- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

zzhhgy

-

Year:

-

2024

-

Power (kW):

-

400

-

Weight (KG):

-

55000

-

Marketing Type:

-

New Product 2023

-

Color:

-

Blue

-

Application:

-

Pipe/tube bending

-

Heating method:

-

Induction heating

-

Cooling method:

-

Circulating water cooling

-

Material:

-

Stainless steel, carbon steel, alloy steel

-

Working voltage:

-

380V, 3N, 50/60Hz

-

Control system:

-

PLC(imported Brand)

-

Control axle:

-

Single

-

Bending speed:

-

1-100mm/min

-

Weight:

-

55T

Quick Details

-

Bending Radius (mm):

-

159 - 720

-

Max. Bending Angle (Deg):

-

180

-

Bending Precision (Deg):

-

0.5

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

zzhhgy

-

Year:

-

2024

-

Power (kW):

-

400

-

Weight (KG):

-

55000

-

Marketing Type:

-

New Product 2023

-

Color:

-

Blue

-

Application:

-

Pipe/tube bending

-

Heating method:

-

Induction heating

-

Cooling method:

-

Circulating water cooling

-

Material:

-

Stainless steel, carbon steel, alloy steel

-

Working voltage:

-

380V, 3N, 50/60Hz

-

Control system:

-

PLC(imported Brand)

-

Control axle:

-

Single

-

Bending speed:

-

1-100mm/min

-

Weight:

-

55T

|

Product name

|

pipe bender

|

Voltage

|

380V 50Hz 3N

|

|

Model Number

|

WGYC-720

|

Application

|

pipe bending

|

|

Color

|

blue or customized

|

Certification

|

ISO

|

|

Power

|

600kw

|

Warranty

|

1 year

|

|

Bending diameter

|

219-720mm

|

Cooling method

|

water

|

|

Bending radius

|

2.0-6.0D

|

MOQ

|

1 set

|

|

Bending angle

|

0-180°

|

Price

|

negotiation

|

|

Wall thickness

|

8-80mm

|

Loading Port

|

Shanghai

|

Specifications

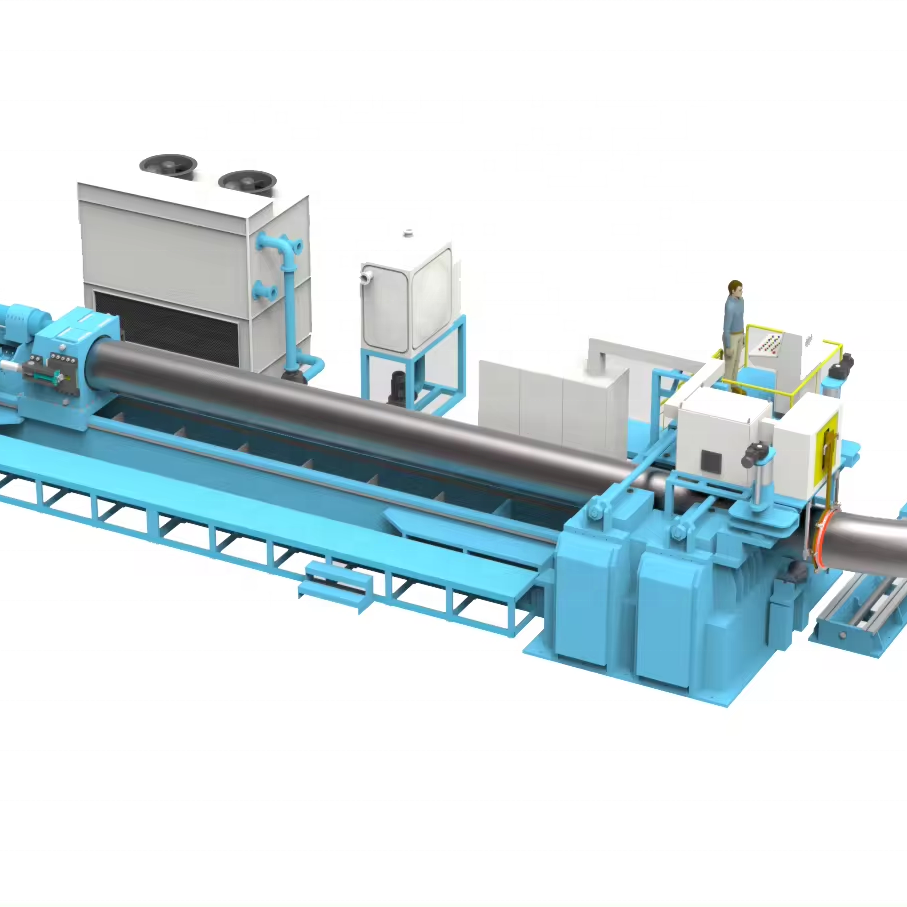

1. The induction hot pipe bender is mainly made of four parts:(1) induction heating system (2) pipe pusher (3) control power supply (4) CNC unit

2. The complete set of cnc induction hot pipe bender takes well advantages of electron magnetic thoery which can convert the 3 phase power frequency into single phase medium frequency power supply. This technology applies a bending force to a material that has been locally heated up by an eddy current induced by a fluctuating electromagnetic field.

3. To ensure uniform without risk of overheating, the temperature is computer controlled and regulated via an infrared camera.

Features & Advantages:

|

Model

|

Pipe diameter

(mm)

|

Max. Thrust (T)

|

Bending radius

|

Bending Angle (°)

|

Induction Heating Power(KW)

|

|

WGYC-219

|

76-219

|

60

|

≥1.5D

|

0-180

|

160

|

|

WGYC-325

|

76-325

|

70

|

≥2.5D

|

0-180

|

200

|

|

WGYC-426

|

108-426

|

100

|

≥3D

|

0-180

|

250

|

|

WGYC-530

|

159-529

|

120

|

≥3D

|

0-180

|

300

|

|

WGYC-630

|

159-630

|

160

|

≥3D

|

0-180

|

400

|

|

WGYC-720

|

219-720

|

180

|

≥3D

|

0-180

|

500

|

|

WGYC-830

|

219-830

|

220

|

≥3D

|

0-180

|

550

|

|

WGYC-1020

|

426-1020

|

260

|

≥3D

|

0-180

|

600

|

|

WGYC-1220

|

529-1220

|

300

|

≥3D

|

0-180

|

700

|

|

WGYC-1420

|

630-1420

|

350

|

≥3D

|

0-180

|

800

|

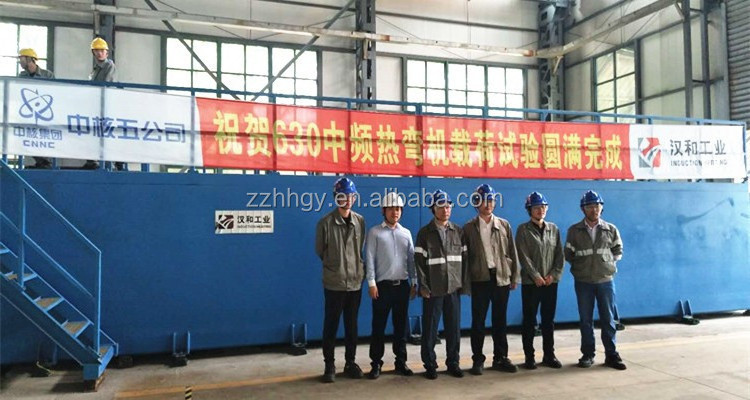

Zhuzhou Hanhe Industrial Equipment Co., Ltd is located in Zhuzhou which is an emerging industrial city. Zhuzhou Hanhe is engaged in the design, manufacturing and sales of induction heating power supply, CNC induction quenching & tempering machine, vacuum metallurgy, ultra high temperature sintering and graphitation, pipeline equipment, 3D metal printing additional manufacturing.

Zhuzhou Hanhe has an abundant technical force and strong research &development ability. It is equipped with a design team made up of experts and establishes close cooperation relations with many scientific research institution and enterprises home and abroad. The main designers have rich experience in design, research and production. They have been engaged in induction heating equipment and vacuum electric furnace for more than 20 years.

The products are widely applied in melting, diathermanous, quenching, high temperature sintering, ultra high temperature graphitization, heating fit loading&unloading, semi-conductivity refinement etc. They are suitable for precise cast, iron and steel, steel pipes, automobile & motorcycle spare parts, railway, aerospace, mechanical manufacturing, nuclear power, 3D printing, non-ferrous metal, cemented carbide and solar energy battery etc.

Our most professional packaging

Transport of large trucks to the seaport

And international transport cooperation

1. Customized products are welcome.

2. Pre-sales service:introduction of products, technical consulting and e-catalogue for your reference, knowing customers real needs, making proper proposal.

3. On-purchase service: real-time and in-time procedure following up and feedback.

4. After-sales service: instruction on installation, debugging of the equipment, trainning for the operator, 1 year guarantee, lifetime technical support, 24h response when customer calls.

|

Terms of payment

|

30%T/T as deposit, and 70% T/T before delivery.

|

|

Terms of delivery

|

EXW, FOB, CIF

|

|

Time of delivery

|

90-150 working days after the receipt of down payment

|

|

Manufacturer/trading company

|

We are anintergrated industrial and trading company.

|

|

Pre-sale service

|

We can provide technical consulting and proper proposal.

|

|

After-sale service

|

1 year guarantee time, and life-long technical support.

|