- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

High

-

Power:

-

2.2KW

-

Dimension(L*W*H):

-

1100*1100*1300mm

-

Processing profile height:

-

140mm

-

Total group angular pressure:

-

48KN

Quick Details

-

Brand Name:

-

Zhenfei

-

Voltage:

-

380V /220V 50Hz

-

Weight:

-

550 kg

-

Production Capacity:

-

High

-

Power:

-

2.2KW

-

Dimension(L*W*H):

-

1100*1100*1300mm

-

Processing profile height:

-

140mm

-

Total group angular pressure:

-

48KN

Product Paramenters

|

Model

|

|

LZJA120A

|

|

|

|||

|

Power supply

|

|

380V / 220V 50Hz

|

|

|

|||

|

Motor power

|

|

2.2KW

|

|

|

|||

|

Air consumption

|

|

2L / min

|

|

|

|||

|

Total group angular pressure

|

|

48KN

|

|

|

|||

|

Processing profile height (max.)

|

|

140 mm

|

|

|

|||

Products Description

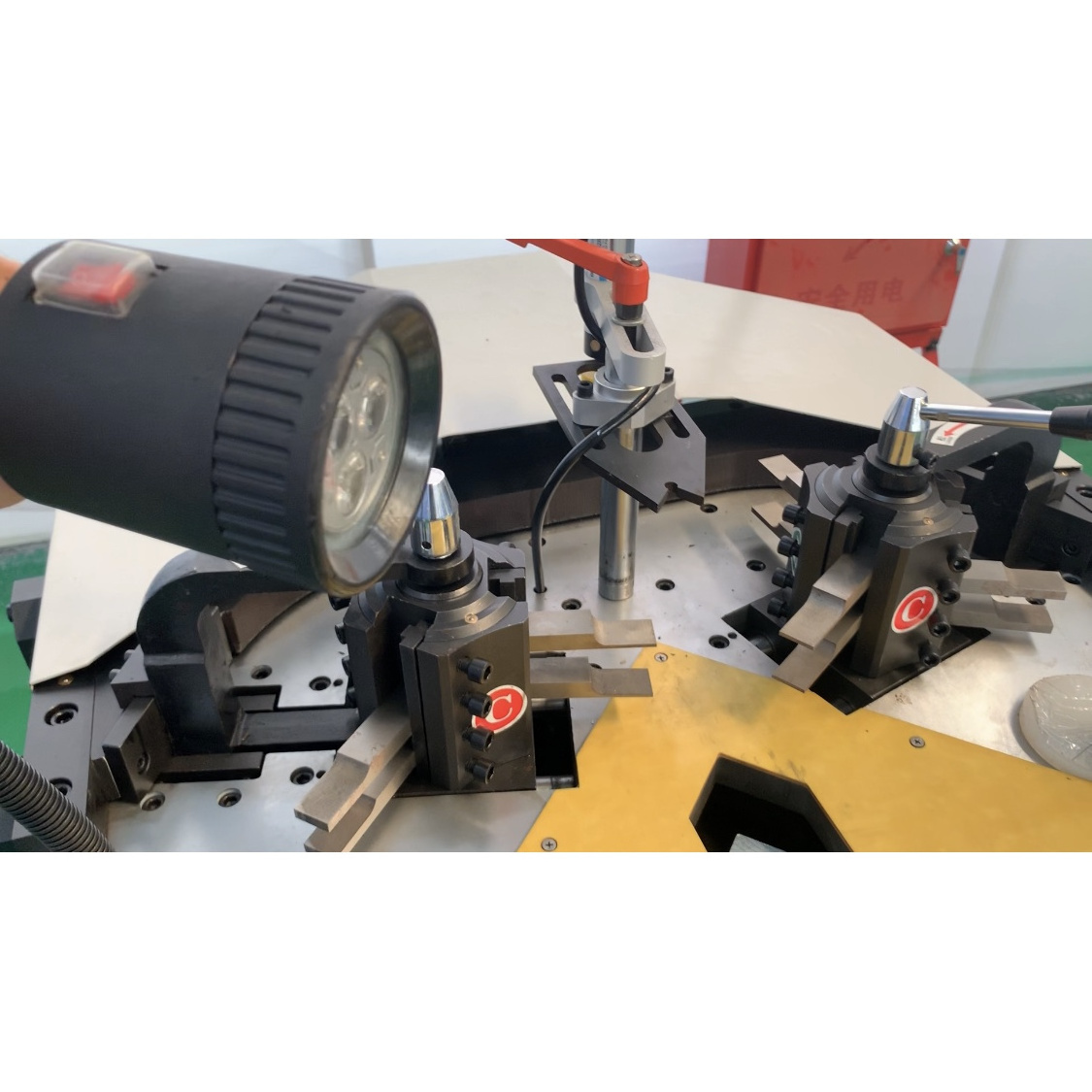

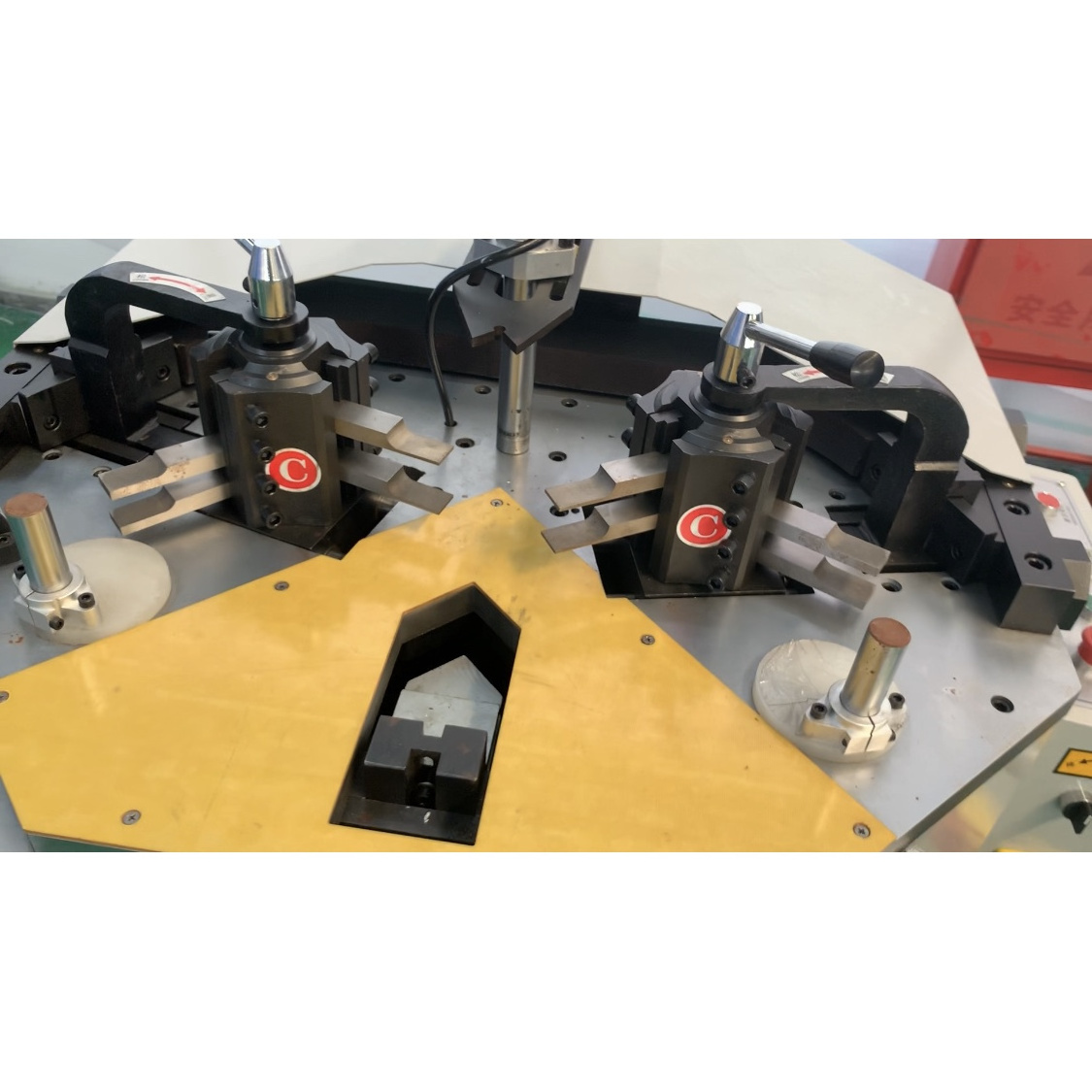

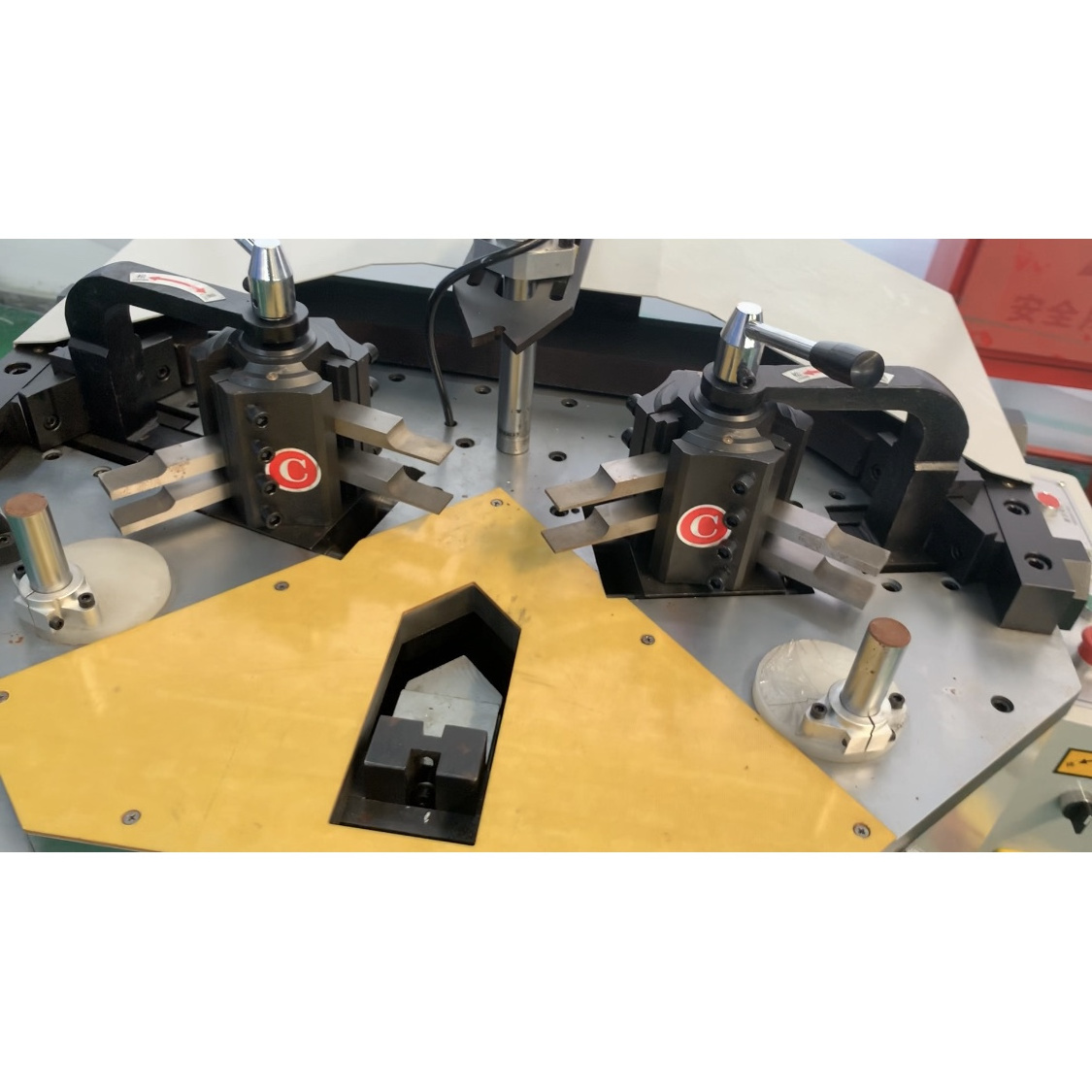

LZJA3-120A group corner machine is a special equipment for high-grade aluminum doors and windows production, suitable for 90-degree angle connection of angle-coded aluminum doors and windows.

Features:

Magazine-type design, can install three sets of profile processing tools at the same time, saving tool changing time and increasing work efficiency The tool change method is rotary tool change and lock, and the tool change speed is 3 seconds. After the common tools are installed, they can be used for a long time.

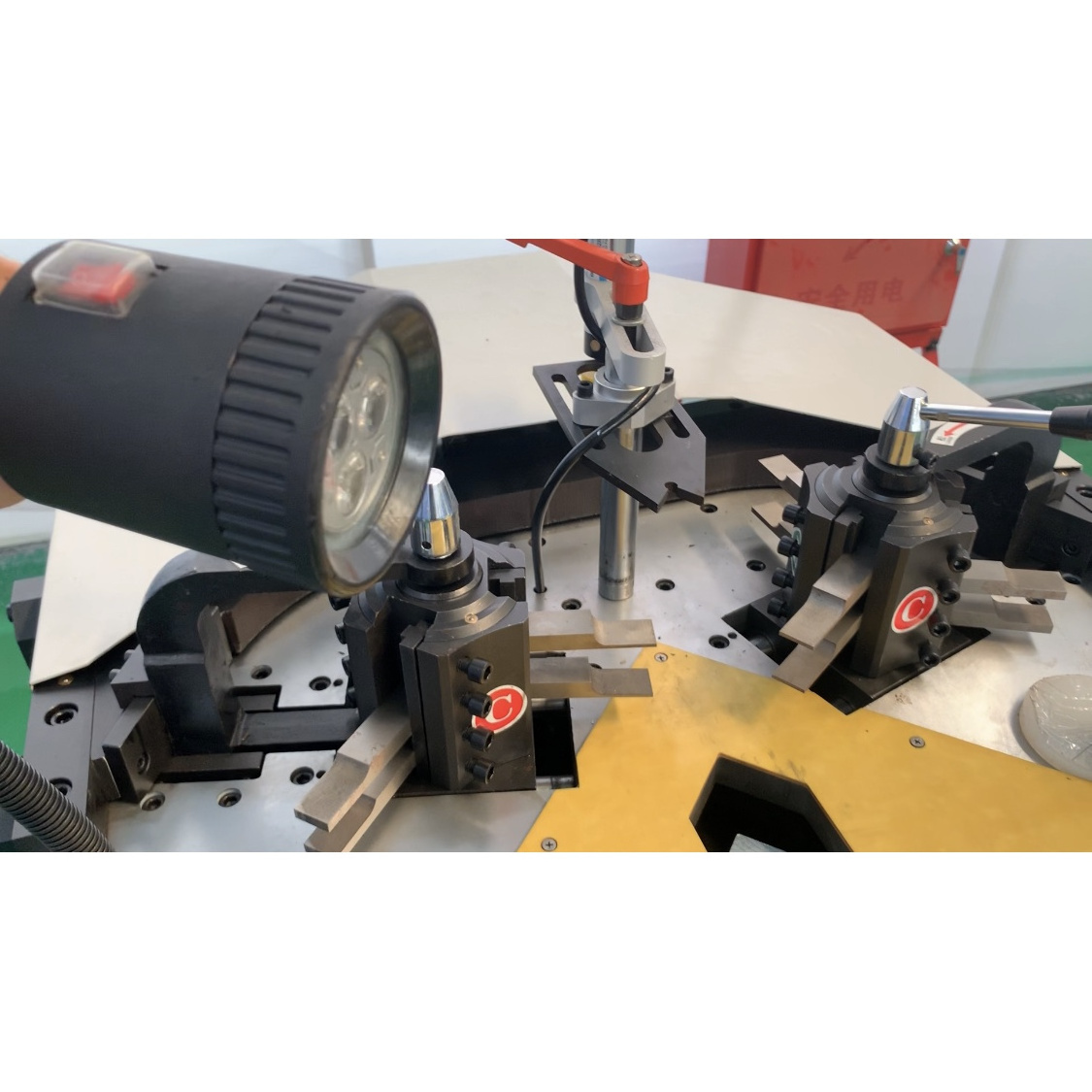

The adjustment method is handwheel adjustment. The handwheel is matched with a counter for precise adjustment. Remember the value when processing various profiles. When changing the profile, adjust to the required value. This completes the position adjustment.

Positioning is pneumatic lifting and electric adjustment.

Pneumatic lifting increases the convenience of discharging and reclaiming the profile during work.

Electric adjustment, eliminating the disassembly time of the positioning plate when changing the profile. The positioning plate can be adjusted electrically up and down.

The distance between the front working area and the corner of the group is very close, which is suitable for workers of various heights.

Optimized the circuit design to minimize the cylinder stroke when no work is done. Each group corner processing cycle can be one-third faster than the same model. To save labor, time and power.

Mechanical transmission structure is optical axis and copper sleeve. The most commonly used sliding structure in mechanical structures. Minimal wear under prolonged and high load working conditions.

Recommend Products

Hot Searches