- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

20-100bag/min

-

Weight (KG):

-

350

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SOONTRUE

-

Model:

-

ZL-180PX

-

Packing speed:

-

20-100bags/min.

-

Packing film width:

-

120-320mm

-

General power:

-

4.0kw

-

Machine weight:

-

350Kg

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing

-

Packaging Type:

-

Bags, Pouch

-

Packaging Material:

-

Plastic

-

Production Capacity:

-

20-100bag/min

-

Weight (KG):

-

350

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SOONTRUE

-

Model:

-

ZL-180PX

-

Packing speed:

-

20-100bags/min.

-

Packing film width:

-

120-320mm

-

General power:

-

4.0kw

-

Machine weight:

-

350Kg

-

Marketing Type:

-

Ordinary Product

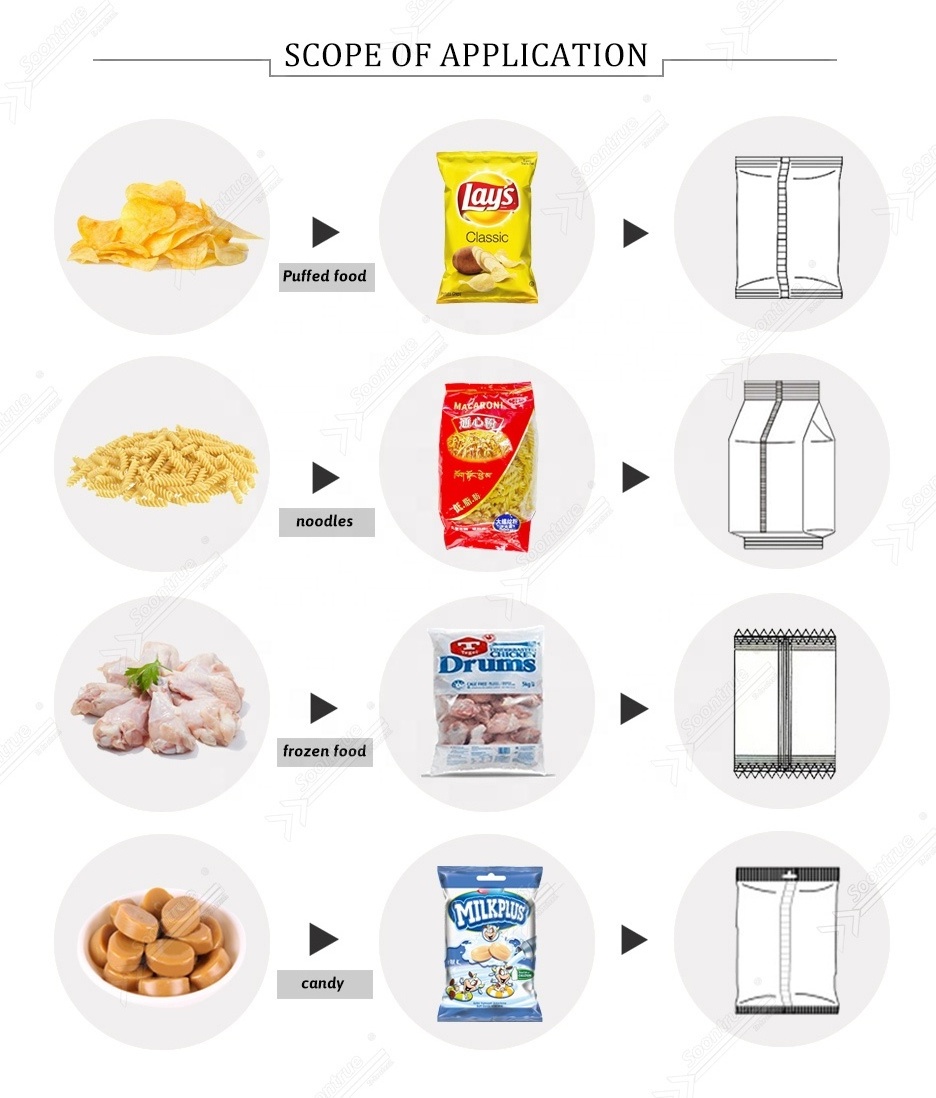

Application:

Mainly used for packing granules, strips, slice, liquid,lumps, powder with different

packing types.

1. Entire machine design is more optimized for more convenient operation.

2. Compact machine structure for more stable working.

3. SS304 machine frame with sand blasted treatment realizes nice appearance.

4. Key components are specially designed, fast packing speed.

5. Servo controlling system: Intelligent adjustment with higher accuracy is more

flexible for packing different products.

6. Bag types: 3 sides seal bag, pillow bag (w/o hanging hole, and chain pack

option)

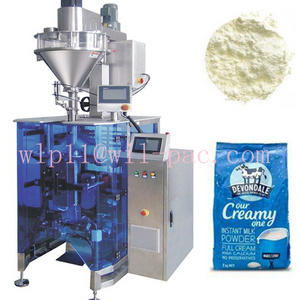

7. Filling systems: multi-head weigher, auger scale, volumetric cup filler, liquid

pump and

so on.

Servo film-pulling and film-loading assembly, with dancing arm moves up and down, realizing dynamic control of the film tension. Film travels above eye mark sensor, realizing precise film tracking and positioning.

Bag former

Drawn down by servo drive friction

pull-down belt, packing film enters to

bag former, realizing nice and neat

packaging performance. With user-

friendly design, it is easy to change

the

bag former ffor different film width.

Mid sealing assembly

Cylinder control mid sealing assembly,

with independent temperature control,

realizing precise and nice sealing appearance.

Servo control end sealing jaws move

in open-close motion, with independent

temperature control. Heated sealing

jaws will make top seal of one bag and

bottom seal of next bag at the same

time. Then Finished pillow bag will be

discharged.

Intuitive HMI display

Different settings for set up,

commissioning, daily operation and maintenance can be conducted via the touch screen. With memory function, easy for different packing size change over.

Different types of filling apparatus are optional to work with the packaging machine, such

as multi-head weigher, auger scale, volumetric cup filler, liquid pump etc. Also,

configuration with different kinds of lifter, working platform and discharge conveyor is

preference choice for most of businesses.

Machine frame made of 3mm & 5mm thickness stainless steel, realizing strong protection and steady operation.

SS304 machine body with non-finger surface treatment, nice appearance.

Machine with servo driven film pulling and film loading design, achieving accurate, fast and stable film feeding.

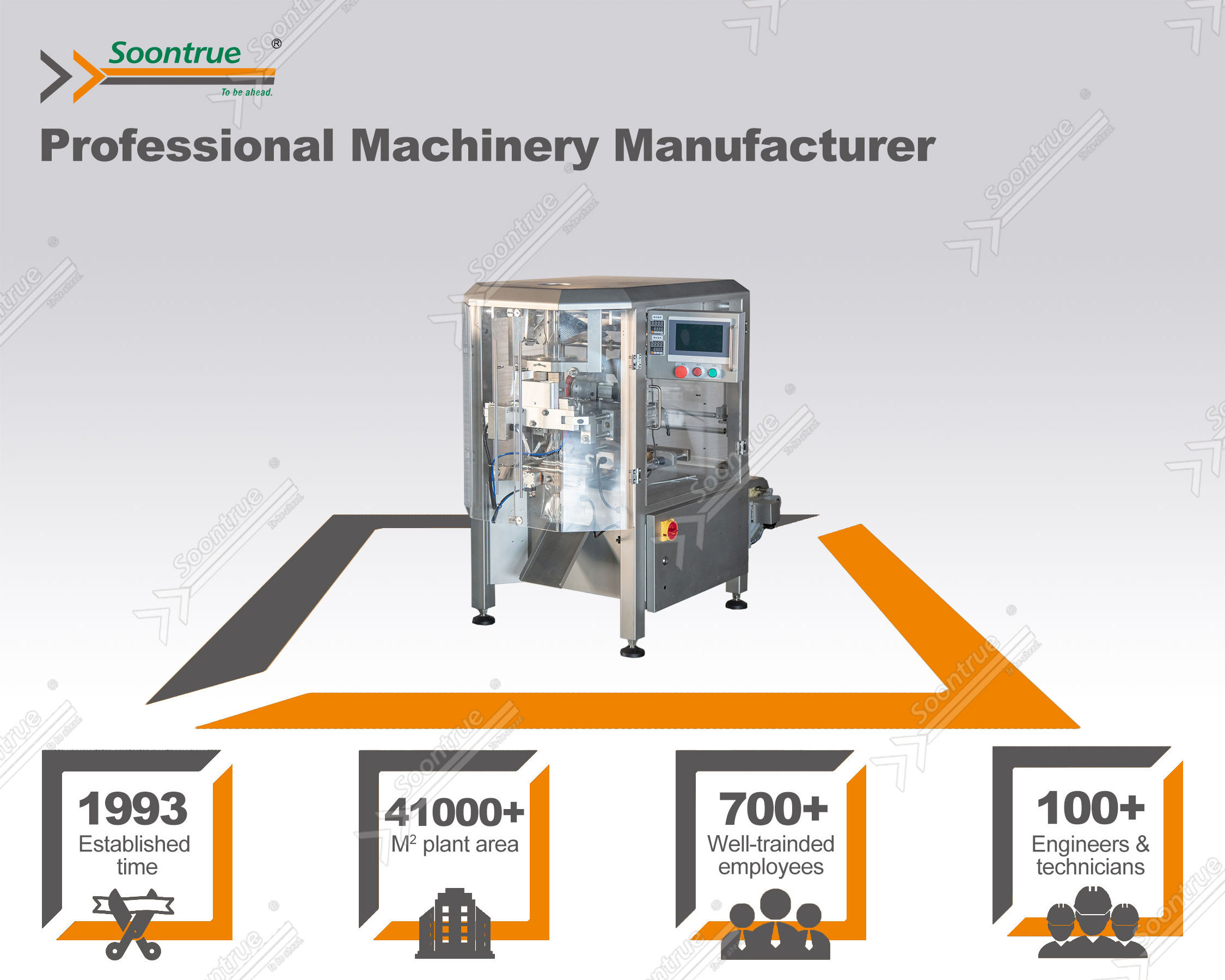

Foshan Soontrue Machinery Equipment Co., Ltd, established in 1993, is a leading

manufacturer engaged in the research & development, production, sales and service of

Horizontal packing machine, vertical packing machine and fully automatic packing system,

which are mainly applicable in bakery industry. Soontrue supplies more than 3000 packing

solutions to customers all over the world every year.

Foshan Soontrue has grown into a company with more than 400 staffs and 41,000 square

meters

along with well improved factory management.

|

Q1:

How should I choose the right VFFS packing machine?

|

|

|

|

|

||||

|

We will recommend suitable models and configurations based on your product characteristics, size, and package type. Normally, volumetric cup filler or multi-head weigher are optional for granular, block, and flake materials; linear weigher or auger scale for powder; liquid pump for different kind of liquid. For different packaging bag types, such as pillow bags, three-side seal bags, four-side seal bags, pre-made bags, etc., we also have different models to meet your needs.

|

|

|

|

|

||||

|

Q2: I'm worried that I don't know how to operate your machine

|

|

|

|

|

||||

|

Do not worry. Our pouch packing machine is servo controlled, which greatly simplifies the difficulty of operation and

commissioning. Most of the daily operation of the machine can be conducted by a few start-stop buttons and HMI. If you have different products or packages that need to be changed, we can provide instructional videos to give you step-by-step tutorial. Also, the HMI has memory function, which is convenient for you to reload the settings in the future. |

|

|

|

|

||||

|

Q3: If I buy your automatic packing machine, what technical support can I get?

|

|

|

|

|

||||

|

We have professional technical engineers to give you on line support. We can provide you with instructional videos for the installation and daily commissioning and maintenance. Online video call tutorial is also available for special cases.

For some custom-made solutions, our experienced after-sales technicians can also provide on-site installation and commissioning services on buyers cost (except special period, such as COVID-19). |

|

|

|

|

||||

|

Q4: How do we build trust in the first business?

|

|

|

|

|

||||

|

We believe that a win-win business must be based on our professional services and excellent products. Our team will fully study your needs, and clearly explain our products and solutions to you so that you can understand our services. We can take you to visit our modern factory through a video call, so that you can understand how your machine will be produced and let you know more about our products. Before delivery, we can cooperate with your partners to carry out factory acceptance test, or carry out acceptance through test video or video call. Make sure that the high quality packing machine you need is ready before shipment.

|

|

|

|

|

||||

|

Q5: How can I find the custom packing machine I need?

|

|

|

|

|

||||

|

We will fully communicate of the information of your products, packaging scheme, and feeding method. We have nearly 30 years of experience as a packing machine factory and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of products and packing films for testing, in order to find the most suitable and cost-effective solution for you.

|

|

|

|

|

||||

Hot Searches