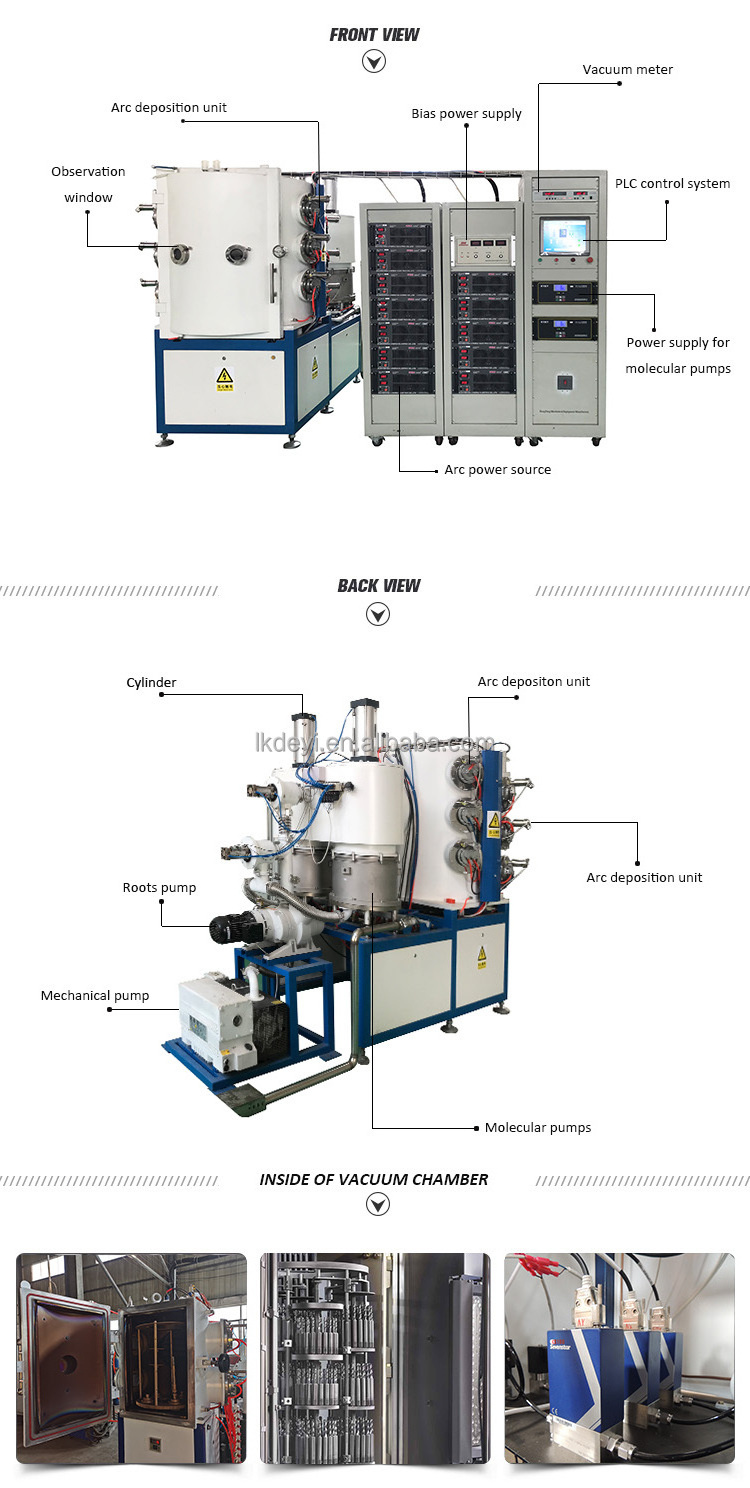

DYVAC use double layer of stainless steel 304 to manufacture the vacuum chamber , with advanced welding technology and ensure the

air tightness of the chamber . better vacuum pressure protection capability ,higher ultimate vacuum , More durable service life.

and built in high power heater and ensure the temperature inside the chamber .

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or customized

-

Power:

-

Custom Made

-

Dimension(L*W*H):

-

Custom Made

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers Service Machinery Overseas

-

Technology:

-

Multi Arc + Sputtering

-

Advantage:

-

High Efficiency Low Cost

-

Chamber Material:

-

Stainless Steel 304

-

paint colo:

-

Gold, Rose Gold, Blue, Gray, Black, Rainbow

-

controlling system:

-

PLC Touch Screen

-

business type:

-

manufacturer/supplier

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

pump system orign:

-

basis on your request

-

product:

-

Magnetron sputtering vacuum coating Machine

Quick Details

-

Machine Type:

-

Coating Equipment,PVD vacuum coating machine, Coating Equipment

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DYVAC

-

Voltage:

-

380V or customized

-

Power:

-

Custom Made

-

Dimension(L*W*H):

-

Custom Made

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers Service Machinery Overseas

-

Technology:

-

Multi Arc + Sputtering

-

Advantage:

-

High Efficiency Low Cost

-

Chamber Material:

-

Stainless Steel 304

-

paint colo:

-

Gold, Rose Gold, Blue, Gray, Black, Rainbow

-

controlling system:

-

PLC Touch Screen

-

business type:

-

manufacturer/supplier

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

pump system orign:

-

basis on your request

-

product:

-

Magnetron sputtering vacuum coating Machine

Product Description

Specification

|

DY Multi Arc Ion vacuum coating machine model and technical parameter

(hardware, ceramic, cutlery etc ) |

|

|

|

|

|

|

||||||

|

model

|

DY-700

|

DY -900

|

DY -1000

|

DY -1250

|

DY -1400

|

DY -1600

|

||||||

|

Chamber size

|

Ф700×H900mm

|

Ф900×H1100mm

|

Ф1000×H1200mm

|

Ф1250×H1350mm

|

Ф1400×H1600mm

|

Ф1600×H1800mm

|

||||||

|

Power type

|

Arc power, filament power, pulse bias power

|

|

|

|

|

|

||||||

|

Vacuum chamber structure

|

Vertical front door structure, postposition sucking gas system, double layer water cooling chamber

|

|

|

|

|

|

||||||

|

Vacuum chamber material

|

High quality stainless steel chamber

|

|

|

|

|

|

||||||

|

Ultimate vacuum

|

6.0×10-4Pa

|

|

|

|

|

|

||||||

|

Pumping time(no load)

|

pumping from atmosphere to 8.0×10-3Pa≤15per minutes

|

|

|

|

|

|

||||||

|

Vacuum pumping system |

Diffusion or molecular pump+ Roots pump+ mechanical pump+ holding pump

(The detailed model need to collocate according to customer need) |

|

|

|

|

|

||||||

|

arc power

|

4 sets or 6 sets

|

6 sets or 8 sets

|

8 sets or 10 sets

|

10 sets or 12 sets

|

14 sets or 16 sets

|

16 sets or 18 sets

|

||||||

|

Bias power

|

10KW/1set

|

20KW/1set

|

20KW/1set

|

30KW/1set

|

40KW/1set

|

50KW/1set

|

||||||

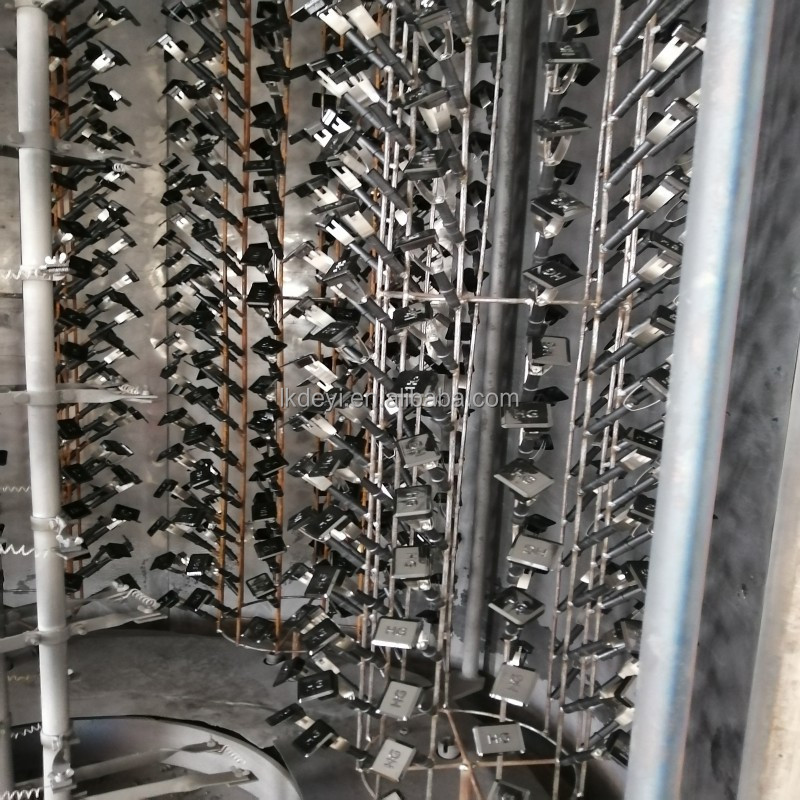

|

Workpiece rotating method

|

Planetary revolution and rotation, inverter control(controlled and adjustable)

|

|

|

|

|

|

||||||

Technological Process

Our Advantage

Double layer Vacuum Chamber

Excellent vacuum pumping system

DYVAC choose the famous Chinese brand pump for the vacuum pumping system . its Vacuum is fast and steady .to obtain high

efficiency coating cycle time , greatly reduces the vibration frequency and energy consumption of the equipment . We can offer the import brand pump service if the customer required .Such Leybold ,Osaka, Shimadzu ,Pfeiffer etc .

efficiency coating cycle time , greatly reduces the vibration frequency and energy consumption of the equipment . We can offer the import brand pump service if the customer required .Such Leybold ,Osaka, Shimadzu ,Pfeiffer etc .

Control System and Famous Electrical Production

Delta DVP series PLC programmable industrial controller, the whole machine automatic monitoring, protection, control, coating.

With manual, semi-automatic, fully automatic functions

With manual, semi-automatic, fully automatic functions

DYVAC’s 10th Arc Source and the Parts

Equipped with DYVAC’s 10th generation high-performance arc power supply and cathode arc source device , it means more uniform

coating film , leading reliable performance of continuous coating DYVAC keep the technology R&D , so the technology are

progressing .

coating film , leading reliable performance of continuous coating DYVAC keep the technology R&D , so the technology are

progressing .

Finished Product Photo

Packing & Delivery

FAQ

Q1. How about the quality control about your products? We have the ISO9001 QMS , CE certification. All machine will past the

internal quality test and field testing. Q2. Does your company provide after-sale service ? Yes. We have the field engineer to

set-up and debug the machine . After the machine is fully running . we have one year of quality warranty and full-life maintenance

service . Q3. Can you provide technical support about my work-flow? Yes . The Tongyi have more than 20 years of experience in

Vacuum coating territory. We also have an independent R&D department ,which will solve your production issue. Q4. Do you provide

the second-hand machine ? No. All machine in Tongyi are new . We don't manufacture the second-hand machine . Q5. Does your company

supply accessories for our spare parts after we bought your products ? Yes . We can supply you all the accessories especially for

some consumable material .

internal quality test and field testing. Q2. Does your company provide after-sale service ? Yes. We have the field engineer to

set-up and debug the machine . After the machine is fully running . we have one year of quality warranty and full-life maintenance

service . Q3. Can you provide technical support about my work-flow? Yes . The Tongyi have more than 20 years of experience in

Vacuum coating territory. We also have an independent R&D department ,which will solve your production issue. Q4. Do you provide

the second-hand machine ? No. All machine in Tongyi are new . We don't manufacture the second-hand machine . Q5. Does your company

supply accessories for our spare parts after we bought your products ? Yes . We can supply you all the accessories especially for

some consumable material .

Hot Searches