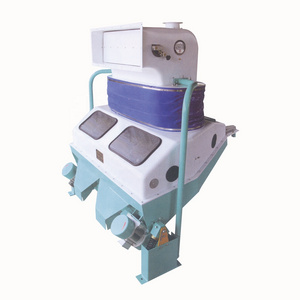

Feeding and Air-suction.

Put the seeds into feeding hopper, through bucket elevator the seed are transported to the front and rear air-suction screen, destoner device and then drop to the first sieve. The Air suction volume is adjustable by hand very easy and accurate separation without loss of seeds in the air flow.

In the air-suction, the seeds are sorted by weight, the dust and lightest impurity are carried upwards with the air stream and fall down in the cyclone duster. Parts of stones will be sorted by a simple destoner, The seed will fall down in the firstly sieve.

Sieving(4 layers sieve).

The overflow impurity which large than good seeds from first sieve leaves the machine and discharge to the outlet. The seeds dropped through fall on the second sieve for the next sieving. The overflow of the second sieve leaves the machine at the outlet, The seeds dropped through fall on the third and bottom sieve, which can grade the seeds according to thickness or width. The impurities that was smaller than the desired size of seed drop through the bottom sieve and are eliminated through outlet. The overflow seeds of third and bottom sieve have the desired size and are transported to the front outlet of machine.