- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

850x520x900MM

-

Weight (T):

-

0.28 T

-

Power (kW):

-

70

-

Working Theory:

-

Electromagnetic Induction Heating

-

Feature:

-

Fast, energy-saving, safe, high efficiency

-

Application:

-

gold copper aluminum steel iron melting

-

Model Number:

-

WXM

-

Outpot Oscillating:

-

1-20KHz

-

Input Voltage:

-

3 Phase 380V, 50/60HZ

-

Capacity:

-

1KG to 300KG

-

Corollary Equipment:

-

Water Cooling System

-

HS code:

-

8514200090

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

WANGXIN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

850x520x900MM

-

Weight (T):

-

0.28 T

-

Power (kW):

-

70

-

Working Theory:

-

Electromagnetic Induction Heating

-

Feature:

-

Fast, energy-saving, safe, high efficiency

-

Application:

-

gold copper aluminum steel iron melting

-

Model Number:

-

WXM

-

Outpot Oscillating:

-

1-20KHz

-

Input Voltage:

-

3 Phase 380V, 50/60HZ

-

Capacity:

-

1KG to 300KG

-

Corollary Equipment:

-

Water Cooling System

-

HS code:

-

8514200090

Iron Steel Scraps Aluminum Induction Melting Furnace For Melting

Main Features

Industrial Induction Melting Furnace

1. Wang Xin melting furnace can be used for the melting of steel, stainless steel, brass,cooper,gold and so on.

2. Because of the stirring effect which caused by the magnetic force, the melting pool can be stirred during the melting course to

ease the floating of the flux and oxides to produce high quantity casting parts.

3. Wide frequency range from 1KHZ to 20 KHZ, working frequency can be designed by changing the coil and compensating capacitor

according to the melting material, quantity, stirring effect desire, working noise, melting efficiency and other factors.

4. Compared with SCR medium frequency furnace, it can be energy at least 20% and up.

5. Small and light, a lot of modes can be selected to melt different amount of metals. Not only it is suitable for the factory,

but also suitable for the colleges and researching companies to used.

6. 24 hours non-stop melting ability.

7. It’s easy to change melting furnace to different capacity, different materials,different way of pouring out, to suitable for

all kinds of requirements.

Melting Ability

Machine Models and Maximum Melting Ability

Melting speed: the first cool furnace 50-60mins/furnace, the second heated furnace 20-30mins/furnace

|

Model

|

Steel ,iron

|

Copper, Gold , Silver

|

Aluminum

|

|

WXM-15KW Melting Furnace

|

|

10KG

|

3KG

|

|

WXM-25KW Melting Furnace

|

5KG

|

20KG

|

6KG

|

|

WXM-35KW Melting Furnace

|

10KG

|

30KG

|

10KG

|

|

WXM-45KW Melting Furnace

|

18KG

|

50KG

|

20KG

|

|

WXM-70KW Melting Furnace

|

25KG

|

100KG

|

30KG

|

|

WXM-90KW Melting Furnace

|

40KG

|

120KG

|

40KG

|

|

WXM-110KW Melting Furnace

|

50KG

|

150KG

|

50KG

|

|

WXM-160KW Melting Furnace

|

100KG

|

250KG

|

100KG

|

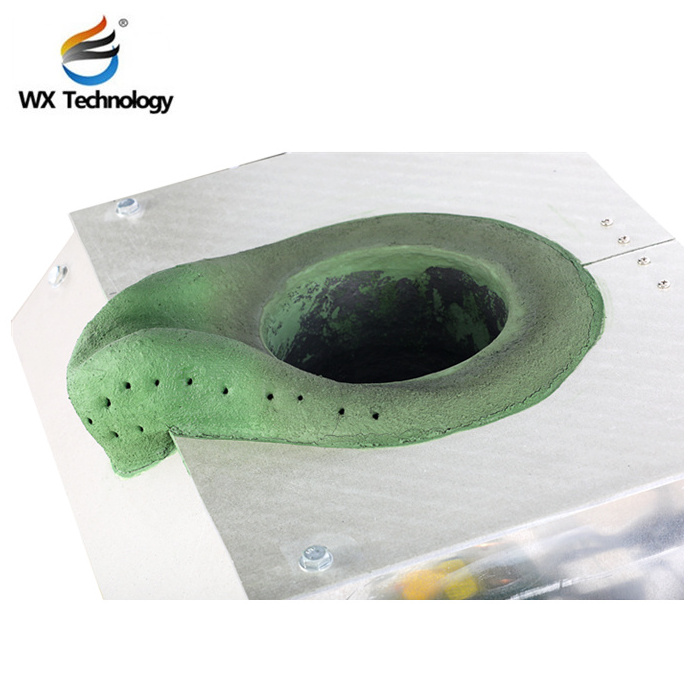

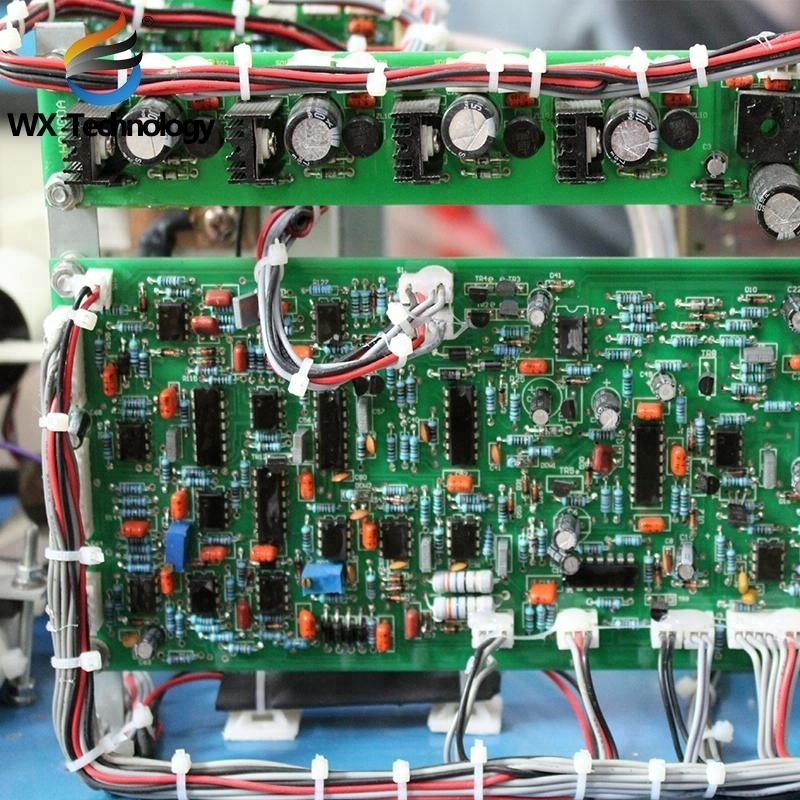

Main Components

Infineon IGBT Module

High Precision PCB Boards

Imported Filter Capacitor

Technical Parameters

|

Model

|

Input Voltage

|

Frequency

|

Max Input Power

|

Max Input Current

|

|

WXM-15

|

3 phase 380V, 50/60HZ

|

1-20KHZ

|

15KVA

|

24A

|

|

WXM-25

|

3 phase 380V, 50/60HZ

|

1-20KHZ

|

25KVA

|

36A

|

|

WXM-35

|

3 phase 380V, 50/60HZ

|

1-20KHZ

|

35KVA

|

51A

|

|

WXM-45

|

3 phase 380V, 50/60HZ

|

1-20KHZ

|

45KVA

|

70A

|

|

WXM-70

|

3 phase 380V, 50/60HZ

|

1-20KHZ

|

70KVA

|

105A

|

|

WXM-90

|

3 phase 380V, 50/60HZ

|

1-20KHZ

|

90KVA

|

135A

|

|

WXM-110

|

3 phase 380V, 50/60HZ

|

1-20KHZ

|

110KVA

|

175A

|

|

WXM-160

|

3 phase 380V, 50/60HZ

|

0.5-10KHZ

|

160KVA

|

240A

|

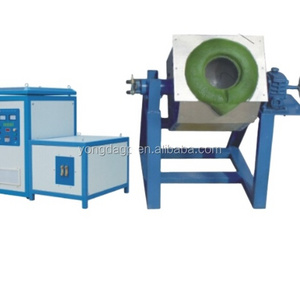

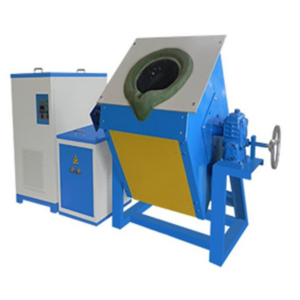

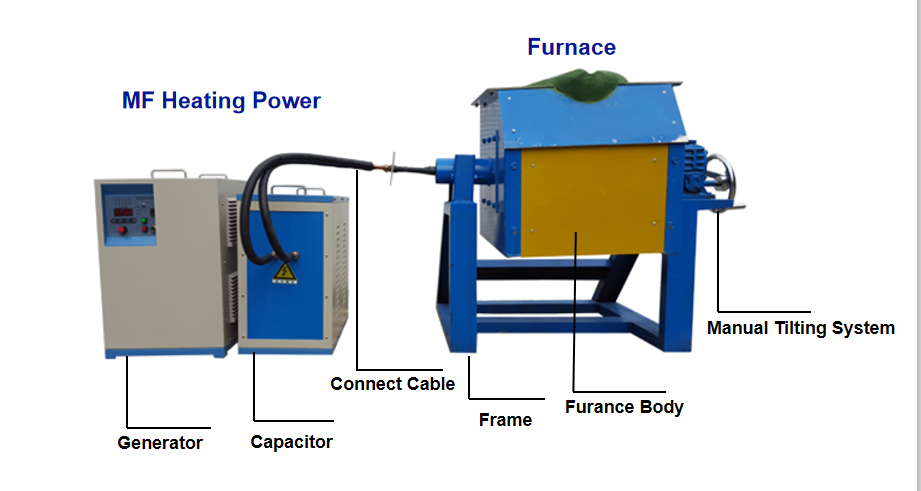

Machine Show

Induction Melting Furnace mainly include two parts: induction heating power and tilting furnace

Medium Frequency Induction Heating Power (Frequency 0.5-20KHZ)

WXM-15/25/35

WXM-45/70/90

WXM-110/160

Tilting Furnace

Real Working Scenarios

Recommend Products

Customer Photos

Evaluation From Customer

Qatar Customer

Croatia Customer

Bangladesh Customer

Amernia Customer

Finland Customer

Alibaba Customer

Hot Searches