- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380/450v customized

-

Power:

-

6.5/37kw, Gas&Electric

-

Weight:

-

1800 KG

-

Dimension(L*W*H):

-

3200*3000*3000mm

-

Application:

-

Dual Duct Modular Dryer

-

Capacity:

-

100kg/h-500kg/h

-

Material:

-

Stainless Steel

-

Main Motor:

-

Siemens

-

Invertors:

-

Korea LG Brand

-

Bearing:

-

Japan NSK

-

Electric Device:

-

ABB

-

Product:

-

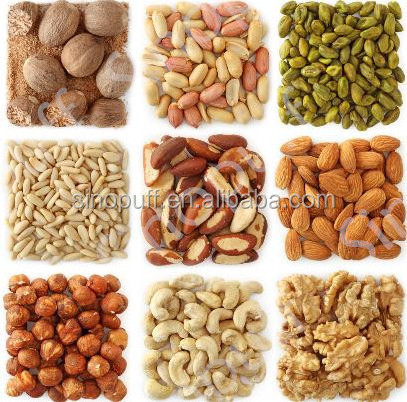

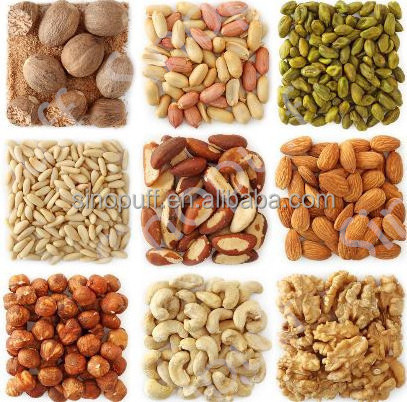

Snack Food,Peanut,sunflower seeds

-

belt:

-

Stainless Steel

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LXZ

-

Voltage:

-

220/380/450v customized

-

Power:

-

6.5/37kw, Gas&Electric

-

Weight:

-

1800 KG

-

Dimension(L*W*H):

-

3200*3000*3000mm

-

Application:

-

Dual Duct Modular Dryer

-

Capacity:

-

100kg/h-500kg/h

-

Material:

-

Stainless Steel

-

Main Motor:

-

Siemens

-

Invertors:

-

Korea LG Brand

-

Bearing:

-

Japan NSK

-

Electric Device:

-

ABB

-

Product:

-

Snack Food,Peanut,sunflower seeds

-

belt:

-

Stainless Steel

"Sinopuff" Sinopuff Industrial Puff Snack&Peanut Dryer

Drying is a key stage in many industries and in particular in the food processing industry.Sinopuff offers drying technologies to meet specific product and quality requirements.experts design drying systems to meet customer requirements: product quality and features, scale, cost efficiency and environmental impact.

Widely Application

Single-pass conveyor dryers are employed in the processing of snacks, cereals, dehydro-frozen fruits, nuts and vegetables;

Gentle Drying Process

This dryer uses air to transfer heat and remove moisture as the product moves through multiple temperature zones on a conveyor bed. Gentle handling of the product is ensured, as there are no turnovers or drops during drying.

Efficient Thermal Processing

Use independent temperature zones to customize the thermal process and maximize the efficiency of heat/mass transfer. As the product moves through the separate processing zones, it is exposed to controlled airflow and temperature conditions. Precise control of airflow volume, temperature and humidity enables the development or preservation of product characteristics while keeping operating efficiency high and utility costs low. The dual plenum provides the ultimate in moisture uniformity with consistent airflow delivery to both sides of the product bed.

Customized Design

Customers can specify input and discharge and other operating line parameters to ensure the unit fits the plant design.

Easy Installation, Cleaning, & Operation

The dryer use standard modular structure, lower installation cost, and shorter start-up time. It also have superior access for cleaning and maintenance. Dryer floors and roofs are pitched for easy cleaning and continuously welded for maximum sanitation. Easy access via large doors and removable panels allows cleaning to be done quickly and thoroughly during routine operations.

Factory Strength

1. Years Experiences of sales, techician, engineers in snack extrusion machinery

2. Post-graduated techician design & R&D group will help you for any question/problems before & after purchasing.

3. Professional processing team & reliable spare parts supplier like Siemens, LG, Japan NSK to ensure the machine high standard quality.

Our Exhibition & Customer

We take active in kinds of exhibition, both chine domestic & overseas;

Sincerely cooperate with customer from all over the world.

Pre-Sales Service

* Professional technical project and sales consultation service support timely

* Sample testing support.

* View our Factory

During Production

* Timely updates the machine status for customer to ensure delivery time, and quality

* Machine testing video and photos will be provided for inspection, if the customer can't come;

Before

Shipment

*

Machine will be totally cleaned & doing rust prevention before package.

* Wooden Cases/Pallet will be provided to ensure the safety shipment.

Afte

r-Sales Service

* Providing professional and expert technical engineers to supply the training and installation service.

* Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, and spare parts;

Factory Address:

Yuanzhuang Industrial Park, Liuchangshan Road, Shizhong District, Jinan City, Shandong Province.

Tel: 86-531-82987888 Fax: 86-531-86013303

Q:

Are you a trader or manufacturer?

A: We are

the professional extrusion food machinery manufacturer in China, our factory is in Jinan City, Shandong Province.

Q:

How can I get the proper machine for our business?

A: Just let us know your interested product, capacity & production details. We will suggest the most suitable machine and professional solution.

Q:

This is my first time using this kind of machine, is it easy to operate?

A: Of course the machine is easy to operate. Sinopuff Group is not only manufacturer but also solution provider ,for our extruder ,once the machine arrived in your city, we will dispatch after-service engineer for overseas installation & training.

Q:

Will you provide the snack formula for production?

A: Yes, Our R&D snack department will provide the basic formula, and help the customers to analysis the detailed formula based on the sample product you want.

Q:

If the machine has problem in my place, how could I do?

A: Usually there won't be any problem under "normal use" as per the user manual. But in case you have any problem, our professional after-service team will provide you any support you need any time!