For more heavy-duty applications such as shredding cars, a hammermill is often the preferred choice. In situations where versatility,minimal noise and dust are a priority, a twin-shaft shredder may be the optimal solution for effectively processing a wide range of waste materials.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HX

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1400*600*1400

-

Power (kW):

-

5.5

-

Weight (T):

-

1.6

-

Name:

-

plastic shredder

-

Application:

-

Recycle Waste Plastic

-

Keyword:

-

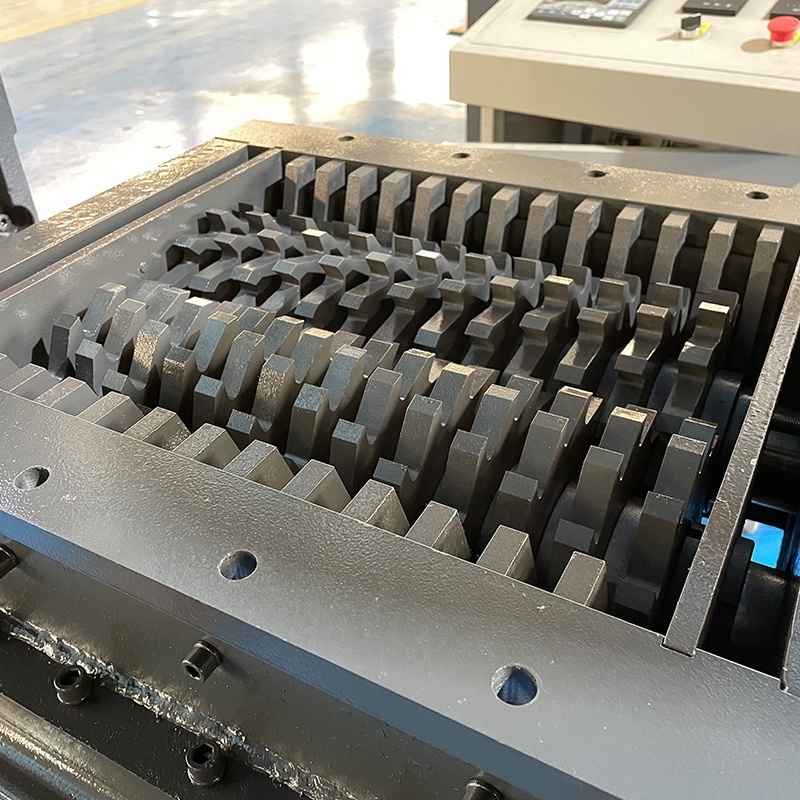

Two Shaft Plastic Shredder

-

Usage:

-

Waste Plastic Shredding

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Product name:

-

Shreddder Machine

-

Type:

-

Powerful Plastic Shredder

-

Crushing material:

-

General Plastic Materials

-

Motor:

-

3-45KW

-

MOQ:

-

1set

Quick Details

-

Max.Production Capacity (kg/h):

-

1000

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

800 - 1000 kg/h

-

Brand Name:

-

HX

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1400*600*1400

-

Power (kW):

-

5.5

-

Weight (T):

-

1.6

-

Name:

-

plastic shredder

-

Application:

-

Recycle Waste Plastic

-

Keyword:

-

Two Shaft Plastic Shredder

-

Usage:

-

Waste Plastic Shredding

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Product name:

-

Shreddder Machine

-

Type:

-

Powerful Plastic Shredder

-

Crushing material:

-

General Plastic Materials

-

Motor:

-

3-45KW

-

MOQ:

-

1set

How to Choose an Industrial Shredder For Your Business

INDUSTRIAL SHREDDERS

Pro-shred manufactures a wide variety of industrial shredders. Our versatile shredders can handle a wide variety of

materials including plastic, wood, fiberglass and many many more. Our shredding experts can help you select the right shredder for your application.

materials including plastic, wood, fiberglass and many many more. Our shredding experts can help you select the right shredder for your application.

SELECTING THE RIGHT SHREDDER

1. Type of Material to be Processed

When it comes to shredding various materials, it is essential to use the right type of shredder to achieve optimal results. For instance, a high-speed chipper is ideal for shredding tree branches, while a granulator (rotary knife cutter) is best suited for processing plastics. However, for bulky plastic shapes, a shredder can be used as a first stage before granulation.

2. Desired Output

Understanding the output size requirement will help in determining the type of equipment to install. Some facilities require the material to be separated, whereas others may need re-shredding and grinding. A single-pass shredder will cost less but if the material needs to be reduced to a very small size and compressed then compaction equipment may be required.

3. Capacity

Choosing an industrial shredder to handle the correct capacity is important to the success of any installation. Capacity is typically expressed in pounds per hour and is determined by the physical size, weight (bulk density), and the amount of material to be shredded. The capacity may be limited by the cutting chamber size. Check the capacity rating carefully before purchasing the machine and allow for some excess capacity. Using a shredder with a maximum capacity too close to the desired capacity can lead to a shortened service life. However, over-sizing a shredder by a wide margin can lead to excessive power use and take up too much floor space.

4. Feed Type

Two basic feed types are common: manual and automatic. Manually fed shredders usually have a hopper and work by either hand feeding the material or using a fork lift to drop the material in. Automatic feeders or conveyors help optimize shredder performance by giving a constant and regular supply of materials to the shredder.

5. Operational Considerations

Portability, safety, and noise are concerns when selecting a shredder. Select the proper location for the shredder because it is not easy to move a machine weighing a half ton or more. Depending on the material, dust and other airborne particles can be an environmental hazard. Noise is another factor to consider as some shredders (such as hammermills) create more noise than others.

6. Maintenance

Shredders endure a great deal of stress and maintenance is necessary to keep them running efficiently. Cutters, blades, or hammers will wear under normal use and require sharpening, adjusting, or eventually replacing. Consider maintenance, repairs, and ease of obtaining replacement parts when choosing a manufacturer. Always evaluate the access location for maintenance when determining where to locate any equipment including your shredder.

Product Paramenters

|

Model

|

Motor

|

Capacity(kg/h)

|

Blade size(mm)

|

Size of crushing chamber(mm)

|

Weight(t)

|

|

HX-600

|

37KW

|

600-800

|

260x30

|

600*400

|

2.2

|

|

HX-800

|

44KW

|

800-1500

|

260x40

|

800*600

|

5.6

|

|

HX-1000

|

74KW

|

1500-2000

|

360x50

|

1000*750

|

7.2

|

|

HX-1200

|

90KW

|

3000-5000

|

400x40

|

1200*800

|

8.8

|

|

HX-1400

|

110KW

|

5000-8000

|

500x40

|

1400*1000

|

13

|

|

HX-1500

|

150KW

|

10000-12000

|

560x50

|

1500*1100

|

15

|

|

HX-1600

|

180KW

|

14000-15000

|

560x60

|

1600*1200

|

18

|

|

HX-1800

|

220KW

|

15000-20000

|

600x80

|

1800*1200

|

22

|

|

HX-2000

|

264KW

|

20000-30000

|

650x80

|

2000*1400

|

28

|

Why Choose Us

There are several important factors to consider when selecting a suitable shredder. To expedite the matching process of equipment to your specific requirements, it is essential to gather all necessary information and compare it against the shredders' specifications. Before engaging in recycling, it is crucial to ensure that you possess the required permits. Seeking guidance from a reliable company is a great way to start, and requesting a demonstration using a sample will confirm the effectiveness of the shredder.

To gain insight into the company's history and how other businesses have used shredders to solve operational challenges,

it is advisable to visit the manufacturer's website and review case studies. Lastly, determining your budget is a crucial aspect of the decision-making process. It is important to note that some units, while initially less expensive, may be of inferior quality and end up costing more in the long run for operation and maintenance.

it is advisable to visit the manufacturer's website and review case studies. Lastly, determining your budget is a crucial aspect of the decision-making process. It is important to note that some units, while initially less expensive, may be of inferior quality and end up costing more in the long run for operation and maintenance.

Application

FAQ

Contact Candice to get our most up to date list.

Contact Candice on E:manager822650@njhanxin.com

M:+8613696733357

Contact Candice on E:manager822650@njhanxin.com

M:+8613696733357

Q: Why Choose Us?

1). Several Year's Experience

We have rich experience in equipment manufacturing. Our machines have high reputation both at home and abroad (Such as the Middle East, Southeast Asia, Africa and so on more than 10 countries and regions.)

2). Manufacturer, Not Dealer

Factory direct sale makes price more competitive.Customers are always welcome to visit our factory for machine test.

3). Fast Delivery

We promise the goods can be shipped out on delivery date after confirmation of the order.

Q: How do I know the quality of your machine?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.

Q: When we only purchase one shredder machine production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q: Which brand of motor will you use?

A: We use domestic motor manufatured by Chinese-famous suppliers, but you can choose Siemens or other brand motor. Don't worry about our machine's quality.

Q: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer's requirement, we will dispatch engineers to guide installation and traning about the operation of the machine.

1). Several Year's Experience

We have rich experience in equipment manufacturing. Our machines have high reputation both at home and abroad (Such as the Middle East, Southeast Asia, Africa and so on more than 10 countries and regions.)

2). Manufacturer, Not Dealer

Factory direct sale makes price more competitive.Customers are always welcome to visit our factory for machine test.

3). Fast Delivery

We promise the goods can be shipped out on delivery date after confirmation of the order.

Q: How do I know the quality of your machine?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.

Q: When we only purchase one shredder machine production line, can we use it to shred other scrap materials like?

A: Yes, you can.It depends on the difference of blades teeth and quantity, which can be customized.

Q: Which brand of motor will you use?

A: We use domestic motor manufatured by Chinese-famous suppliers, but you can choose Siemens or other brand motor. Don't worry about our machine's quality.

Q: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer's requirement, we will dispatch engineers to guide installation and traning about the operation of the machine.

Hot Searches