- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

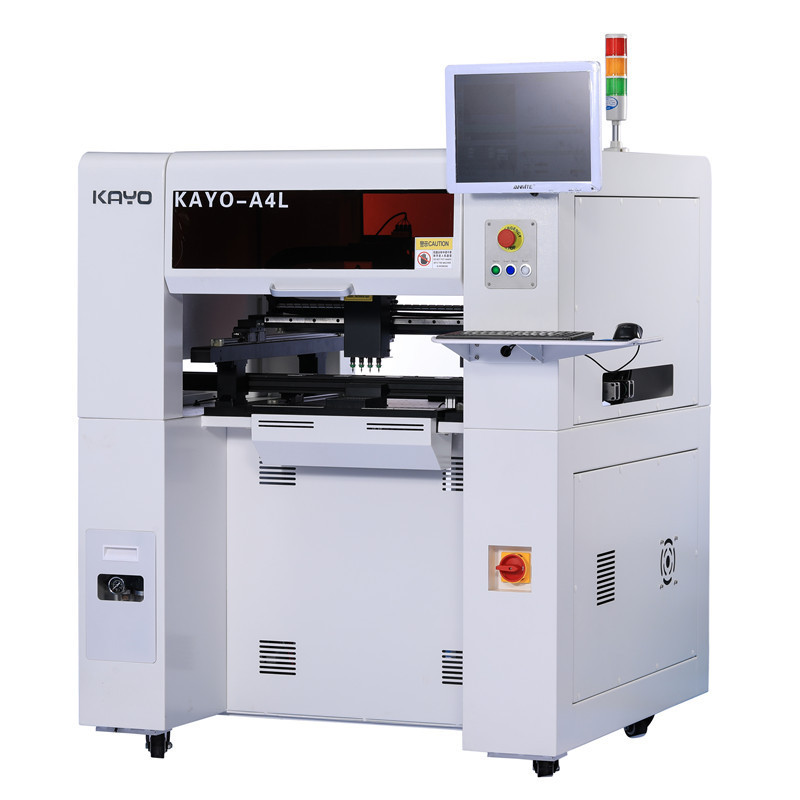

KAYO-A4L High Speed 4 heads Smt Pick And Place Machine Automatic

-

Weight:

-

450KGS

-

Power Supply:

-

AC220V 50Hz / AC110V 60Hz

-

Package:

-

Wooden Box Filled

-

Quality:

-

100% Tested

-

Mounting speed:

-

6000cph (Highhest -7200cph)

-

Applicable Components:

-

0402-5050 Sop Qfn BGA

-

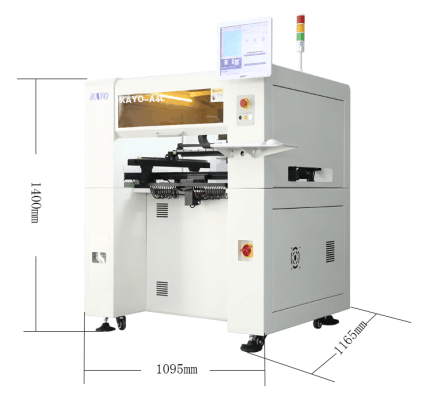

Dimension:

-

1095MM(L)*1165MM(W)*1400MM(H)

-

Application:

-

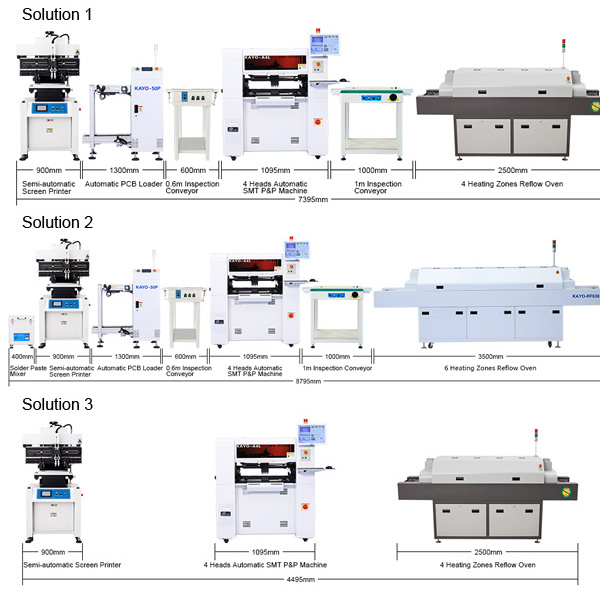

SMT PCB Assembly Production Line

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KAYO

-

Model Number:

-

KAYO-A4L

-

Product name:

-

KAYO-A4L High Speed 4 heads Smt Pick And Place Machine Automatic

-

Weight:

-

450KGS

-

Power Supply:

-

AC220V 50Hz / AC110V 60Hz

-

Package:

-

Wooden Box Filled

-

Quality:

-

100% Tested

-

Mounting speed:

-

6000cph (Highhest -7200cph)

-

Applicable Components:

-

0402-5050 Sop Qfn BGA

-

Dimension:

-

1095MM(L)*1165MM(W)*1400MM(H)

-

Application:

-

SMT PCB Assembly Production Line

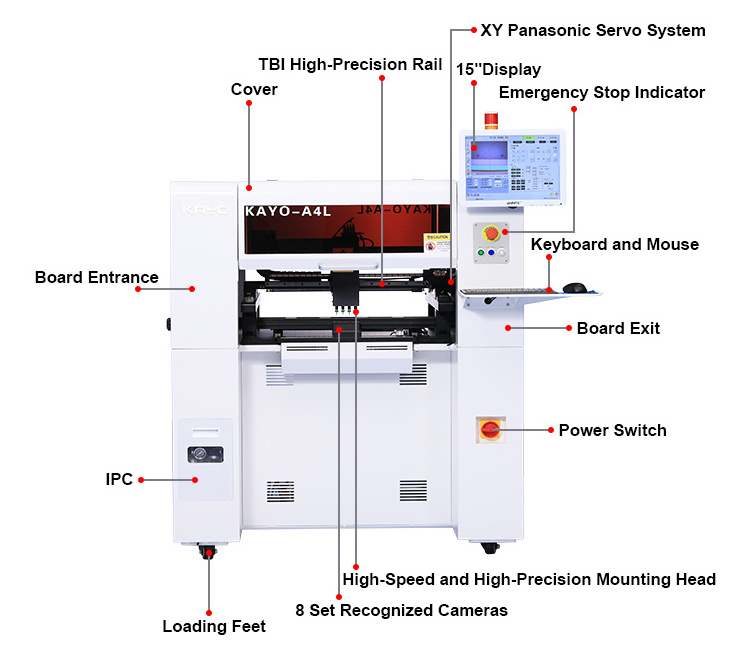

KAYO-A4L

4 Heads Automatic SMT P&P Machine

Product Dimensions:

Product Details:

| Application For | |

| Application Area | Application Industry |

| Personal Entrepreneurship | Household Electrical Appliance Industry |

| Laboratory Proofing | Automotive Electronics |

| Mass Production | Power Diver |

| Processing of The Third Party | LED Lighting |

| R&D Customization | Security Instruments and Meters |

| Scientific&Research | Intelligent Contorl |

| Efficient Teaching | Consumer Electronics |

| Logistics Network | |

| Military Industry | |

Product Advantages:

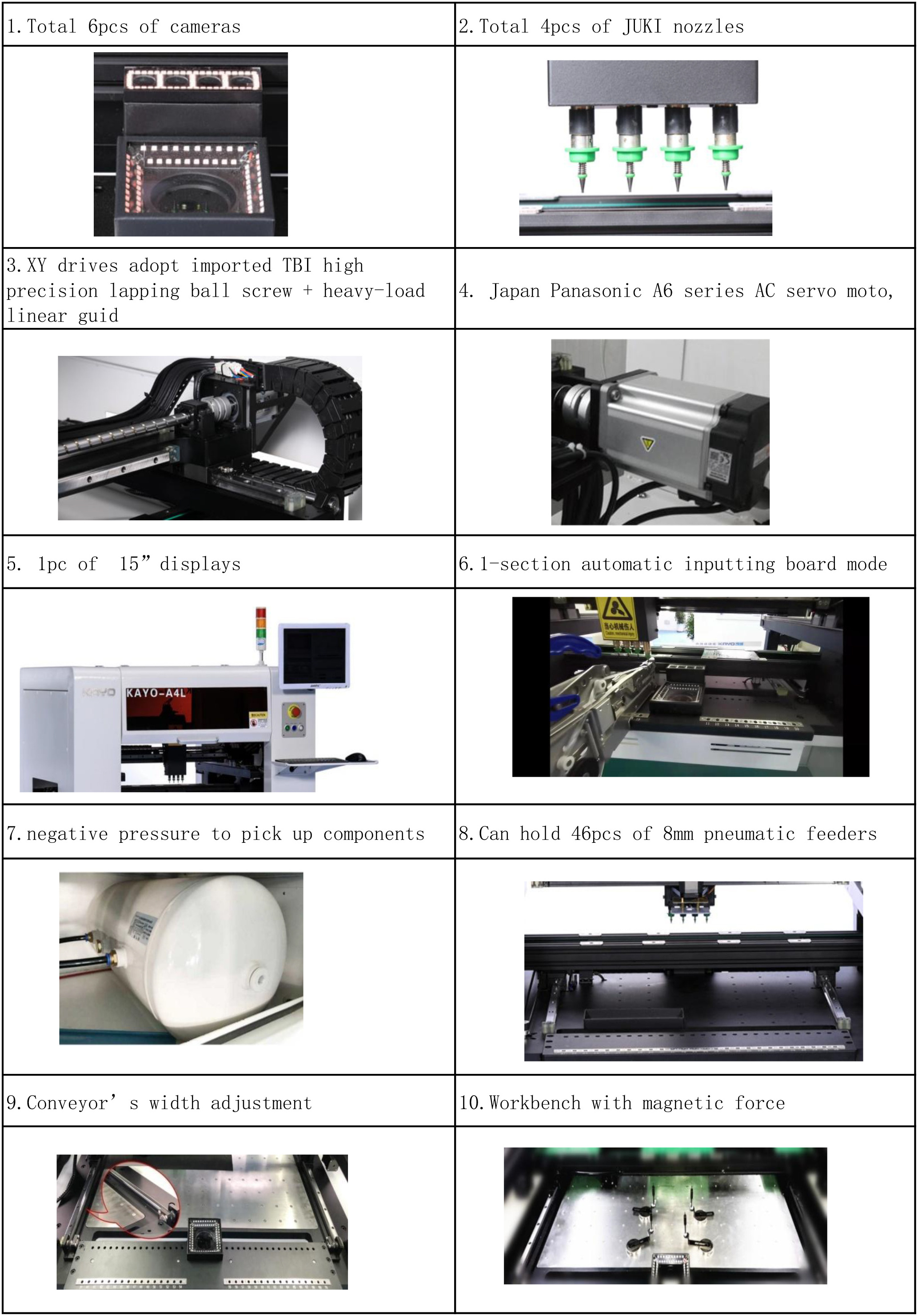

1.Optimized multi-functional conveyor (best positioning + no impact stopping), adopt a laser sensor rather than mechanical stopper to position. No relyon the PCB board size, shape, achieve the best positioning and no impact stop.

2.High Precision: Equipped with 6pcs of cameras: 1pc of Mark, 1pc of high precision, and 4pcs of high-speed recognition cameras, could effectively mount 0402-5050 components, beads, diodes, transistors, SOP, 45mm*45mm range pin pitch ≥0.3mm chip QFP-256, BGA et c .

3. Fast Speed: the max. mounting speed: 8000CPH, average mounting speed: 6000CPH.

4.Strong Stability : Panasonic Servo Motor and Drive, TBI precise linear guide and ball screw, Japan Vacuum generator, JUKI high-precise nozzles, automatic feeding integrated system and high-configuration IPC - High precision, strong stability, promise 24-hour mounting stably.

Product Specification:

| Feeder No. | 46(Front 20, rear 26) | Mounting Heads | 4(No need to change Nozzle) |

| tray quantity | support 4 pcs | Positioning Accuracy | 0.01mm |

| Average Power | 600W | Power Supply | 220V, 50Hz |

| Nozzle Buffering Range | 5.0mm | Compressed Air | 0.5-06Mpa |

| Driving Motor | Panasonic servo motor | Max. Circuit Board Area | 480*300mm |

| XY Max. Movement Range | 556*680mm | Z Axis Max. Movement Range | 20mm |

| Product Weight | 450KGS | Dimensions | 1095*1165*1400mm |

| Placement Mode | Manual, semi-automatic, fully-automatic | operation window | Single display operation |

| Rail Guide Adjusting Method | Manual + Automatic | Alarm when open the cover | Reducing speed or out of service |

| Motion Drive System | Panasonic High speed DPS driver | XY axis movement model | Intelligent curve acceleration and deceleration linear linkage |

| Belt Type Feeder | 8/12/16/24mm feeders, stick feeder | ||

| Max. Mounting Speed | 8000CPH (Visual) | ||

| Average Mounting Speed | 6000CPH (Visual) | ||

| XYZ Drive Guide Rail | TBI High-precision heavy-duty straight-line guide rail | ||

| Nozzle Vacuum Source | High-speed on-off vacuum generator with vacuum damage | ||

| Operating System | Support Windows XP, Win7 operating system | ||

| Component Angle | 0~360°, synchronized rotation in motion | ||

| Board Input Method | Automatically connect loader and position PCB transmission | ||

| Visual Display | 1pc industrial control display ratio 4:3, resolution1024X768 | ||

| Programming Mode | Point-to-point programming, visual programming, PCB file coordinates inputting, etc. | ||

| Recognition Camera No. | 1pc of Mark recognition camera, 4 pcs of high speed recognition camera, 1 pc of 5 million high-precision recognition camera | ||

| Mount optimization | Automatic program optimization.After the installation, the production can continue without waiting for reset | ||

| Shortcut button | off-line/restoration/automatic operation /remove the alarm | ||

| Automatic on-line | Can automatically connect front and rear end with signal equipment | ||

| Applicable Mounting Range: Suitable for 0201, 0402, 0603, 0805, 1206, LED lamp beads, diodes, transistors, SOT, 40mm*40mm range pin pitch ≥0.3mm QFP, BGA etc. | |||

KAYO main products

1.Pick and place machines

Pick and place machines parameters

| Machine Name | KAYO-2DV-25S | KAYO-A4 | KAYO-A4L | KAYO-1706-3DSG (KAYO-A6L) | KAYO-A8L | KAYO-S600 | |

| Type | Vertical | ||||||

| Mounting Heads | 2 | 4 | 4 | 6 | 8 | 6 | |

| Feeder No. | 25 | 46 | 46 | 60 | 70 | 82 | |

| Max. Mounting Speed | off visual (CPH) | 6000 | 7000 | 8000 | 13000 | 15000 | 16000 |

| on visual (CPH) | 5000 | 5000 | 6000 | 10000 | 12000 | 14000 | |

| PCB Size | Min.(W*Lmm) | 50*50 | |||||

| Max.(W*Lmm) | 295*420 | 300* 480 | 300* 480 | 370* 650 | 380* 650 | 380* 650 | |

| Camera | Total | 2 | 6 | 6 | 8 | 10 | 9 |

| Mark | 1 | 1 | 1 | 1 | 1 | 1 | |

| High-speed | 1 | 4 | 4 | 6 | 8 | 6 | |

| High-precision | 0 | 1pc of 5million | 1pc of 8million | ||||

| Visual correction | 0 | 0 | 0 | 0 | 0 | 1 | |

| Driving Motor | Progressive motor | Panasonic servo motor | |||||

| Motion Drive System | High speed digital high voltage driver | Panasonic High speed DPS driver | |||||

| Positioning Accuracy | 0.01mm | ||||||

| Support Feeding Method | 8/12/16/24/32/44mm Pneumatic and electric feeder ,vibration feeder ,tube feeding, tray IC | ||||||

| Applicable Mounting Range | Min. | 0402 | 0201 | ||||

| Max. | 15*15mm | 45mm*45mm range pin pitch ≥0.3mm SSOP,QFP, BGA etc. | |||||

| Weight(kgs) | 100 | 350 | 450 | 450 | 550 | 880 | |

| Dimensions(mm) | 1050*850*660 | 1180*1080*880 | 1095*1165*1400 | 1335*1230*1420 | 1500*1280*1410 | ||

2.Screen printer

Screen Priners parameters

| Machine name | KAYO-P1000 | KAYO-5088 | KAYO-5088C | KAYO-5088L | KAYO-YS1 | KAYO-450 | KAYO-600 | |

| Type | Manually | Semi-auto | Full automatic | |||||

| Max. PCB Size(mm) | 250*400 | 400*300 | 600*320 | 1200*300 | 400*300 | 450*350 | 610* 350 | |

| Printing Table Size(mm) | 300*400 | 500*320 | 700*350 | 1250*320 | ||||

| Stencil Frame Size | Min.(mm) | 470*370 | 470*370 | 420*520 | ||||

| Max.(mm) | 370*470 | 600*320 | 950*736 | 1500*550 | 600*550 | 737*737 | 800*800 | |

| Squeegee Length | Standard 200mm (Could lengthen according to clients’ request) | |||||||

| Squeegee Speed | Manually Controlled | 0-100mm/s | 0- 200 mm/s | |||||

| PCB Thickness(mm) | 0.2-3 | 0.4-5 | 0.6-14 | |||||

| Printing Accuracy(mm) | ±0.01 | ±0.02 | ±0.1 | |||||

| Repeat Precision(mm) | ±0.01 | ±0.02 | ±0.05 | |||||

| Machine Dimension(L*W*Hmm) | 540*380*390 | 900*1100*1680 | 1800*900*1680 | 1450*1200*1680 | 1140*1400*1480 | |||

| Weight(kgs) | 20 | 150 | 160 | 180 | 500 | 1000 | 1200 | |

3.Reflow oven

Reflow oven parameters

| Machine name | KAYO-RF330 | KAYO-RF530 | KAYO-RF430 | KAYO-RF630 | KAYO-835 | KAYO-8845 | KAYO-610L | KAYO-820L | KAYO-800L | |

| Type | Desktop | Vertical | ||||||||

| Heating Zone | upper | 3 | 3 | 4 | 6 | 8 | 8 | 6 | 8 | 8 |

| down | 0 | 2 | 4 | 6 | 8 | 8 | 6 | 8 | 8 | |

| PCB Max. Width | 300 | 350 | 450 | 300 | 400 | |||||

| Transmission type | mesh | Mesh (Can customize mesh + rail guide) | Mesh + rail guide | |||||||

| Cooling zone | 2 | |||||||||

| Heating zone length(mm) | 1000 | 960 | 1400 | 2200 | 3200 | 3150 | 2050 | 2700 | 3000 | |

| Temperature control type | Panel Button + PID Close Loop | Panel Button +PID closed-loop (Can customize PC + PID) | PC +PID closed-loop | |||||||

| upper furnace opening method | Manually Open | Double electric cylinder jacking | ||||||||

| Dimensions(L*W*H mm) | 1500*610 *670 | 1700*710 *650 | 2500*612 *1220 | 3600*700 *1220 | 4200*800 *1320 | 4600*1000 *1420 | 3600*1200 *1450 | 4600*1200 *1450 | 5050*1350*1550 | |

| Weight(kgs) | 120 | 150 | 300 | 500 | 900 | 1100 | 800 | 1000 | 2200 | |

4.Other Accessories