Yogurt production line is to turn the milk or milk powder into yogurt. It is composed of several tanks, including a storage tank,

refrigeration tank, preheating tank, homogenizer, pasteurizer tank, and fermentation tank. Finally, the finished yogurt is packed

into the cup by a yogurt filling machine. The capacity of this yogurt processing line ranges from 100L-10,000L, and we can customize

it for you according to your need. With reasonable prices and automatic operations, the Ace yogurt production line is widely

applied to dairy processing industries, beverage plants, and yogurt shops, etc.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 380V 440V 480V

-

Power:

-

0.75-2.2KW

-

Weight:

-

500 KG

-

Material:

-

Stainless Steel 304/316L

-

Capacity:

-

100-10000L

-

Function:

-

Milk Production Line

-

Application:

-

raw milk /Beverage,juice.dairy, milk

-

Usage:

-

Dairy Product Production Line

-

Milk tank type:

-

horizontal and vertical

-

Surface treatment:

-

mirror finish or matt finish

-

Motor Power:

-

0.75kw--7.5kw

-

Agitator Speed:

-

36rpm/min

-

Machines type:

-

yogurt making machines

Quick Details

-

Marketing Type:

-

New product 2024

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Voltage:

-

220V 380V 440V 480V

-

Power:

-

0.75-2.2KW

-

Weight:

-

500 KG

-

Material:

-

Stainless Steel 304/316L

-

Capacity:

-

100-10000L

-

Function:

-

Milk Production Line

-

Application:

-

raw milk /Beverage,juice.dairy, milk

-

Usage:

-

Dairy Product Production Line

-

Milk tank type:

-

horizontal and vertical

-

Surface treatment:

-

mirror finish or matt finish

-

Motor Power:

-

0.75kw--7.5kw

-

Agitator Speed:

-

36rpm/min

-

Machines type:

-

yogurt making machines

Ace Verre De Pot Yogurt Dosage For Sale

Custom Made 100L- 10,000L Yogurt and milk Production equipment, 22 Years Of Experience. Reasonable Price And Best Service, CE Certificated Products.15-30 day fast delivery. Please contact us for the offer.

Video

Products Description

Description

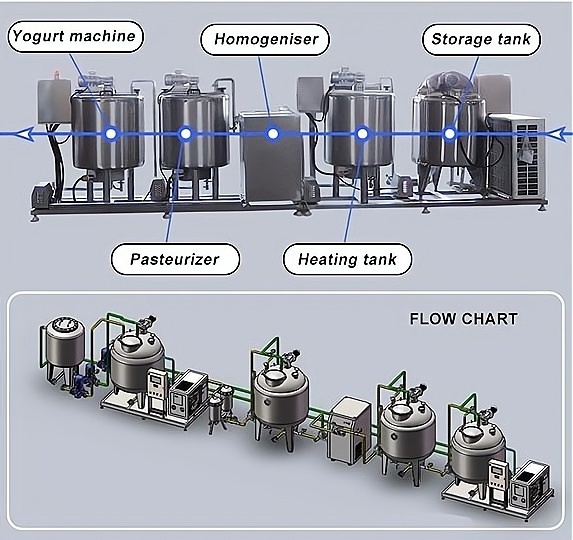

Milk processing line include:

1. Storage tanks 2. Duplex filter 3. Preheating milk 4. Homogenizer 5. Milk pasteurizer 6. Cooling 7. Filling and capping machine 8. Cleaning in place

Yogurt milk processing line include:

1. Storage tanks 2. Duplex filter 3. Preheating milk 4. Homogenizer 5. Milk pasteurizer 6. Cooling 7. Yogurt fermentation tank 8. Filling and capping machine 9. Cleaning in place

1. Storage tanks 2. Duplex filter 3. Preheating milk 4. Homogenizer 5. Milk pasteurizer 6. Cooling 7. Filling and capping machine 8. Cleaning in place

Yogurt milk processing line include:

1. Storage tanks 2. Duplex filter 3. Preheating milk 4. Homogenizer 5. Milk pasteurizer 6. Cooling 7. Yogurt fermentation tank 8. Filling and capping machine 9. Cleaning in place

Preheating Tank

1. The tank wall adopts advanced honeycomb rice plate evaporator to directly exchange heat and cool with milk.

2. The refrigeration compressor is imported from the United States Taking or France's Maypole fully enclosed compressor unit and the imported expansion valve and solenoid valve are equipped with a reliable midpoint protector, which will not burn the compressor due to overload or system failure.

3. The tank body is all made of SUS304 or 316 stainless steel, with pressurized automatic

rotating cleaning CIP spray head and automatic stirring device.

4. The insulation layer is made of polyurethane foam with good thermal insulation performance.

Duplex Filter

The double filter is also called the double switch filter. It is made up of two stainless steel filters in parallel. It has the

advantages of novel and reasonable structure, good sealing, strong flow capacity, and easy operation. It has a wide range of

applications and strong adaptability. The multi-purpose filtering equipment. In particular, the probability of side leakage of the

filter bag is small, the filter accuracy can be accurately guaranteed, and the filter bag can be replaced quickly, and the filter

basically has no material consumption, which reduces the operating cost.

Homogenizer

The homogenizer device adopts a stainless steel system, which can effectively separate the surface of the protective body sample

and the uniform sample of microorganisms contained therein. The sample is packed in a disposable sterile homogenization bag and

does not touch the instrument. It has a gentle homogenization and no sample. The characteristics of pollution, no damage, no

heating, no need for sterilization, no need to wash the utensils, meet the requirements of fast, accurate results and good

repeatability.

and the uniform sample of microorganisms contained therein. The sample is packed in a disposable sterile homogenization bag and

does not touch the instrument. It has a gentle homogenization and no sample. The characteristics of pollution, no damage, no

heating, no need for sterilization, no need to wash the utensils, meet the requirements of fast, accurate results and good

repeatability.

Sterilization Tank

The sterilization tank is currently one of the most ideal and effective milk sterilization equipment. It is made of high-quality

stainless steel and can control the water temperature to 85°~90° in the sterilization tank for all kinds of packaging or canned

food. It can have a sterilization effect, and it can ensure that the nutritional ingredients such as protein do not fluctuate

within a large temperature difference range, maintain the original quality, taste, and color of the food, and achieve no

preservatives on the food, which is beneficial to the health of consumers. In particular, the shelf life and storage period can be

extended.

stainless steel and can control the water temperature to 85°~90° in the sterilization tank for all kinds of packaging or canned

food. It can have a sterilization effect, and it can ensure that the nutritional ingredients such as protein do not fluctuate

within a large temperature difference range, maintain the original quality, taste, and color of the food, and achieve no

preservatives on the food, which is beneficial to the health of consumers. In particular, the shelf life and storage period can be

extended.

Cooling Tank

1. Cool down the sterilized milk to prepare for the next inoculation.

2. The machine has three layers, the outermost insulation

layer, electric heating;

3. The body is all made of 304 stainless steel processing;

4. It can be pre-cooled, fermented and

sterilized.

Fermenter

1. Self-control, in temperature and time.

2. The machine has three layers, the outermost insulation layer, electric heating;

3. The body is all made of 304 stainless steel processing;

4. It can be pre-cooled, fermented and sterilized.

How to clean yogurt production line?

We have a special CIP cleaning system that consists of three stainless steel tanks with pumps, and water, acid, and alkali are stored in these tanks respectively. The cleaning step is water-alkali -water-acid-water, and it can completely clean each part of the yogurt production line without any residues.

CIP Cleaning System

The CIP cleaning system is commonly known as the in-situ cleaning system, which is widely used in high-mechanized food and beverage production enterprises such as beverages, dairy products, fruit juices, fruit pulps, jams, and wines. Cleaning in place is abbreviated as CIP, also known as cleaning positioning or cleaning in place (cleaning in place). In-situ cleaning refers to the use of high-temperature, high-concentration cleaning fluid without disassembling or moving the device to force the equipment and devices to clean the contact surface with food, and the cleaning of production equipment with stricter hygiene requirements , Purification.

Certifications

FAQ

|

Q

|

Are you trade or manufacturer?

|

|

|

|

|||

|

A

|

We are a factory with an international sales company specialized in support for global distributors.

|

|

|

|

|||

|

Q

|

Can you provide instant technical consulting services?

|

|

|

|

|||

|

A

|

We are able to discuss technical details and offer suggestions over the phone in English.

You can get the answers in minutes, instead of days. |

|

|

|

|||

|

Q

|

What's the difference between Ready-To-Ship and Customized products?

|

|

|

|

|||

|

A

|

Some of RTS standard products are in stock and ready to ship in 2-3 days.

We can also quick design and make the drawings for customer requirements, then begin the production. |

|

|

|

|||

|

Q

|

What is the payment terms?

|

|

|

|

|||

|

A

|

We accept Alibaba Trade Assurance Order, also can T/T and L/C.

|

|

|

|

|||

|

Q

|

How to choose the shipment way?

|

|

|

|

|||

|

A

|

It is according to the order quantity, delivery time, costs and customs policy etc. (Or decide by customers)

|

|

|

|

|||

|

Q

|

How about the after-sales service?

|

|

|

|

|||

|

A

|

Fast after-sales support. Our products have a one-year warranty and free permanent consulting services.

|

|

|

|

|||

Hot Searches