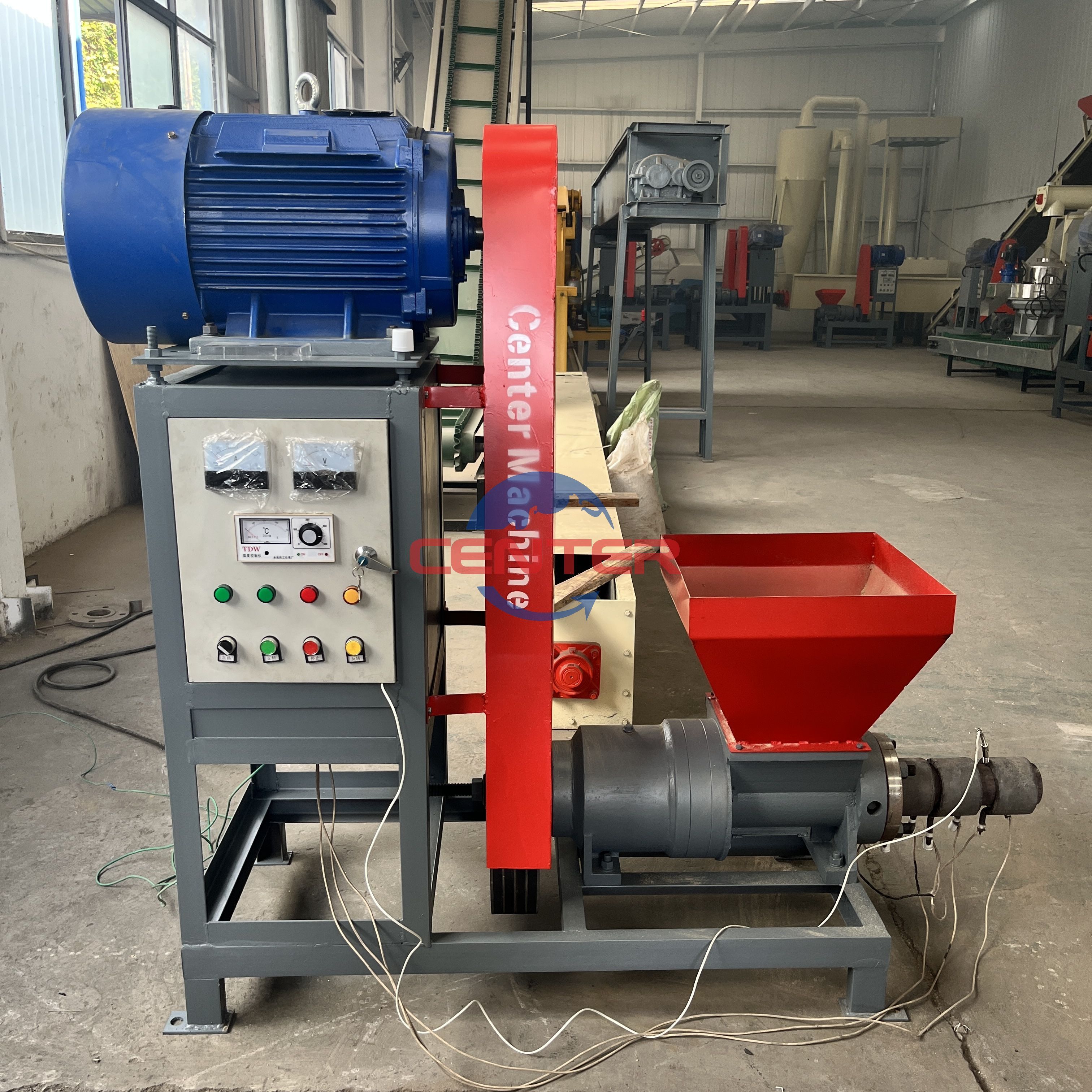

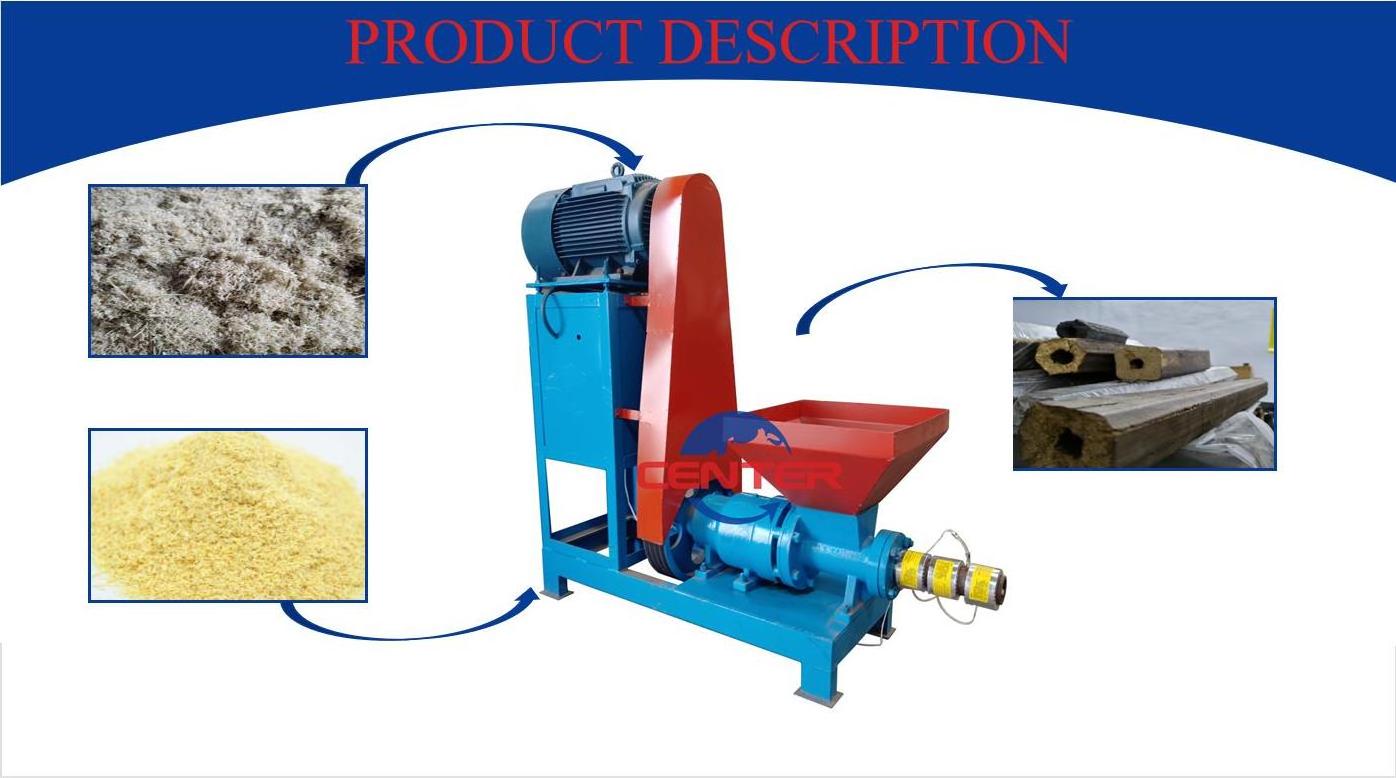

1.Extended rear propulsion propeller

The propeller is elaborately made by strong wear-resistant alloy, which the service life has been increased by 3-4 times.