- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CYG-1590

-

Thickness:

-

customized

-

Size:

-

customized

-

Color:

-

gray,black,white

-

Density:

-

25-330 kg/m3

-

Tensile Strength:

-

0.15~0.2 Mpa

-

Elongation at break:

-

100%~110%

-

Tearing Strength:

-

1.2~1.3 KN/m

-

Size change rate:

-

-6%`-8%

-

Water Absorption(23degree,24h):

-

<0.5%

-

Thermal conductivity:

-

<0.040 w/m.k

-

Type:

-

Extruded

-

Raw material:

-

ldpe

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CYG

-

Model Number:

-

CYG-1590

-

Thickness:

-

customized

-

Size:

-

customized

-

Color:

-

gray,black,white

-

Density:

-

25-330 kg/m3

-

Tensile Strength:

-

0.15~0.2 Mpa

-

Elongation at break:

-

100%~110%

-

Tearing Strength:

-

1.2~1.3 KN/m

-

Size change rate:

-

-6%`-8%

-

Water Absorption(23degree,24h):

-

<0.5%

-

Thermal conductivity:

-

<0.040 w/m.k

-

Type:

-

Extruded

-

Raw material:

-

ldpe

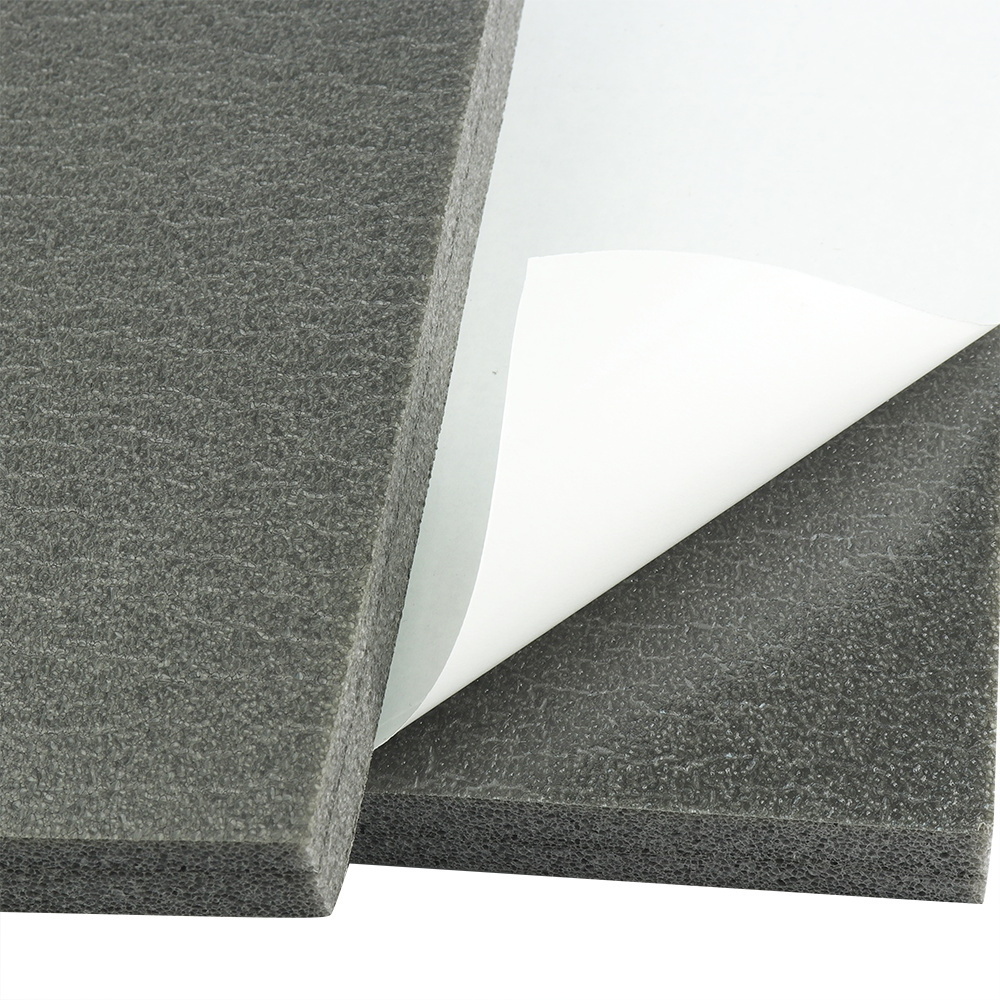

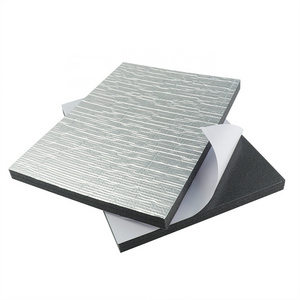

| Cross-linked Closed Cell Polyethylene Foam |

Polyethylene foam is a durable, lightweight, resilient, closed-cell material. It is often used for packaging fragile goods due to its excellent vibration dampening and insulation properties. It also offers high resistance to chemicals and moisture.

Before quote to us,please provide the following information:

Density,thickness,color,quantity and so on.They can all customized.

| The Spec. of XPE Foam |

|

Test item |

Items |

|||||||

|

5 Times |

8 Times |

10 Times |

15 Times |

20 Times |

25 Times |

30 Times |

35 Times |

|

|

Density kg/m3 |

200±30 |

125±15 |

100±10 |

66.7±8 |

50±6 |

40±4 |

33.3±3 |

28.6±2 |

|

Shore Hardness |

60~70 |

50~60 |

45~50 |

35~45 |

30~35 |

25~30 |

18~25 |

13~18 |

|

Water absorbtion (23℃±2℃,24h)g/cm2 |

≤0.02 |

≤0.02 |

≤0.03 |

≤0.03 |

≤0.04 |

≤0.04 |

≤0.05 |

≤0.05 |

|

Heat conductivity K value w/m.k |

≤0.092 |

≤0.082 |

≤0.072 |

≤0.062 |

≤0.053 |

≤0.047 |

≤0.041 |

≤0.038 |

| The Spec. of IXPE Foam |

|

Test item |

Items |

|||||||

|

5 Times |

8 Times |

10 Times |

15 Times |

20 Times |

25 Times |

30 Times |

35 Times |

|

|

Density kg/m3 |

200±30 |

125±15 |

100±10 |

66.7±8 |

50±6 |

40±4 |

33.3±3 |

28.6±2 |

|

Shore Hardness |

60~70 |

50~60 |

45~50 |

35~45 |

30~35 |

25~30 |

18~25 |

13~18 |

|

Water absorbtion (23℃±2℃,24h)g/cm2 |

≤0.02 |

≤0.02 |

≤0.03 |

≤0.03 |

≤0.04 |

≤0.04 |

≤0.05 |

≤0.05 |

|

Heat conductivity K value w/m.k |

≤0.095 |

≤0.084 |

≤0.073 |

≤0.065 |

≤0.055 |

≤0.045 |

≤0.040 |

≤0.040 |

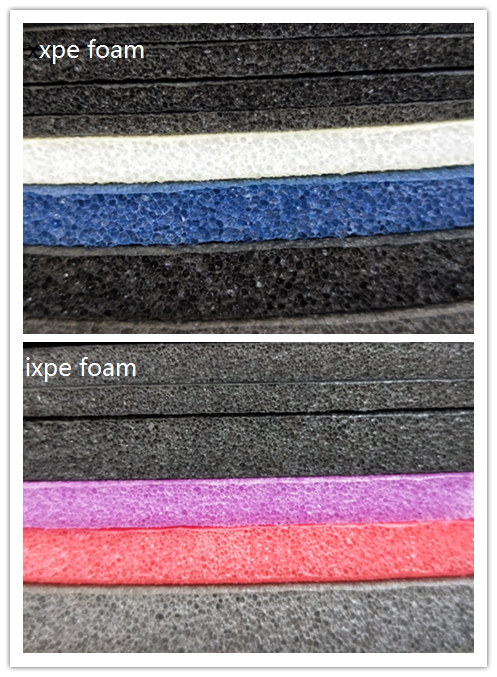

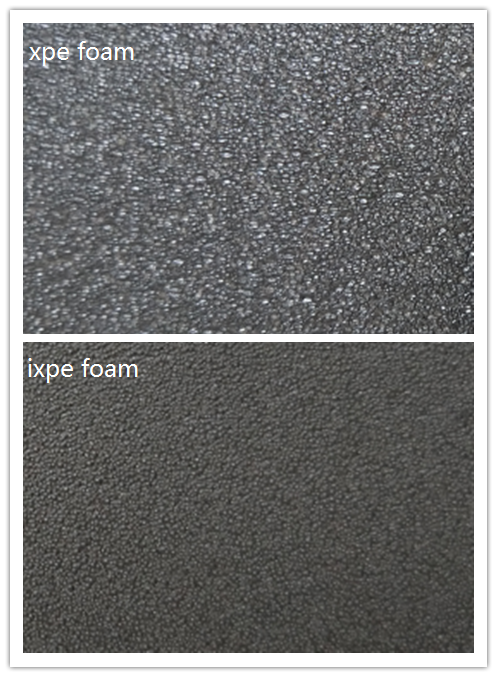

| Polyethylene Foam Structure |

Polyethylene foam is closed-cell, meaning it consists of cells so tightly packed together that it gives the appearance of one uniform structure.

The reality is that the individual cells within polyethylene foam do not physically connect to one another.

This cellular formation is similar to fish caught in a fisherman's net.

From a critical distance, the net appears to be one massive object.

However, upon closer examination, it becomes apparent that there is numerous individual fish packed tightly together that the result is the aforementioned appearance of singularity.

Cell: Surface:

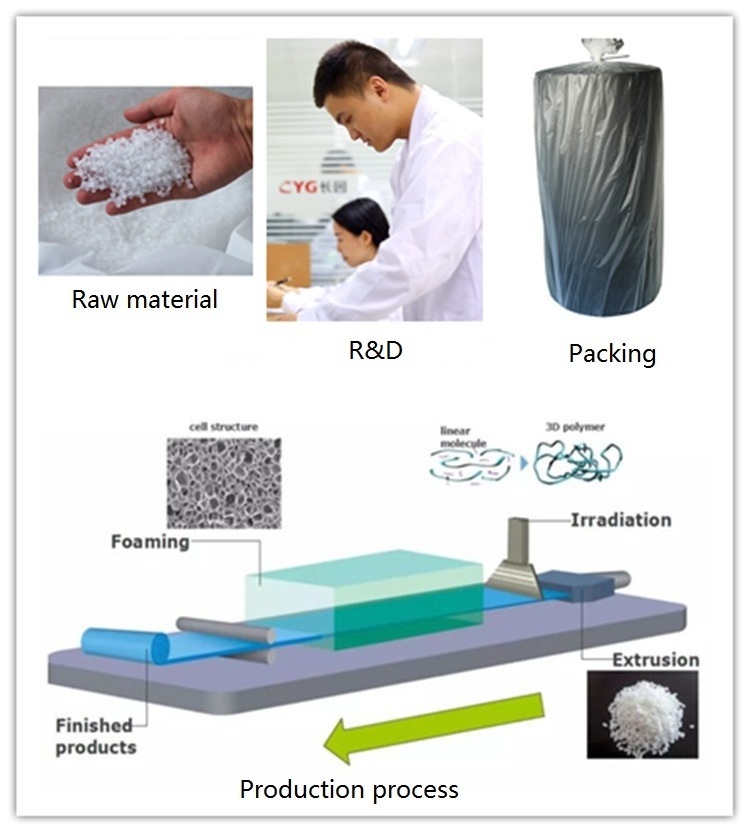

Extrusion→Irradiation(IXPE FOAM)→Foaming→Roll up→Lamination→Die-cutting→Qulity testing→Packing→Loading

| Application |

Automotive

Main applications: Interior materials such as cushioning material for head liners, trunk mats, and door trim.

Building and Construction

Insulation, moisture-proof or water-proof roofing materials, materials for gap adjustment, joint sealants for civil engineering and construction work, base materials, curing sheets, and antifreeze materials for the prevention of mud pumping on roads or rail roads.

Industrial thermal insulation

Insulation materials for air conditioning,HVAC or refrigeration equipment, anti-freezing materials for water pipes, heat insulation materials for pipes and bathtubs, moisture-proof materials for sinks, tape base materials, and gaskets.

Packaging

The packaging industry uses the material to protect products because it absorbs energy and can act achieve different levels of cushioning protection depending on the exact density of the foam.

Sports, leisure and consumer goods

Sports equipment such as beat boards for swimming and gym mats, and consumer goods such as bath equipment, kitchen equipment, and backing materials for mats.

Conductive & ESD

Ixpe conductive foam tray

IT Rerated

LCD packing and sealing

Medical

Medical pads

Polyethylene foam, also known as PE, PEF, Ethafoam & Polyfoam, is a semi-rigid, closed-cell type of foam with a near-infinite amount of applications due to the following characteristics:

- Thermal conductivity

- Recyclability

- Cushioning

- Flexibility

- Durability

- Buoyancy

- Odorless

- Lightweight

- Non-dusting

- Non-abrasive

- Cost/labor efficient

- High load bearing capacity

- Sound transmission control

- Dimensional stability

- Uniform cell structure

- Shatter proof

- Tear/puncture-resistant

- Impact/shock/vibration absorption

- Excellent compressive creep properties

- Bacteria/chemical/grease/mold/oil /solvent-resistant