- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TELHOO

-

Power (kW):

-

5.5

-

Weight (KG):

-

600

-

Machine Type:

-

Pipe and Tube Bending Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw Material:

-

Pipe

-

Power:

-

HYDRAULIC

-

Color:

-

Customized color is available

-

Certification:

-

ce

Quick Details

-

Max. Bending Angle (Deg):

-

360

-

Bending Precision (Deg):

-

+-1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

TELHOO

-

Power (kW):

-

5.5

-

Weight (KG):

-

600

-

Machine Type:

-

Pipe and Tube Bending Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw Material:

-

Pipe

-

Power:

-

HYDRAULIC

-

Color:

-

Customized color is available

-

Certification:

-

ce

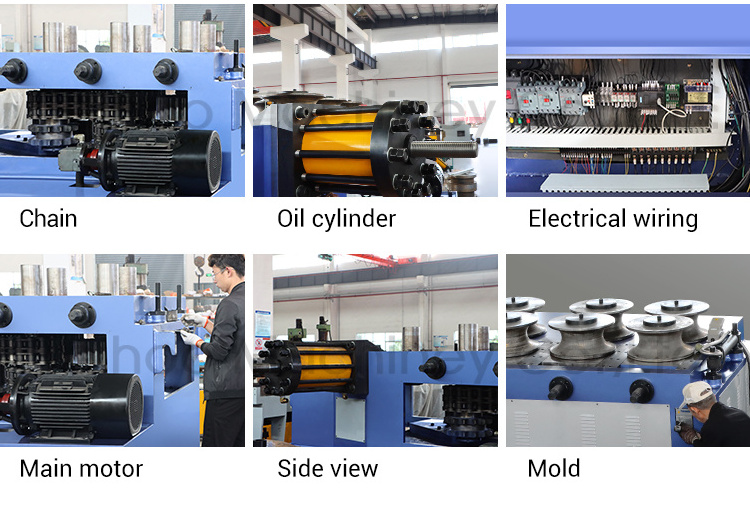

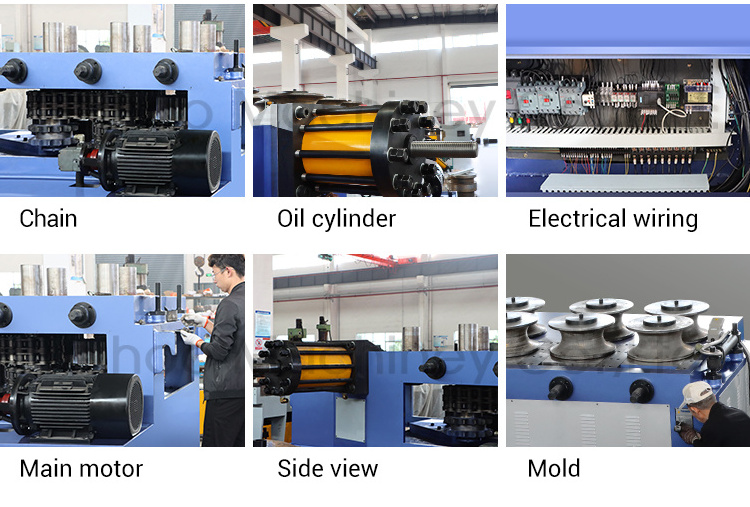

Product Description

Adapted material:steel pipe, stainless steel, copper pipe, aluminum pipe or profile.

Mechanical properties:

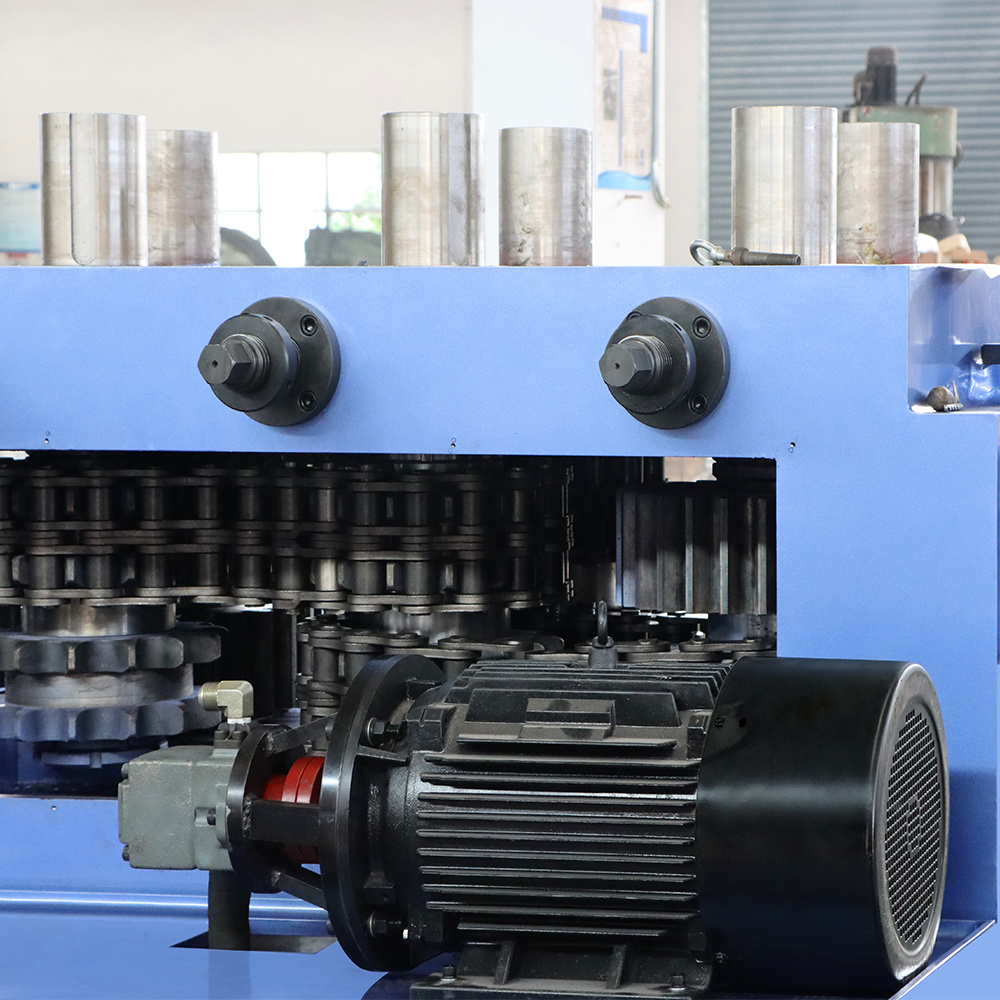

1.full-automatic transmission, compact structure, high reliability;

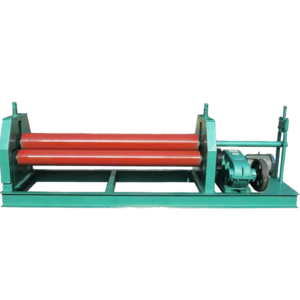

2.Three-roller transmission is not easy to slide. The thin-wall material also may be bended.

3.The rollers on both sides are distributed asymmetrically, reducing linear part.

4.Both the sides of the side roller can be used for feeding workpiece.

5.The double-footplate switch is equipped with emergent stopping system for operating conveniently.

6.This machine drives stably. Only regulate the side roller up and down can get round, arc or spirality of different curvatures.

7.If change mould’s shape, various metal shaped materials can be processed, like angle iron, flat steel, round steel or other special shaped material

8.It avoids the shortcomings of making super large tube bending mould while bending the large-radius shaped material, which is a necessary complementarity that series single-head, double-head tube benders can not reach.

9.Being of high speed and high benefit, this machine is adapted for middle or large batches production.

Mechanical properties:

1.full-automatic transmission, compact structure, high reliability;

2.Three-roller transmission is not easy to slide. The thin-wall material also may be bended.

3.The rollers on both sides are distributed asymmetrically, reducing linear part.

4.Both the sides of the side roller can be used for feeding workpiece.

5.The double-footplate switch is equipped with emergent stopping system for operating conveniently.

6.This machine drives stably. Only regulate the side roller up and down can get round, arc or spirality of different curvatures.

7.If change mould’s shape, various metal shaped materials can be processed, like angle iron, flat steel, round steel or other special shaped material

8.It avoids the shortcomings of making super large tube bending mould while bending the large-radius shaped material, which is a necessary complementarity that series single-head, double-head tube benders can not reach.

9.Being of high speed and high benefit, this machine is adapted for middle or large batches production.

Specification

|

Properties

|

Spec.

|

|

Max diameter of bended tube

|

Φ60×2

|

|

Min. bending diameter

|

Φ480

|

|

Rolling speed

|

4m/min

|

|

Diameter of mould

|

Φ250

|

|

Motor power

|

5.5kw

|

|

Weight

|

1200kg

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches