- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FAYON

-

Dimension(L*W*H):

-

1940mm*1350mm*630mm

-

Weight:

-

190 KG

-

TYPE:

-

FY-1600DA

-

Max laminating width:

-

1620mm

-

Max laminating thickness:

-

35mm

-

Max Working Speed:

-

10m/min

-

Roller Material:

-

130mm Heat resistant silicone(60℃)

-

Heating Function:

-

Room-60℃

-

Motor Power:

-

120w

-

Machine Dimensions:

-

1940mm*1350mm*630mm

-

Net Weight:

-

190kg

-

Gross Weight:

-

210kg

Quick Details

-

Packaging Type:

-

Cartons

-

Packaging Material:

-

Wood

-

Driven Type:

-

Pneumatic

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FAYON

-

Dimension(L*W*H):

-

1940mm*1350mm*630mm

-

Weight:

-

190 KG

-

TYPE:

-

FY-1600DA

-

Max laminating width:

-

1620mm

-

Max laminating thickness:

-

35mm

-

Max Working Speed:

-

10m/min

-

Roller Material:

-

130mm Heat resistant silicone(60℃)

-

Heating Function:

-

Room-60℃

-

Motor Power:

-

120w

-

Machine Dimensions:

-

1940mm*1350mm*630mm

-

Net Weight:

-

190kg

-

Gross Weight:

-

210kg

Products Description

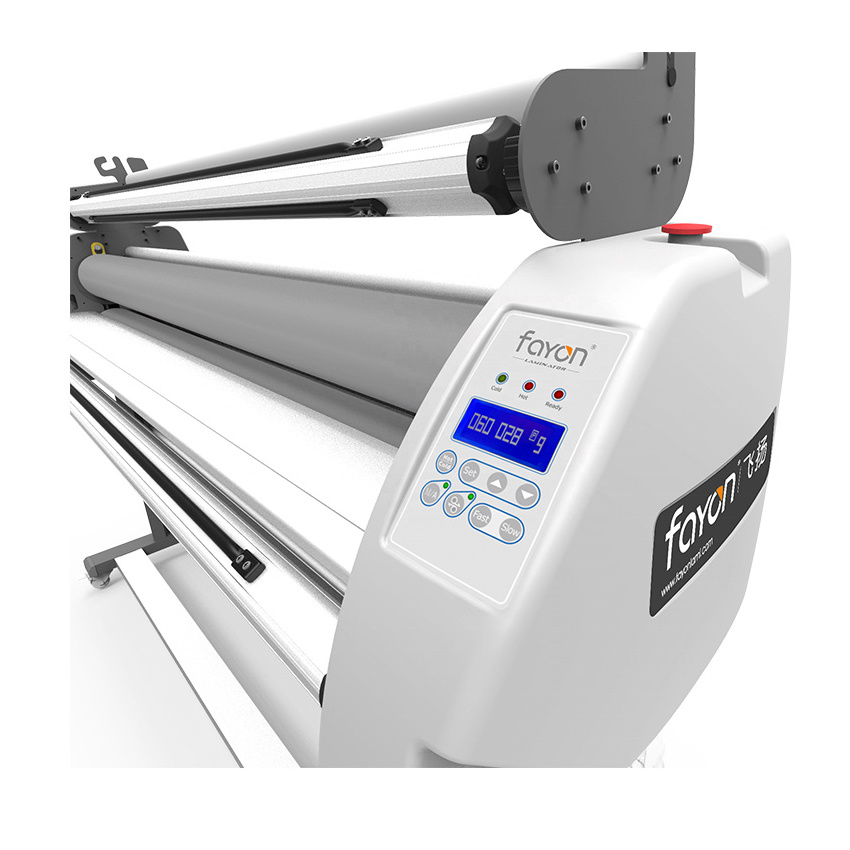

63inch Automatic Laminating Machine Vinyl Hot and Cold 1600mm Roll Laminator

> There, max laminating width is 1.62m, max working speed is

10m/min, processing thickness is 35mm, max thermal to 60 Celsius. Roller going up and down is controlled by handle valve with air cylinder. It’s pneumatic. So compressor will follow this machine.

|

The Parameters

|

|

|

|

TYPE

|

FY-1600DA

|

|

|

Main Structure

|

Heavy steel main frame+ Alloy Aluminum Tube+ABS plastic

|

|

|

Net Weight

|

190kg

|

|

|

Roller

|

130mm Heat resistant silicone (60℃)

|

|

|

Machine Legs

|

2mm Steel Plate

|

|

|

Machine chassis

|

5mm thickness steel plate+ABS plastic cover

|

|

|

Power Requirement

|

0.8kw-2.5kw

|

|

|

Motor Power

|

120w

|

|

|

Materials fit

|

Traditional cold film + Liner less cold film

|

|

|

Max Working Size

|

1620mm

|

|

|

Max Working Speed

|

10m/min

|

|

|

Processing Thickness

|

35mm

|

|

|

Power Supply

|

110/220v 50/60hrz

|

|

|

Roll loading position

|

4

|

|

|

Lifting way

|

Mechanical hand valve

|

|

|

Heating Function

|

Room-60℃

|

|

|

Cutting system

|

Removable supporting Bar

|

|

|

Materials loading tension system

|

Available

|

|

|

Packing dimensions

|

2270mm*770mm*740mm

|

|

Advantages:

* Fully automatic hot/cold laminating machine.

* Intelligent control panel, display plus control.

* Large 130 mm diameter rollers for optimum laminating control quality.

* High-quality silicone rubber rollers with a mounting thickness of up to 35 mm.

* Maximum laminating width - 1600 mm (63").

* Capable of single-sided hot or cold lamination, low-temperature heat-assisted cold lamination.

* Heated top laminating rollers to 60℃.

* Footswitch control for hands-free operation. Variable laminating speed up to 10 m/min.

* Simple and easy-to-use control panel for easy loading of film supply spindles.

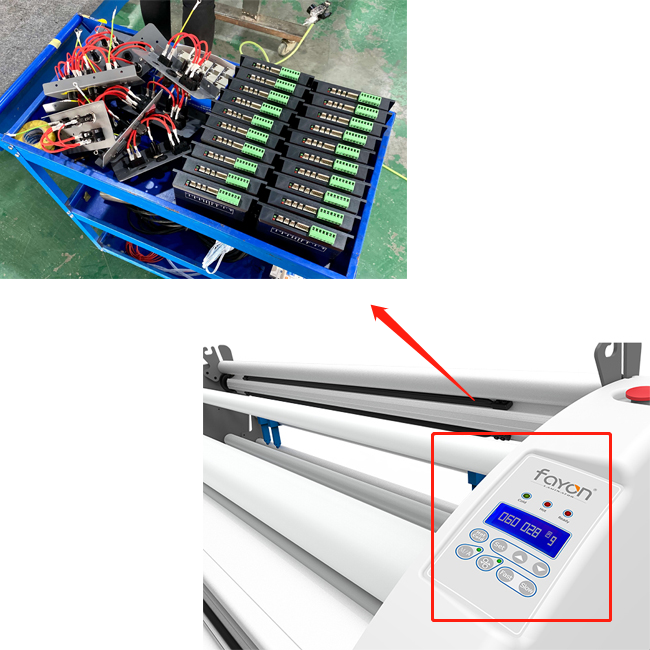

* Fuses Essential design with the internal circuit breaker box.

* Main roll sensor safety system, emergency stop override button.

Details Images

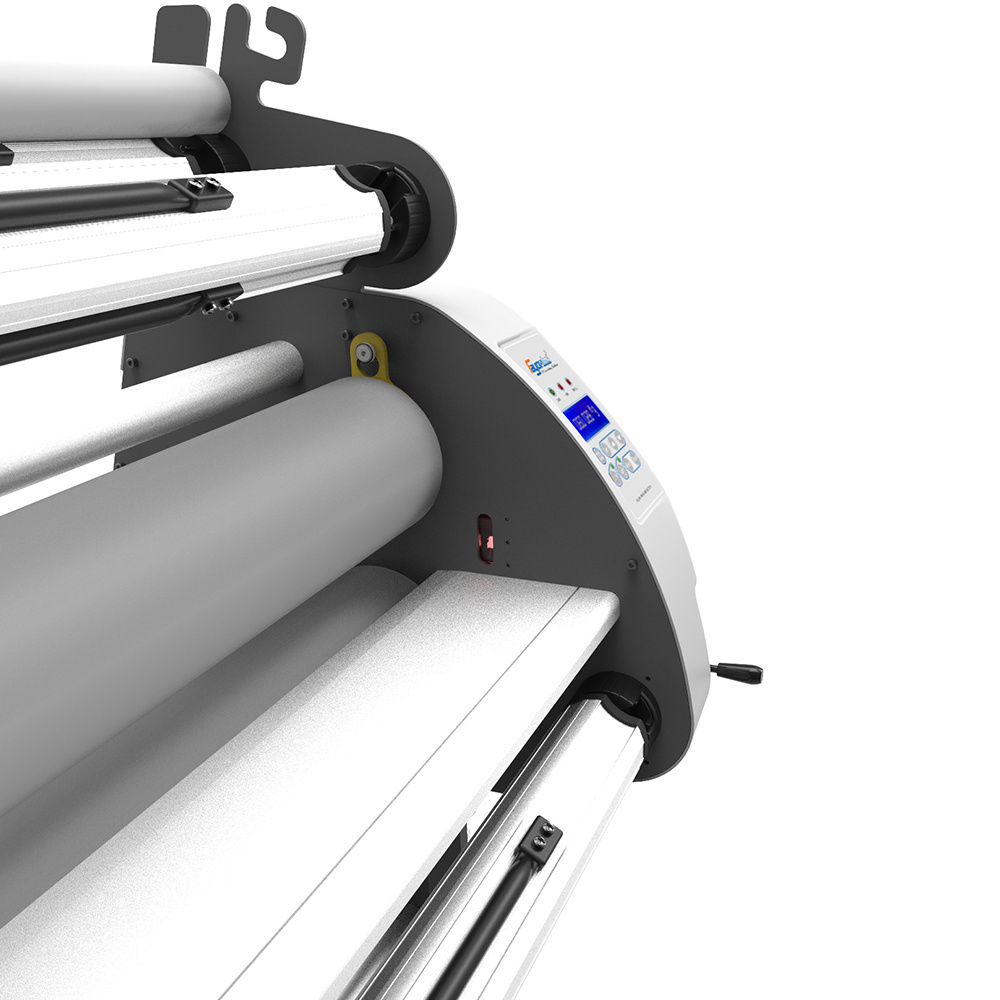

Function:

* Shutdown protection

* Correction function

* Anti-crease device

* Bottomless paper composite

* Infrared device

* Silicone roller heating

This type of machine with the infrared detection function can monitor whether the operator's hand is mistakenly placed under the roller shaft to ensure safety.

This laminator machine equipped with 4 cutters on the back side.

Users can remove the white edge while laminating. Positions of cutters is adjustable. Also, cutter quantity can be fully cutomised.

Related products

Company

Henan Yingkai Tech. Dev. Co.,Ltd.

1. Established before 2006, more than 16 years of development.

2. Specialized in researching, developing, producing, and selling FAYON laminator and FAYON paper trimmer.

3. Developed a variety of unique structural designs and functions, and diversified products for you to choose from.

4. Our products have been sold to more than 30 countries and areas. With CE certificate, our quality is well received from customers worldwide. Till now, we have more than 10 agents in the USA, UK, India, Germany, Spain, Brazil, UAE, and so on.

Certificate

Exhibition

FAYON laminator has participated in more than 10 exhibitions around the world. During the exhibition, we met with agents and customers all over the world, visited customers and provided them with technical service support.

Packing and Delivery

Delivery:

We have machine in stock for small qty order,can make delivery after clear the payment.

Big order, production time is less than 15--20 days , sending after clear the payment.

1. We will respond to your inquiry within 24 hours.

2. After shipping, we will track the products for you every two days until you receive them.

3. When you receive the goods, please test them and give me feedback. If you have any questions, please contact us and we will provide you with a solution.

FAQ

Q1. What are your terms of packing?

A: Generally, we pack our goods in a wooden case with a steel frame.

Q2. What are your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What are your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 7 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to our request?

A: Yes, we can produce the machine according to your request.

Q6. Do you test all your goods before delivery?

A: Yes, we have a 100% test before delivery

Q7. How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Hot Searches