- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZD

-

Voltage:

-

380V 50Hz 3phases or as your request

-

Dimension(L*W*H):

-

11000*1.2*1.4

-

Weight:

-

10 kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

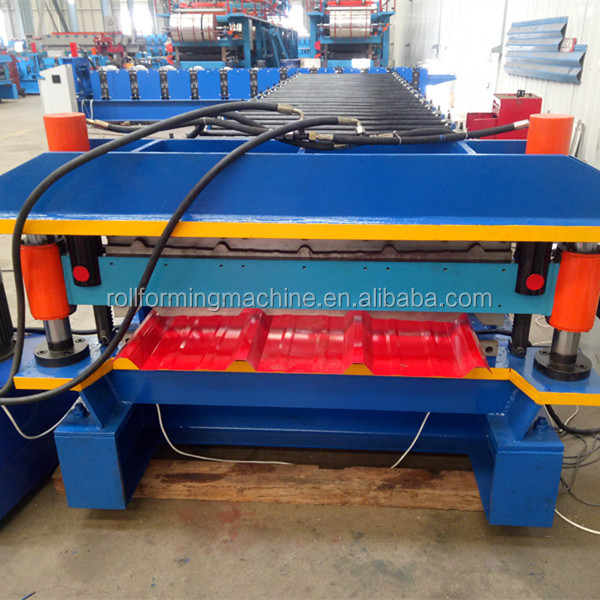

Color:

-

Blue Or According To Your Demand

-

Cutting System:

-

Hydraulic Cutting

-

Control System:

-

CNC/PLC Control

-

Key word:

-

high quality down pipe forming machinery

-

driving of roll forming machine:

-

by chain and gear box

-

Diameter Of Shaft:

-

75-90mm

-

Material of rollers:

-

45#steel Forge

-

Usage:

-

Roofing Accessories

-

After Warranty Service:

-

Video technical support

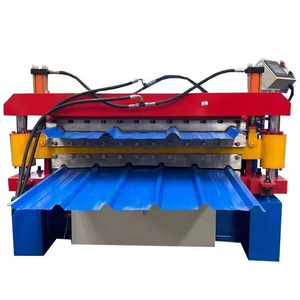

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-25meters/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZD

-

Voltage:

-

380V 50Hz 3phases or as your request

-

Dimension(L*W*H):

-

11000*1.2*1.4

-

Weight:

-

10 kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Blue Or According To Your Demand

-

Cutting System:

-

Hydraulic Cutting

-

Control System:

-

CNC/PLC Control

-

Key word:

-

high quality down pipe forming machinery

-

driving of roll forming machine:

-

by chain and gear box

-

Diameter Of Shaft:

-

75-90mm

-

Material of rollers:

-

45#steel Forge

-

Usage:

-

Roofing Accessories

-

After Warranty Service:

-

Video technical support

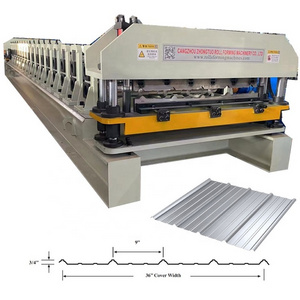

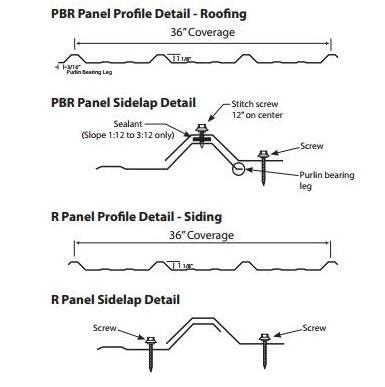

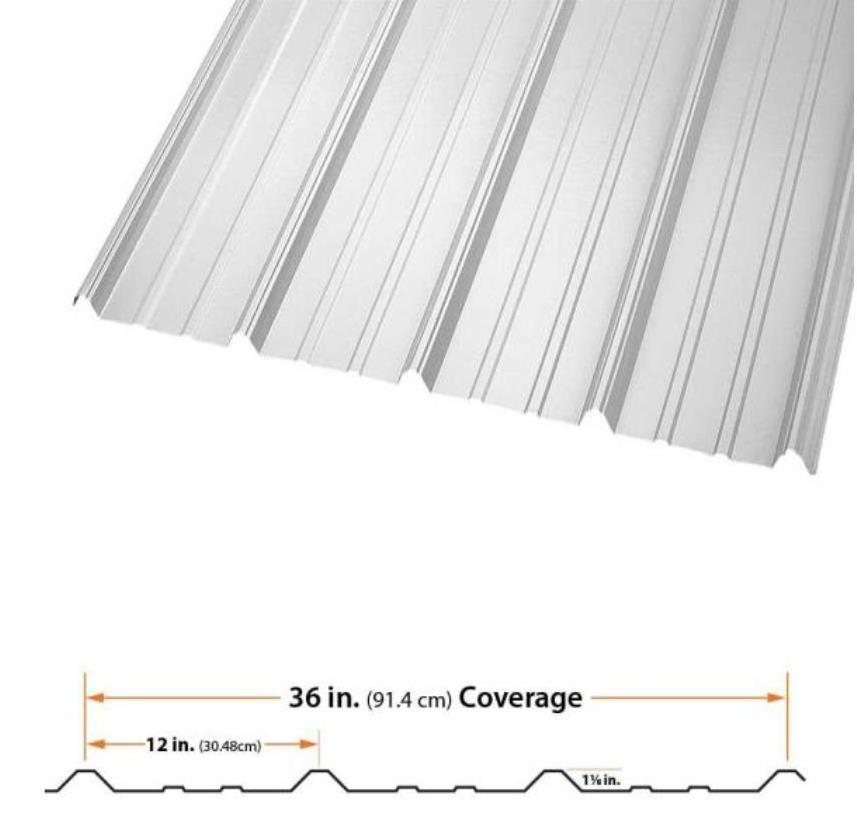

PBR Roof Panel Roll Former For USA Market

r panel is very common at USA market.

Picture show

The R Panel is a low-maintenance, durable metal roofing alternative to conventional roofing. It's ideal for retro-fitting over existing composition shingles with 36inch cover width, and it saves time, labor and disposal costs, which means a lower total project cost. Choose from many designer colors for a sleek, attractive appearance.It is a popular in USA.

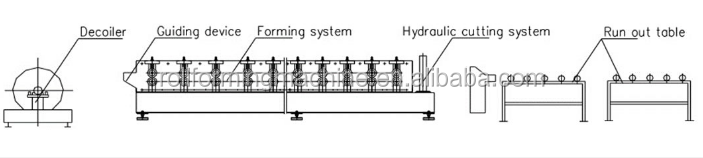

Flow chart:

Decoilling the sheet--sheet guilding--film covering--roll forming--measure length--cutting the panel--panel to the supporter

Specifications of r panel roll forming machine

1.PLC computer control

2.no noise,no shake

3.hydraulic system,long operating

4.easy operation

5.maintenance-free

Supplying components of

complete machine

| NO. | Description | Quantity (set) | Remark |

| 1 | 15,000 Lb manual decoiler | 1 | |

| 2 | Guiding device | 1 | One complete unit as main machine |

| 3 | Pre-MANUAL cutter | 1 | |

| 4 | Forming system | 1 | |

| 5 | Transmission system | 1 | |

| 6 | Hydraulic guillotine | 1 | |

| 7 | Support table | 2 | |

| 8 | Hydraulic station | 1 | |

| 9 | Control box | 1 | |

| 10 | Spare parts and tools | 1 | As attaching list |

- This machine is made up of roll forming machine,cutting machine,PLC computer control and hydraulic system

- The machine is stable,no noise,no shake

- Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable, maintenance-free

- cutting machine is characterized by stable driving, easy operation

- hydraulic system use the CDF-10 hydraulic pump, long operating life,no noise

- this machine is applies to roof fortification

General parameters

| No | Item | Parameter | Note |

| 1 | Forming Speed | 55-57 feet per minute | Excludes cutting |

| 2 | Forming station | Around 16 groups | |

| 3 | Power requirements |

Main motor power:10HP

Hydraulic motor power:4HP |

|

| 4 | Total Weight | Abou13500 Lbs | |

| 5 | Voltage | 440v,60hz,3p | |

| 6 | Diameter of shaft | 3inch | |

| 7 | Installation Size | 25.5feet *5.2 feet*4feet(L*W*H) |

Our Services:

♦ GUARANTEE:

12 MONTHS GUARANTEE. IF SOME PART OF THE MACHINE IS BROKEN.WE WILL SUPPLY THE BEST PART, BUT IF THE DAMAGED PARTS DUE TO OPERATE ERROR, BUYER WILL PAY FOR THE SHIPPING FEE.

♦ AFTER-SALE SERVICE:

WE SENT TECHNICIAN TO YOUR COUNTRY TO FIX THE MACHINE.THE BUYER SHOULD BEAR ALL THE COST INCLUDING:VISA,ROUNDTRIP TICKET AND SUITABLE ACCOMMODATION,ALSO BUYER SHOULD PAY THE SALARY 100USD/DAY.

FAQ:

1. How to play order:

Inquiry---confirm the profile drawings and price---confirm the PI---arrange the deposit or L/C---then OK

2. How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi(1 hour),then we can pick up you.

Fly to Shanghai Airport:By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5hours),then we can pick up you.

3. When we exported the machines:

We have beening making and exporting the machines since from the year of 1998.

4:If you want to get more pictures or videos of the machines,I can send them to you by Email or Skype