- Product Details

- {{item.text}}

Quick Details

-

Shape:

-

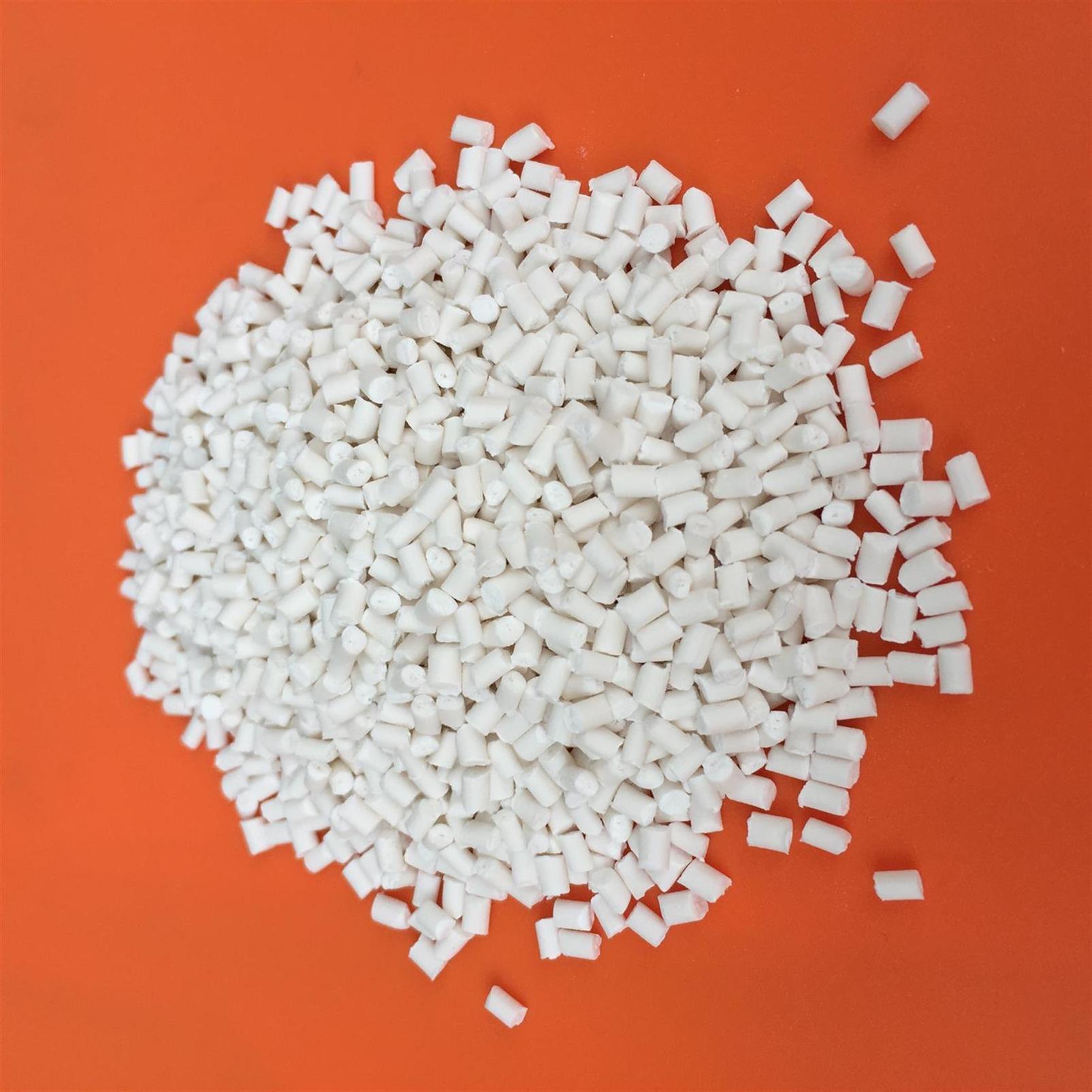

granules

-

Product Name:

-

Flame retardant Masterbatch

-

Color:

-

white/Customized

-

Usage:

-

2%-6%

-

Certification:

-

ISO9001 ROHS

-

Advantage:

-

Fluidity

-

Carrier:

-

PP PE ABS PET PVC

-

Color intensity:

-

95-105%

-

Movability resistance:

-

6-8

-

Chromatic Aberration:

-

≤0.5

Quick Details

-

Place of Origin:

-

Guangdong,China

-

Brand Name:

-

ColorMaster

-

color:

-

customized

-

Shape:

-

granules

-

Product Name:

-

Flame retardant Masterbatch

-

Color:

-

white/Customized

-

Usage:

-

2%-6%

-

Certification:

-

ISO9001 ROHS

-

Advantage:

-

Fluidity

-

Carrier:

-

PP PE ABS PET PVC

-

Color intensity:

-

95-105%

-

Movability resistance:

-

6-8

-

Chromatic Aberration:

-

≤0.5

Video Description

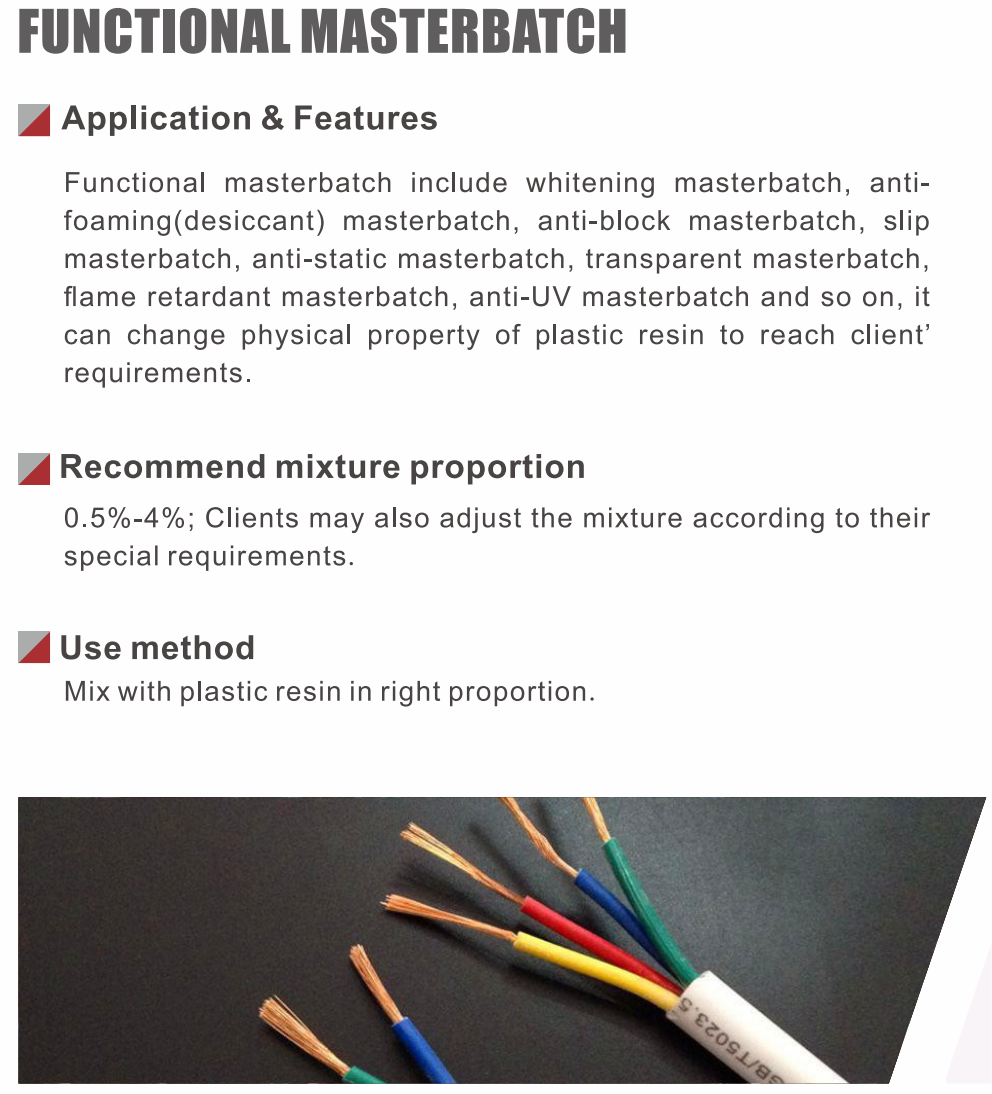

toner content Anti-UV Masterbatch Additive extruded pipes functional Anti-UV Masterbatch Additive

Products Description

Anti-UV Masterbatch :

|

MFI:

|

20-30g/10mins

|

|

Appearance:

|

White granules

|

|

Weathering(level)

:

|

4-6

|

|

Melting Point:

|

≥

130

℃

|

|

Movability resistant(level)

:

|

6-8

|

|

Recommend addition

:

|

1-5%

|

|

Heat-resistant

:

|

≥5

|

Specifications

Using Anti-UV masterbatch

More Products

Certifications

Our Advantages

AOUT US

We have

two manufacturing factories

, one factory to produce black masterbatch and another one to produce white masterbatch, color masterbatch, filler masterbatch and other masterbatches.

The most advantage is that this

can completely avoid color mixture

and

assure the best quality!

FAQ

Q1.What kind of plastic is your masterbatch suitable for?

Perfectly suit: PE/ PP/ PVC/PC/ ABS/ PET/ PS/ EVA/AS/TPE etc.

Q2.How do you guarantee quality?

Q3.Why choose us?

Q4.What services can you provide?

Q5.How to get a quotation?

Q2.How do you guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

Q3.Why choose us?

1.One-stop solution for customization

2.20+ years experiences

3.Two Factories to avoid color MIXTURE

4.Cost

savings--Minimize formulation costs&enhancing end-product performance

5.24-hours Professional technical services

6.Ship within a

WEEK & FREE sample

Q4.What services can you provide?

1.Delivery Terms: FOB,FCA,CFR,CIF,DDU,DDP etc.

2.Payment Terms: Trade Assurance,T/T,L/C,Paypal,Credit Card,etc.

3.Languages:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian etc.

3.Languages:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian etc.

Q5.How to get a quotation?

There are 2 ways:

1.Send us a sample

2.Inform us your specific requirement:

a) Color(Pantone number)

b) Pigment concentration

b) Pigment concentration

c) Final products application

d) Polymer carrier

e) Heat fastness level

f) Light fastness level

g) MFI

3.Get our regular products price list for your reference if you are not very clear

3.Get our regular products price list for your reference if you are not very clear

Recommend Products

Hot Searches