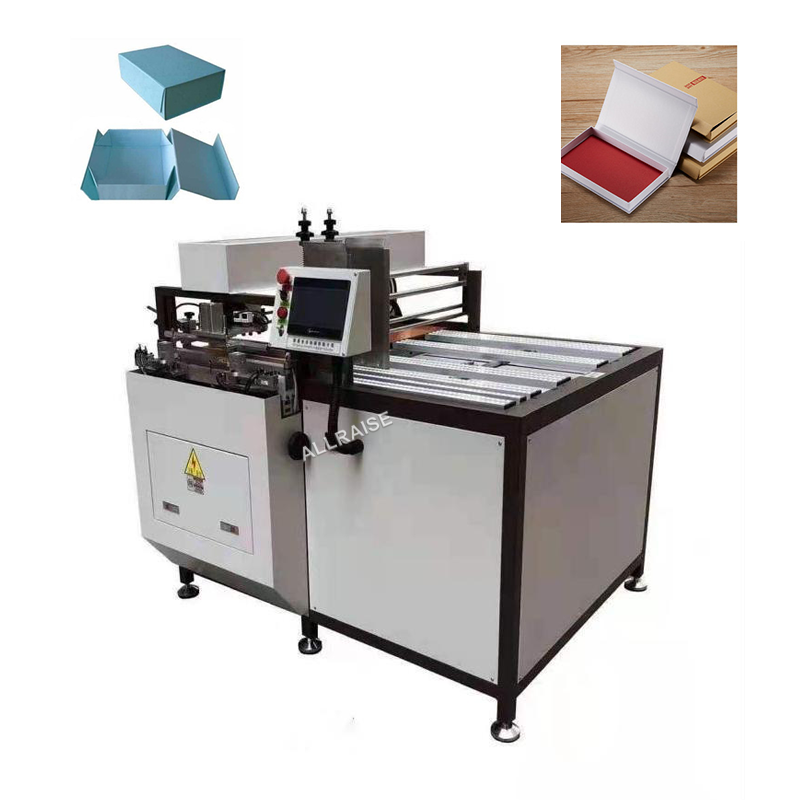

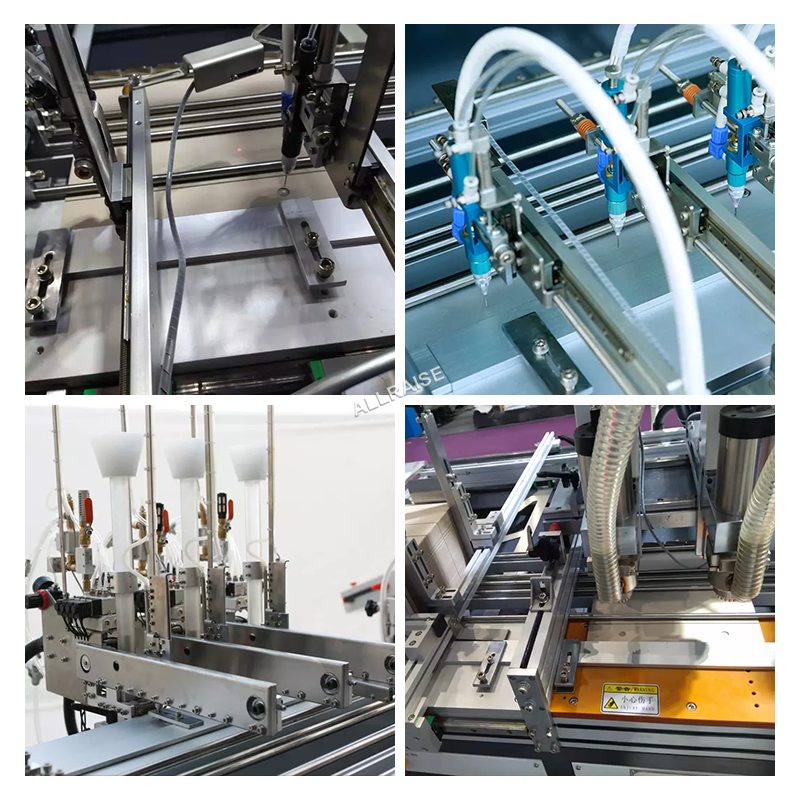

Gold Supplier Competitive Price Automatic Rigid Box Magnet Pasting Machine Magnet Button Machine

Automatic more stable and efficient magnetic magnet button pasting machine magnet inserting machine

|

Model

|

ORSG-1000

|

|

Maximum Board Size

|

600*1000mm

|

|

Minimum Board Size

|

50*55mm

|

|

Patch or Patch Edge Size

|

0-450mm

|

|

Patch or Patch Spacing Dimensions (Common Mode)

|

50-500mm

|

|

Patch or Patch Spacing Dimensions (Dislocation Mode)

|

0-500mm

|

|

Sticking Round Magnet Iron Sheet Size

|

φ6-φ20mm

|

|

Sticking Square Magnet Iron Sheet Size

|

8*10-15*20

|

|

The Highest Position Placing the Patch

|

240mm

|

|

The Highest Position Placing the Magnet

|

350mm

|

|

Placement Cardboard Height

|

400mm(Non-stop feeding matetrial)

|

|

Cardboard Thickness

|

1-3mm

|

|

Total Power Supply

|

2KW, 220V

|

|

Machine Pressure

|

0.6-0.8MPa

|

|

Heating Tube Power

|

800W

|

|

Glue Material

|

Hot Melt Adhesive

|

|

Total Weight

|

350kg

|

|

Overall Dimension

|

150*125*140cm

|

|

1

|

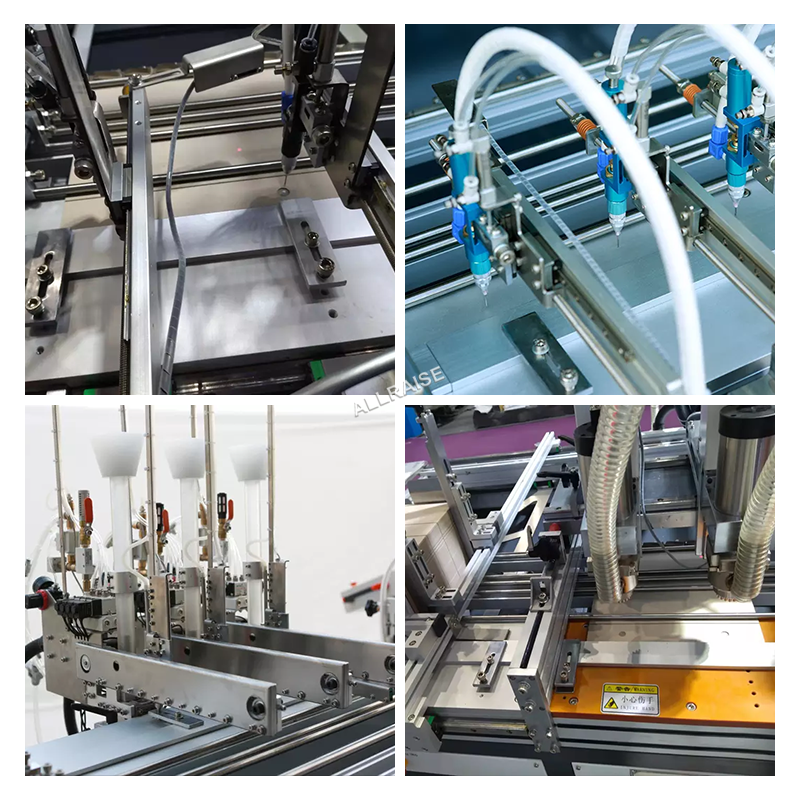

The design concept of this machine comes from simple automation, with the advantages of

simple operation, convenient maintenance, easy to learn and understand, easy operation by a single person, super labor saving and so on

.

|

|

2

|

The frame of the machine adopts combined design to make the body more stable and efficient.

PLC, stepper motor and touch screen are adopted for electrification to realize automatic operation, long service life and accurate magnetic patch.

|

|

3

|

The simple automatic multifunctional magnet laminating machine uses the working mode of formation type, with multiple dislocation paste function, to achieve the seamless docking of magnetic or patch spacing size, arbitrary adjustment.

|

|

4

|

It uses automatic workflow, automatic push paperboard, automatic magnetic suction iron sheet adhesive, automatic magnetic patch, automatic pickup paperboard and so on to complete the action.

|

|

5

|

Through the automatic feeding of the procession of the propulsion device, it can realize the feeding without stopping, with strong durability, non-stop work and high efficiency.

|

Related Products

Contact us

Tel/Whats App/Wechat: +86 18939255195

Package&Shipping

|

Packaging

|

By container or standard export packing per machine

|

|

Delivery time

|

15-30 days after payment received

|

Hot Searches