Xiamen LFT composite plastic Co.,Ltd is an integrated system of r&d, production and sales. We provide a single supplier selection for product design, performance analysis, compound formulation, compound particle production and finished product processing.

- Product Details

- {{item.text}}

Quick Details

-

color:

-

Natural color or Customized

-

Shape:

-

Pellets/Granules

-

Material:

-

PPA-NA-LGF, Composite Polymer

-

Product name:

-

Price Polyphthalamide Resin Long Glass Fiber Filled Ppa Plastic

-

Color:

-

Natural

-

Certificate:

-

ISO

-

Appearance:

-

Granular

-

Type:

-

Modified

-

Keyword:

-

Long Glass Fiber Filled Ppa Plastic

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LFT-G

-

Model Number:

-

PPA-NA-LGF

-

color:

-

Natural color or Customized

-

Shape:

-

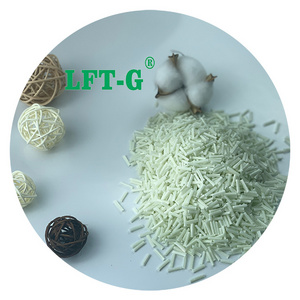

Pellets/Granules

-

Material:

-

PPA-NA-LGF, Composite Polymer

-

Product name:

-

Price Polyphthalamide Resin Long Glass Fiber Filled Ppa Plastic

-

Color:

-

Natural

-

Certificate:

-

ISO

-

Appearance:

-

Granular

-

Type:

-

Modified

-

Keyword:

-

Long Glass Fiber Filled Ppa Plastic

Polyphthalamide Resin Long Glass Fiber Filled Plastic

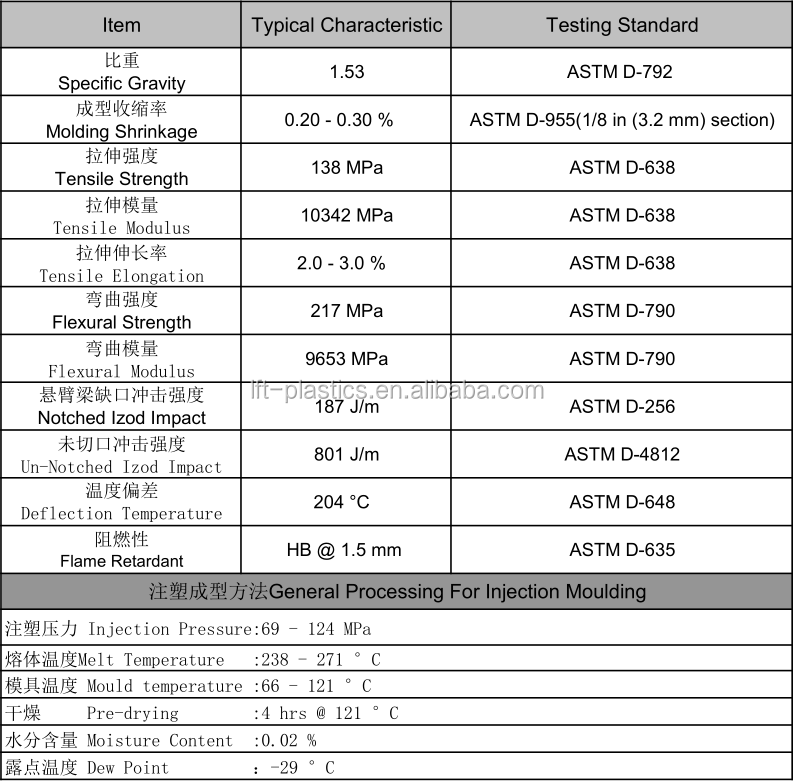

Polyphthalamide is a high-performance resin and member of the nylon family with exceptional thermal, mechanical, and physical properties. It is hygroscopic, opaque, semicrystalline, and can be used in plastic injection molding. Most PPA are filled with glass fiber or carbon fiber to enhance stiffness for high-temperature applications. As a result, PPA is often used in applications in place of metal or higher-priced thermoplastic.

|

SAMPLE AVAILABLE

|

|

|

|

|||

|

Product Name

|

|

Polyphthalamide Resin Long Glass Fiber Filled Plastic

|

|

|||

|

Color

|

|

Natural Color or Customized

|

|

|||

|

Product Number

|

|

PPA-NA-LGF

|

|

|||

|

Advantage

|

|

Very high stiffness and strength

|

|

|||

|

|

|

Good heat, chemical, and fatigue resistance

|

|

|||

|

|

|

Good dimensional stability

|

|

|||

|

MOQ

|

|

25kg/bag

|

|

|||

|

Shipment Port

|

|

Xiamen

|

|

|||

|

Delivery Time

|

|

3-45 days after shipment

|

|

|||

|

Packaging Details

|

|

25KG/Bag(also as the customers required)

|

|

|||

|

After Sales Service

|

|

24 hours online

|

|

|||

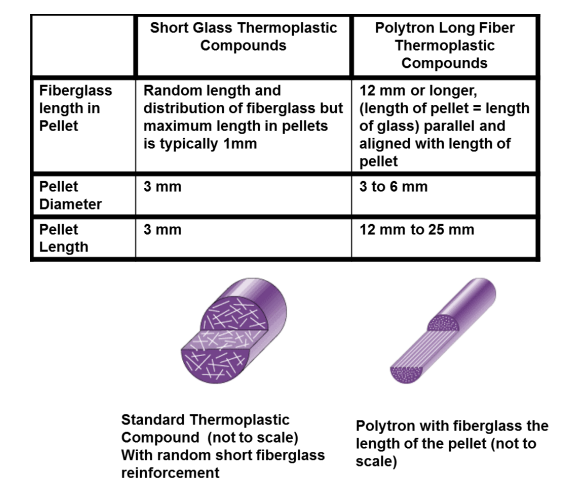

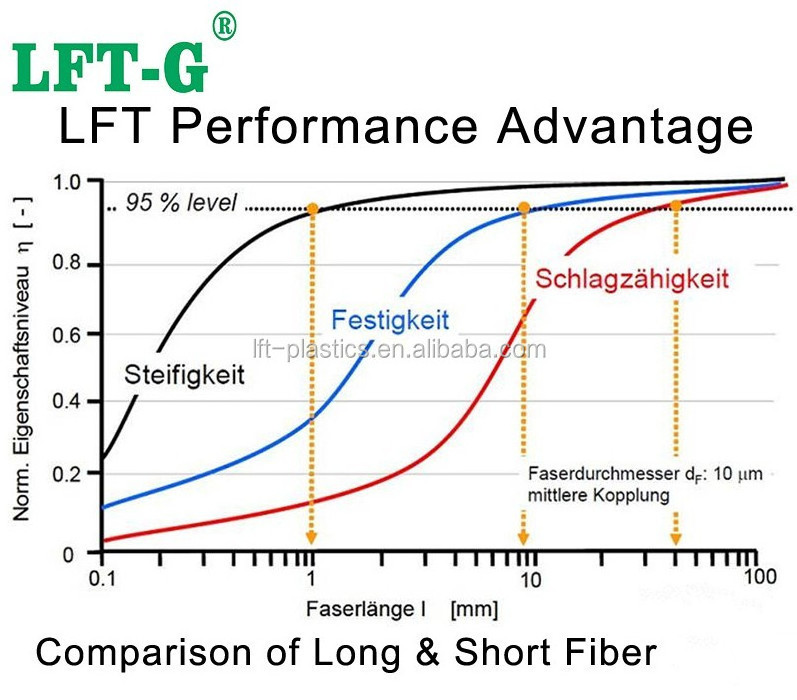

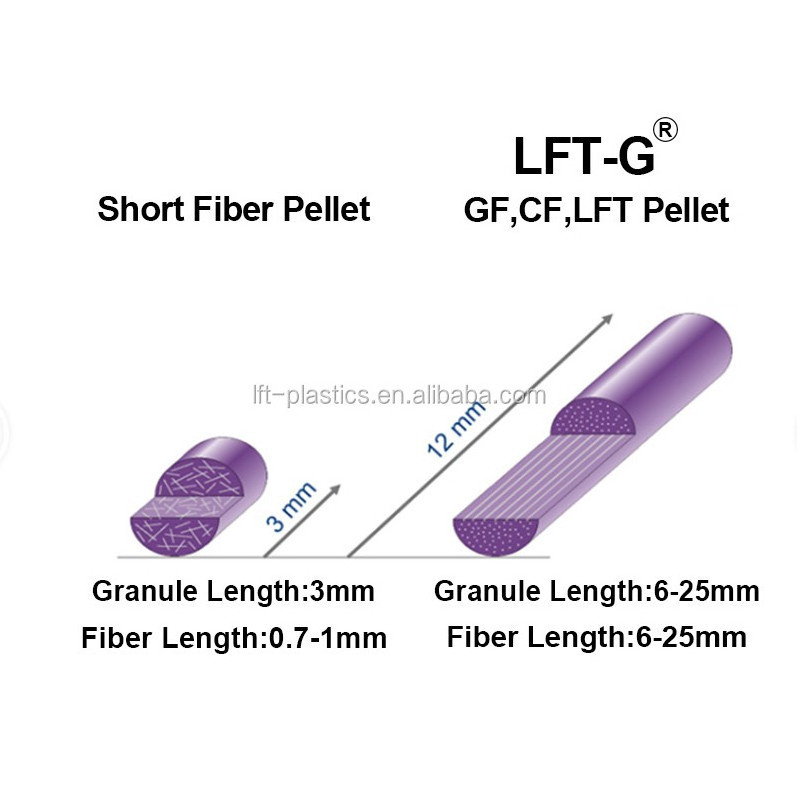

Comparison of Long & Short Fiber Pellets

LFT is a long-fiber reinforced thermoplastic new material that is made by fusion molding of fibers and matrix resin using a pultrusion process; this long-fiber material has better mechanical and mechanical properties than short-fiber materials, This is mainly due to the good filling properties of the long fibers, the short long fibers at the ends of the fibers, the long fibers mixed in the mold, intertwined, turned over and bent, unlike the short fibers arranged along the water flow direction. As a result, long fiber blends are highly homogeneous and straightforward and can be used in a wide range of markets as a lightweight metal substitute or as a substitute for other materials.

Note :

The above data is for reference only. If you have any needs or questions, please contact me, and we provide

free samples

for your sample.

Polyphthalamide has many uses. It is used for electronics and electrical, automotive, cables & wires, and many other applications.

Polyphthalamide is used chiefly as an alternative for several metal components in the industries such as automotive and others.

PPA can be used for fuel & coolant lines, motor bobbin parts, pump wear rings, fuel line connectors, fuel cut-off valves, water heater manifolds, fuel modules, thermostat housings, coolant pumps, air coolers, and LED headlights.PPA enables the creation of automobile components with better mechanical strength and decreased overall vehicle weight.

As a result, the use of PPA helps to lower fuel consumption.

PPA is also used for multiple electronic applications, as the high melting point of PPA allows SMD parts

molded from PPA to be assembled using a lead-free soldering process. PPAs are also utilized for USB-C connectors, cable & wire protection, and LED mounts.

Other uses for PPA-based resins include gas pipes and supply lines for the oil industry.

2. Add resin, additives, etc., form a unique formula. Improve flowability, hardness, temperature stability.

3. The pre-treated carbon fiber is placed on the machine, and the resin is evenly covered on its surface.

4. Use the machine to solidify the material, and the fiber and resin are both sufficiently bonded.

5. According to the requirements of the product, cutting particles.

Sample

: free

,but freight charged on customers

Delivery Time

: 7-45days

Delivery Method:

by sea , by air

Why Choose US

1.Possess own factories , can provide 100% factory price.

2.Our team has 20 years of comprehensive knowledge.

3.Advanced production equipment.

4.Good quality and good service.