- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

600

-

After-sales Service Provided:

-

No overseas service provided, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Place Of Origin:

-

ZheJiang

-

Model Number:

-

Radiator Separating Machine

-

Speed Reducer:

-

2 Sets

-

Band Saw:

-

Available

-

Voltage:

-

380v or Customized

-

Frequency:

-

50Hz/60Hz

-

Output:

-

3t(one day)

-

Manual:

-

English&Chinese version

-

Machine Type:

-

Scrap Metal Shredders

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Chile, UAE, Colombia, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Canada, Turkey, United States, Italy, Philippines, Indonesia, India

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BSGH

-

Power (kW):

-

7

-

Weight (KG):

-

600

-

After-sales Service Provided:

-

No overseas service provided, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Place Of Origin:

-

ZheJiang

-

Model Number:

-

Radiator Separating Machine

-

Speed Reducer:

-

2 Sets

-

Band Saw:

-

Available

-

Voltage:

-

380v or Customized

-

Frequency:

-

50Hz/60Hz

-

Output:

-

3t(one day)

-

Manual:

-

English&Chinese version

-

Machine Type:

-

Scrap Metal Shredders

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Chile, UAE, Colombia, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Canada, Turkey, United States, Italy, Philippines, Indonesia, India

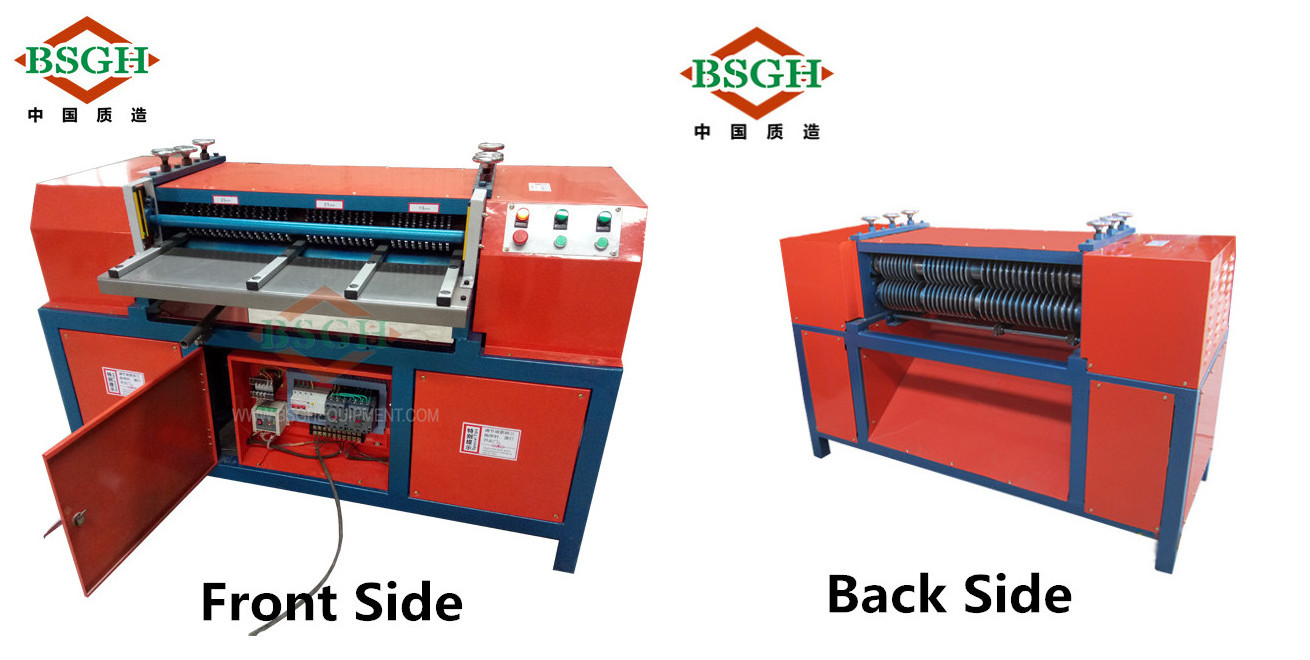

High Quality of the Copper And Aluminum Separator Machine Made In China

Product Description:

This machine is consisted of a frame, two speed reducers,material feeding part, material separation part,transmission part and material feeding panel.

BS-1200P is an environment-friendly equipment,used for separating copper pipes from aluminum,Designed and manufactured by us ,this machine is a newly-designed compact one ,taking up small area. Little materials will be lost during processing , so this machine is practical and economical.

Machine Parameters

Motor: 3kw (One Set) + 4kw (One Set)

Speed Reducer: 2 Sets

Voltage: 380v or Customized

Frequency: 50Hz/60Hz

Triangle belt: A Type (1200mm); B Type (1200mm)

Centerline of two copper pipes in radiators shall be 19mm or 21mm or 25mm.

G.W./N.W.:650/600KG PACKING SIZE:1.8*0.95*1.3 OUTPUT:3T(8HOURS)

| control | protect |

single and double radiator changing |

output | blade changing frequency | |

| BS-1200P |

electric control box |

all closed |

by handle (more convenience) |

3t/day |

about 300T, only need to change less blades |

processing:

1. Turn the Reversing Switch and check the rotating direction.

2. Inject oil into the two oil holes in the left and right side of the machine to lubricate transmission gears (normally once per 4 working hours).

3. Push different radiators into different Material Inlets according to their specs (19mm, 21mm, 25mm); the left side of radiators must touch the left side of Material Inlets; or, the right side of radiators must touch the right side of Material Inlets (the first copper pipe in the Lower Layer shall be nearer to the Guiding Ruler, different with 5 .6); when radiators are pushed into Material Inlets, Feeding Gears will gnaw at radiators and take them into the machine.

4. After radiators are taken into the machine, copper pipes and aluminum are separated and come out of the machine automatically.

5. According to the layers of radiators and their height, adjust each pair of Adjusting Wheels on the machine (after adjusting, tighten screws below ).

Packing&Shipping:

We choose the plywood case packing as export standard to pack the machine, and professional package to protect the machine,You may trust our package and us.

our company:

Xi'an Grand Harvest Equipment Co. Ltd. is specializing in various recycling equipment, including cable recycling machines (such as cable stripper machines and cable granulator machines) and other recycling machinery (likeradiator recycling plants and so on).

We have many years' experience in the recyclingfield, and also have more than 7 years' Aliaba sales experience. We have many superior-quality customers from overseas.

We pursue to supply our customers with excellent quality and outstandingservices.

we are committed to every aspect of our business.

We gratefully honor our commitments to our customers,our employees, our investors, our associations,communities and trade.

We seek excellencein all we do.

Certification:

contacts: